This podcast was generated with AI based on a human-written text (the Source text further down on the page). The list of key takeaways was generated with the help of AI based on the same, human-written text.

Key takeaways

There are four expert strategies for future-proofing a newbuild vessel.

- Flexible vessel design is essential for future-proofing ships, because it makes the adoption of new technologies easier throughout their lifespan.

- Ship electrification and batteries help maximise ship efficiency. Engines can run at optimal load more often, and batteries balance power demand fluctuations.

- Dual-fuel engines provide fuel flexibility. Vessels can operate on traditional fuels, LNG, biodiesel, bio-LNG, and future synthetic fuels with minimal or no modifications.

- Methane slip reduction technologies like Wärtsilä's NextDF significantly lower emissions from LNG-powered vessels, reducing methane slip to approximately 1% of fuel use—well below the FuelEU Maritime regulation of 3.1%.

Source text

Four top tips for future-proofing your newbuild vessels

Future-proofing your newbuild vessels is a highly effective way to make sure they keep delivering emissions reductions throughout their operational lifespan. By making thoughtful decisions during the design phase, you can achieve the best possible emissions performance for your newbuild.

A vessel that’s easy to modify means you can take advantage of new efficiency-enhancing technologies as they become available – as well as giving you the opportunity to switch to more sustainable fuels when the time is right.

Today it seems that cutting greenhouse gas emissions like methane slip – the name given to the unburned methane that escapes into the atmosphere from LNG-powered vessels – is a top priority for vessel owners as LNG is the most common alternative fuel in the market. Building in flexibility right from the design stage is critical to make sure your newbuild vessels meet their emissions targets throughout their operational lifespan and ensures they are ready for a fuel-flexible future.

1. Flexible design allows easier adoption of new technologies

A newbuild vessel could be in operation for 20 or even 30 years, so building in flexibility and modularity as early as possible in the design phase is a great way to make sure you are ready to adopt new technologies as they become available.

This means considering the design of your vessel’s structure and systems carefully in order to make upgrading as easy and quick as possible. For example, things like cabling and piping routes, should be designed in such a way that they are easy to access and modify when needed. And of course, keeping in mind space reservations and supporting structures for an additional fuel supply when another, greener fuel might be introduced.

