Wärtsilä Marine leads the industry in its journey towards a decarbonised and sustainable future. Our portfolio of engines, propulsion systems, hybrid technology and integrated powertrain systems deliver the reliability, safety, and environmental performance to decarbonise the worlds fleet. We offer our customers performance-based agreements, lifecycle solutions, and an unrivalled global network of maritime expertise.

Articles

Webinars

Whitepapers

Case studies

Lifecycle Agreement for Viking Supply Ships PSVs means smooth sailing whatever the weather

In 2021 Swedish operator Viking Supply Ships signed a five-year Technical Management Agreement (TMA) covering two modern, hybrid LNG-powered platform support vessels (PSVs). Both feature a wide range of Wärtsilä technologies including dual-fuel engines, fuel supply systems and a hybrid battery power supply system. The comprehensive, flexible TMA helps keep all this equipment running smoothly and means Viking Supply Ships have access to the support they need, whenever and wherever they need it.

Viking Supply Ships’ state-of-the-art PSVs, Coey Viking and Cooper Viking, are used to transport cargo to and from offshore oil and & gas platforms in challenging sea conditions and in areas with some of the world’s strictest emissions regulations. Both are packed full of Wärtsilä technologies that make them highly efficient and sustainable.

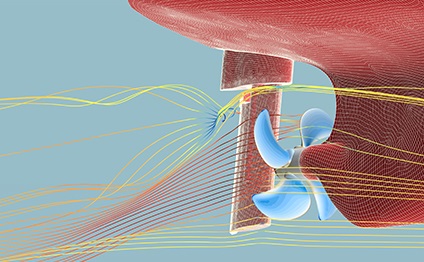

They are powered by Wärtsilä 34 and 20 dual-fuel engines and have the Wärtsilä LNGPac storage and handling system installed, allowing them to operate primarily on the low-carbon fuel. The vessels both feature a Wärtsilä HY hybrid battery power supply system, which Viking Supply Ships chose to retrofit to ensure that the vessels meet future environmental requirements and are an even more attractive prospect for charterers. They are also fitted with a Wärtsilä shore connection solution, which eliminates exhaust emissions and noise pollution in port and allows the onboard batteries to be recharged when required.

“Viking Supply Ships is a pioneer in terms of developing its operations in a more energy-efficient and environmentally sustainable direction, and we are delighted to be partnering with them to support their efforts,” says Trude Stene, Country Manager, Contracts, Wärtsilä Norway. “In this case there are only two vessels under agreement, but they receive the same care and attention as larger customers with agreements covering a far higher number.”

Lifecycle services agreement lays the groundwork for a strong partnership

To ensure their vessels operate optimally around the clock, in 2021 Viking signed a five-year Technical Management Agreement (TMA) with Wärtsilä. “The TMA’s comprehensive scope covers the engines, generators, electric motors, gas valve units, LNGPac system, hybrid system and electrical and automation systems,” explains Morten Tveit, Contract Manager, Wärtsilä Norway. “It’s a flexible first step on the lifecycle services agreement ladder that gives customers the peace of mind they need while putting them in the driving seat in terms of maintenance planning and execution,” he continues.

We are very pleased with the way the agreement has been working so far. For me, one of the most important benefits is that we can solve a lot of issues remotely without the time and expense associated with having a technician sent out to the vessel. In the whole of 2023 we only needed to call out a Wärtsilä technician once for one of the vessels and not at all for the other.

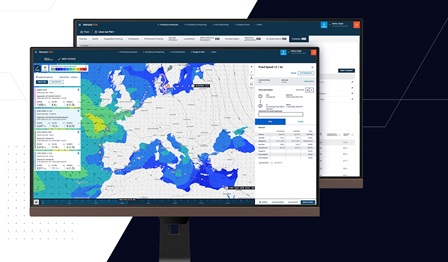

This kind of remote support is possible because the TMA includes the Wärtsilä Expert Insight service, which uses cutting-edge artificial intelligence and advanced diagnostics to spot potential problems before they can develop into major issues that result in costly downtime. If an issue is flagged, a dedicated expert at Wärtsilä’s Expertise Centre can liaise with Viking Supply Ships’ crews to provide actionable recommendations and guidance.

