Ship owners and operators are under pressure to reduce costs without compromising ship reliability and performance – but ship maintenance can be expensive. Here are twelve simple ways to save money on ship maintenance.

In a hurry? Here are the six key takeaways

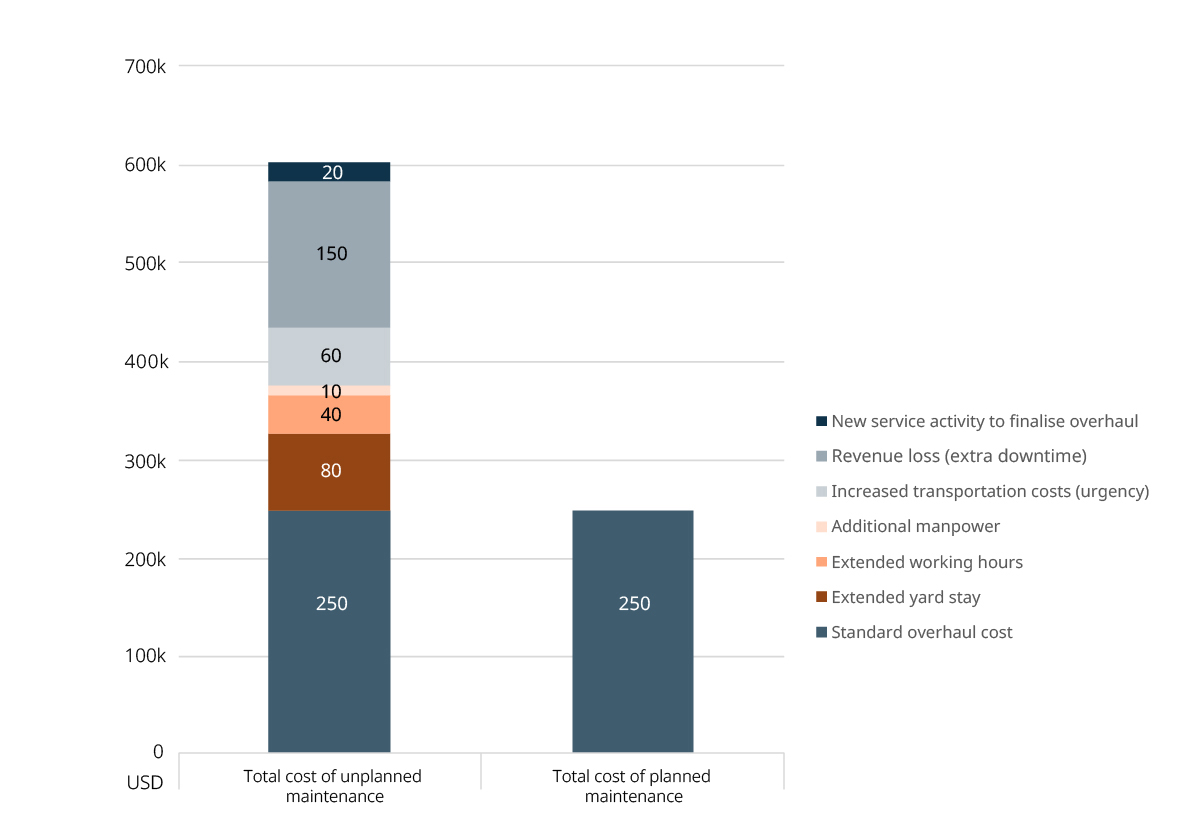

- Unscheduled maintenance can cost you up to 50% more than planned maintenance.

- Early planning is the best first step to ensure high-quality maintenance for the lowest possible cost.

- Involving your OEM service provider early gives you access to expert knowledge, ensures parts availability and helps avoid costly mistakes.

- It is essential to know the condition of your equipment and the state of your parts inventory – and it can save you money.

- Doing as much work as you can in the same dry dock period – including regular maintenance and lifecycle upgrades – helps you make the most of vessel downtime.

- Stay focused on long-term value, not short-term costs.

As a ship owner or operator, you want reliable operations without costly downtime. You also want to extend the lifetime of your ships. Regular maintenance and overhauls can improve reliability and minimise the risk of unexpected equipment failures, but are often expensive and time-consuming.

To ease your pain, here are twelve ways you can save money on ship maintenance.

- Start planning early

- Involve your service provider early on

- Check the condition of your equipment

- Reserve enough time for resource allocation

- Check your spare parts inventory

- Consider using reconditioned parts

- Perform upgrades and maintenance at the same time

- Optimise labour and delivery

- Focus on lifetime costs, not short-term savings

- Resolve minor problems before they become major issues

- Track the condition and performance of your assets

- Take a condition-based approach to maintenance

1. Start planning early

Regular maintenance and overhauls help safeguard you from unexpected failures. But regular maintenance requires planning – and planning should never be rushed. Doing everything at the last minute can lead to unexpected delays or budget problems. You can avoid these issues if you plan early and communicate with your stakeholders as early as possible.

Ideally you should start planning a regular maintenance or overhaul project at least six months before work is due to begin. For a major overhaul you should start planning around 12 to 18 months beforehand so that:

- your maintenance project will be more likely to run on time and on budget

- you can be more certain that the work will be done carefully and to the required standard

The more time you reserve for planning, the more opportunities you will have to fine tune your plan – and save money. A planned overhaul can cost around 50% less than unscheduled maintenance – as seen in Figure 1.