2. Electrification is a key enabler

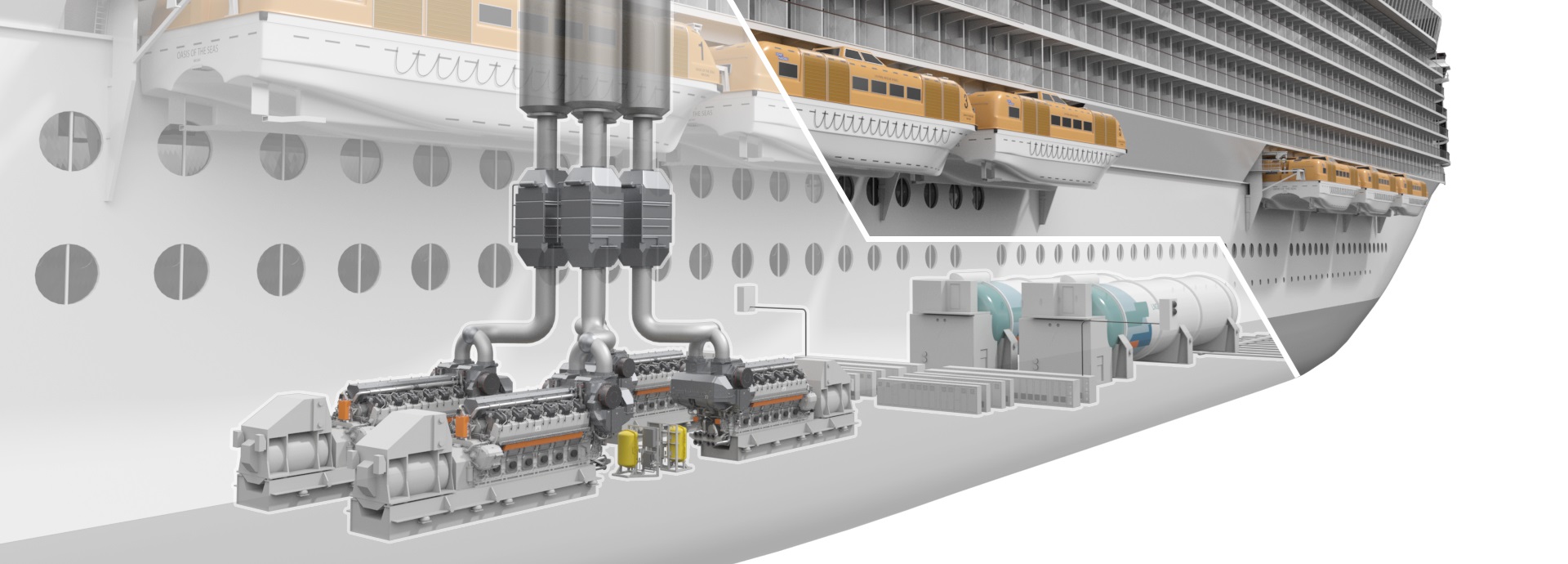

Adopting electrification, for example by choosing a diesel-electric propulsion system with batteries, is another excellent way to future-proof your vessel. This type of system gives you the flexibility to add new power sources and manage power distribution and consumption optimally for maximum efficiency. Combining a conventional engine with an energy storage system allows the engine to run at optimal load while the battery balances fluctuations in power demand. Some may criticize that batteries take a lot of space onboard, but the battery technology has evolved and continues to evolve so fast that this is not a concern compared e.g. to the previous decade.

3. Fuel flexibility keeps your options open

As the maritime industry continues its journey towards the goal of zero-emission operations, dualfuel engines have been playing a key role by enabling fuel flexibility. Many operators that have adopted dual-fuel engines are operating with a combination of diesel and LNG, or bio-versions of them. This setup provides plenty of options since the engines can burn traditional fossil fuels, biodiesel and bio-LNG, and will be able to burn even more sustainable synthetic versions of these fuels in future. And all this can be done without making big, or even any, changes onboard. Small steps, but a big end-result in terms of efficiency and emissions reduction.

4. Field-proven technologies to reduce methane slip

Today it seems that cutting greenhouse gas emissions like methane slip – the name given to the unburned methane that escapes into the atmosphere from LNG-powered vessels – is a top priority for vessel owners as LNG is the most common alternative fuel in the market. While LNG has great potential as a natural bridge between traditional fossil-based marine fuels and sustainable alternative fuels, the challenge of methane slip still exists. Methane slip is an issue that Wärtsilä has been working hard to address for decades. And there are great solutions that drastically reduce your newbuild’s methane emissions compared to the traditional ones.

A great example of emission reduction technologies for dual-fuel engines is the Wärtsilä’s NextDF. NextDF is an innovative combustion technology that dramatically reduces methane slip and minimises emissions of nitrogen oxides, carbon dioxides, and other pollutants. It does this by improving combustion control and optimising engine performance. As an example, NextDF technology can reduce methane slip by 61% for the Wärtsilä 31DF engine compared to a standard 31DF engine. One of these NextDF engines has been in operation already for many years and its great performance has been tested and validated by the VTT Technical Research Centre of Finland.

Choosing a NextDF engine can reduce methane slip to around 1% of fuel use – a figure well below the FuelEU Maritime regulation of 3.1% of fuel use. NextDF engines significantly reduce emissions while still providing the same, high power output as before. And what’s best, the NextDF technology is nowadays available already for 3 different engine sizes meeting various power needs of different vessel applications. So, if you are considering a newbuild I strongly suggest you look first at the option of using LNG as fuel and then definitely at this new, revolutionary Wärtsilä technology that will significantly reduce methane emissions from your LNG-powered vessel.