Because of the vessels’ relatively unpredictable schedules and working locations, and to ensure crews have support available whenever they need it, on-demand remote operational and technical support are also included, covering the engines and electrical and automation equipment.

Viking Supply Ships can also call on Wärtsilä for a wide range of other services, as Tveit explains: “On a purchase-order basis we can supply any needed spare parts for overhauls or other scheduled maintenance, field service technicians to perform the work, workshop services for repairs, component overhauls and annual inspections of gas valve units and the LNGPac system. Naturally, we know the vessels and their equipment and systems inside out, so the customer can trust us to deliver top-quality service every time.”

Supporting engine optimisation and the transition to alternative fuels

The TMA is not only benefiting Viking Supply Ships in terms of solving problems or preventing them from happening in the first place; it also provides them with a direct line to Wärtsilä experts when they need advice or want to discuss how to optimise a vessel’s performance. “These are exceptionally complex ships with components and systems that need tuning, adjusting and checking periodically. With the TMA we have all the data we need at our fingertips and can use that data to discuss with Wärtsilä about how to optimise vessel operation,” explains Jan-Erik.

Just like their peers in the maritime industry, Viking Supply Ships is also actively exploring the opportunities offered by alternative fuels, such as ammonia. This is an area where, as part of their partnership, Wärtsilä has also been offering support. “We have been performing feasibility studies to investigate ammonia as a fuel and what converting the vessels would mean in practice,” Jan-Erik explains. “Thanks to the TMA we have extremely reliable data that we can use to analyse the vessels’ operational profiles and do the maths on the fuel conversions. Beyond this, we have also used the data to optimise the use of the Wärtsilä HY hybrid system with support from Wärtsilä’s experts.”

Trust built on transparency

The excellent working relationship with Viking Supply Ships is the result of world-class engineering expertise – and plenty of time and effort – on both sides. “We hold weekly meetings to make sure everyone’s on the same page and to address any issues. These open, honest discussions help us tremendously in terms of strengthening our partnership and ensuring that the TMA is providing everything that the customer needs,” says Tveit.

As Stene explains, a TMA is often the first step on the road to a more comprehensive type of agreement where Wärtsilä can take on even more risk and responsibility on the customer’s behalf: “Viking Supply Ships is a very forward-thinking organisation that is always looking to improve. They have a highly professional, vastly experienced in-house team, which is why the TMA was the right first step for them. It provides a safety net and peace of mind, with world-class OEM support plus the option to buy in additional services as and when they need.”

“The knowledge we gain about the vessels’ performance and behaviour every day have been extremely valuable as we seek new ways to develop our partnership. This could be in the form of, for example, setting mutually agreed targets for KPIs like engine running hours, uptime or emission levels.

We are taking decisive action to future-proof our assets by preparing them for next-generation fuels and battery technology while maintaining safety and efficiency. With such advanced vessels it was important to ensure that our crews had good technical support to help them build their competences and gain confidence in the new assets. With the TMA we have a direct line to technical experts through our contract manager and the Wärtsilä Expertise Center, so our chief engineers can discuss any issue directly with an expert while looking at the same data they see. Our relationship with Wärtsilä is essential to secure a successful transition to a more energy-efficient and less carbon-intense future. With Wärtsilä’s help, we are investigating ammonia as a potential alternative fuel to LNG.

The technical management agreement gives us a direct line to Wärtsilä’s technical experts for remote problem solving and advice. The data we can now gather is invaluable for engine optimisation and the transition towards less carbon-intensive vessel operations.

Ensure optimal operation 24/7 for two newly retrofitted hybrid PSVs.

Five-year Wärtsilä Technical Management Agreement including Wärtsilä Expert Insight service for remote diagnostics and troubleshooting.

Peace of mind with reliable vessel operation and expert technical support for crews, plus support with hybrid system optimisation and potential transition to ammonia as fuel.