This podcast was generated with AI based on a human-written text (the Source text further down on the page). The list of key takeaways was generated with the help of AI based on the same, human-written text.

Key takeaways

Improving a vessel’s propulsion efficiency with energy-saving technologies will save fuel and therefore cut methane slip.

- Combining technologies maximises results. For example, install an energy-saving propeller cap (like Wärtsilä’s EnergoProFin) and a pre-swirl stator (like EnergoFlow) and you can achieve up to 6% fuel savings.

- Redesigning propellers using computational fluid dynamics (CFD) will offer significant efficiency gains, particularly for vessels that use slow steaming or require higher speeds.

- GATE RUDDERTM is an innovative technology that can can deliver up to 20% fuel savings while improving manoeuvrability and reducing noise.

- Energy-saving technologies are a future-proofing strategy. Implementing these technologies helps vessels prepare for sustainable alternative fuels, which will remain more expensive than fossil fuels for years to come.

Source text

Three amazing ways to reduce vessel propulsion power and cut methane slip

Adding energy-saving technologies to your vessel reduces the amount of energy it takes to push it through the water. Less energy spent means less fuel used – and lower methane slip. What technologies are available, and how can they be combined to maximum effect?

Reducing the amount of power it takes to propel your vessel through the water is a fantastic way to address the issue of methane slip – the small amount of unburned methane that escapes into the atmosphere from LNG-powered vessels. When your vessel is more efficient, it will use less fuel and produce less emissions overall.

What are the smartest ways to make your vessel as efficient as possible, and how can you combine them to maximise fuel savings and have the biggest possible impact on methane slip?

Reduce emissions by as much as 25% with energy-saving technologies

Energy-saving technologies like rotor sails and efficiency-boosting add-ons like propeller caps and pre-swirl stators are just a few examples of proven ways to improve vessel efficiency. These solutions are relatively inexpensive, quick to install and can have a very short payback time.

Energy-saving technologies give you a way to future-proof your vessel ready for more sustainable alternative fuels, which will continue to be more expensive than fossil-based fuels for some years yet.

The trick to ensuring compliance with emissions regulations and maximising the fuel savings from energy-saving technologies is to find exactly the right combination of solutions for your vessel. So, what are your options?

1. Combine an-energy-saving propeller cap with a pre-swirl stator

An energy-saving propeller cap like the Wärtsilä EnergoProFin can reduce the amount of energy needed for propulsion by between two and five percent. The fins on the propeller cap rotate together with the propeller, weakening the propeller hub vortex and recovering kinetic energy from the rotating flow behind the propeller blades. This kind of energy-saving technology reduces energy losses and increases your vessel’s overall propulsive efficiency.

You can combine an energy-saving technology like the EnergoProFin with a pre-swirl stator like the Wärtsilä EnergoFlow for even greater efficiency gains. Wärtsilä EnergoFlow improves your vessel’s propulsive efficiency by creating an optimal inflow for the propeller, preventing the power losses that typically occur in a propeller’s slipstream. It does this by guiding one side of the stern flow against the direction that the propeller is rotating in, generating pre-swirl. The stator consists of multiple curved fins and a ring attached your vessel’s hull.

Both these solutions are suitable for newbuild and existing vessels. To give you a scale, there is one Wärtsilä’s customer who has achieved an amazing fuel consumption saving of 6% by combining these energy-saving technologies. For them that translates into 16 days of fuel-free operation and a reduction of more than 2,000 tons in CO2 emissions.

2. Install a redesigned propeller

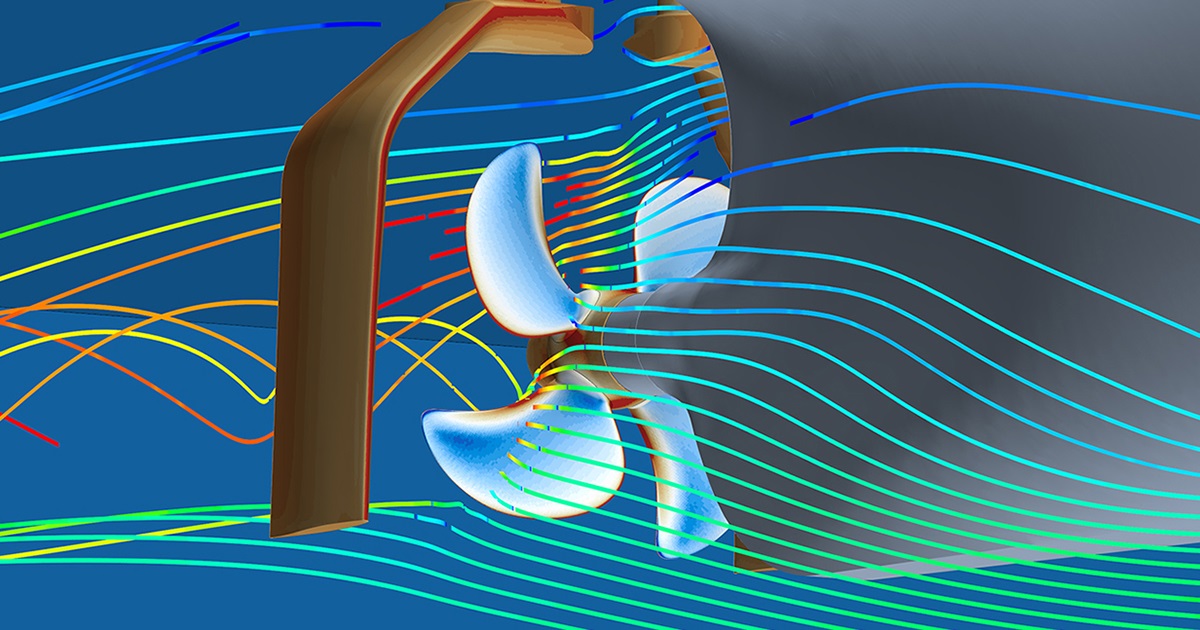

Redesigning your vessel’s propeller with the help of computational fluid dynamics, or CFD for short, is another winning tactic to achieve significant efficiency gains – especially if your vessel uses slow steaming to save fuel. If you operate a fast ferry, you can achieve higher speeds and efficiency gains by modifying the vessel’s controllable pitch propeller.

Wärtsilä can help you realise these gains and reduce methane slip with its Optidesign approach.

This methodology aims to perfectly match the propeller, engine and hull using CFD calculations that take both propeller performance and the interaction between propeller and hull into account.

3. Use innovative gate rudder technology

A gate rudder is an energy-saving device that is particularly appropriate for newbuild vessels. This technology reduces your vessel’s fuel consumption by replacing the drag of a traditional rudder system with a thrust-enhancing arrangement. A gate rudder comes with the added benefits of better vessel manoeuvrability and a lower noise and vibration signature.

GATE RUDDERTM by Wärtsilä has a unique design comprising two foils on either side of the propeller. During transit, the foils can rotate their angular position to optimise the hydrodynamic load on both propeller and foils; for manoeuvring purposes, the foils become a thrust-directing device. Vessels with this gate rudder installed have reported double-digit fuel savings.

If you’re looking for even more ways to reduce vessel propulsion power and methane slip, there’s a Wärtsilä eBook that you shouldn’t miss. “51 great ways the maritime industry could reduce its greenhouse gas emissions” includes 16 different ways to reduce the power needed for propulsion.