Figure 1: Example cost comparison of unplanned vs. planned maintenance

Handpicked related content:

Learn more about why maintenance planning makes sense in this white paper:

Ship maintenance: 5 strong reasons why you really need to plan it

2. Involve your service provider early on

If you wait until the day you are ready to order to send lists of parts and tasks to your service providers, you increase the risk of forgetting some items altogether. It’s also possible that some of the items you need have been updated without you realising, or in the worst-case scenario they are no longer available.

To reduce the risk of parts and skills being unavailable, and to keep the work on budget, involve your service provider early on.

You should also take full advantage of the extensive knowledge and experience that your original equipment manufacturers (OEMs) have. They know your equipment best and can tell you what must be done and what is just a ‘nice to have’, potentially saving you even more money.

It is important to have the most up-to-date information when you are defining your scope of work. If your information is outdated you may end up with too many or too few spare parts, or even the wrong parts altogether. Another problem might be that you are not able to find the right people with the right skills when you need them.

3. Check the condition of your equipment

Before carrying out maintenance, you should check the condition of your equipment. This can save you money because it reduces the risk of missing anything or carrying out extra or unnecessary work.

First, check your equipment’s maintenance history and logs. You can build a more complete picture by also checking service work reports for what has been carried out previously.

If the service history of your ship is unknown, you will need an audit or inspection to find out how your installation has been modified in the past. This will help you evaluate the condition of your equipment and decide what you need to do to overhaul and maintain it.

Handpicked related content:

Looking for practical tips on how to save money while keeping your ship operating reliably? Subscribe to the Expert tips newsletter:

Get expert tips for reliable operations

4. Reserve enough time for resource allocation

You need the right parts and the right people with the right skills in the right place at the right time. To ensure this happens, you need to reserve enough time for resource allocation. Leaving resource allocation to the last minute could lead to delays and unnecessary costs. Spare parts may also cost you more if you need to place an urgent order.

You also need to plan who does what. For example, when allocating resources think about what role your crew will play. Will they be helping with the maintenance or overhaul? If so, what will they do? For example, will they handle logistics inside the engine room as well as between the engine room and workshop? If people’s roles are not clear it can wreck the entire schedule – and your budget.

If you don’t match the right person with the right maintenance task you might spend more money than you need to. For example, it can take an hour to transport engine cylinder heads from deck to deck. It doesn’t make sense to give this job to qualified marine engineers because their hourly rates can be high.

Instead, you can allocate manual tasks like this to your crew. This can save you money and reduce the risk of errors and delays.

5. Check your spare parts inventory

Ask yourself: what do you need to order and what have you already got? It’s important to check your spare parts inventory well in advance of any maintenance work to have an accurate picture of what you have already paid for. This avoids unnecessary waste and expense.

Even if you already have all the parts you need in your inventory, remember to check their condition and make sure that they are still under warranty.

6. Consider using reconditioned parts

If your budget is tight, some OEMs can supply reconditioned, remanufactured or recalibrated parts that are ready to use immediately. For example, with the Wärtsilä Exchange Parts service you buy the reconditioned parts you need, install them and then return your old parts to Wärtsilä.

This avoids the need to wait for your old parts to be reconditioned before you can start the overhaul. Reusing parts saves you money, saves natural resources and reduces waste.

Handpicked related content:

Did you know that the spare parts you use on your ships can have a big impact on your emissions? Discover five surprising things that make your ship spare parts more sustainable

7. Perform upgrades and maintenance at the same time

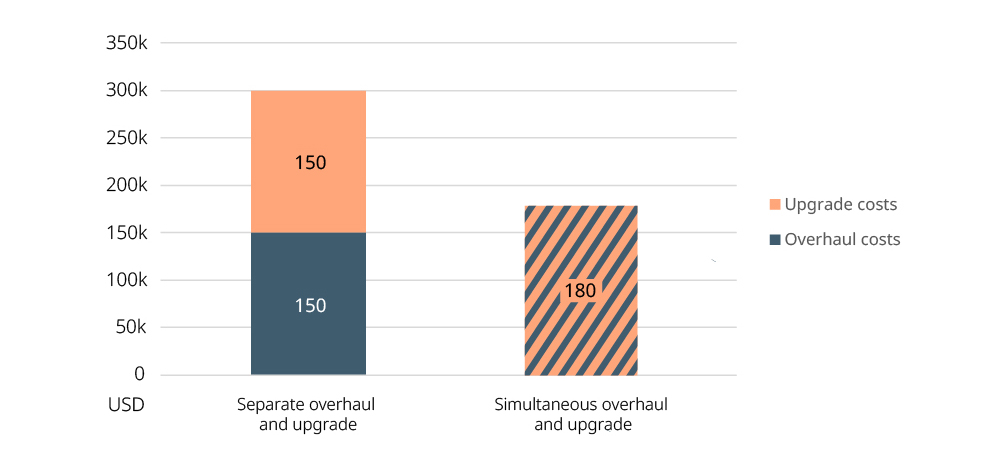

Performing lifecycle upgrades and regular maintenance at the same time will save you money.

For example, when you want to improve the efficiency and performance of your engine or other equipment, you should perform lifecycle upgrades when your ship is already in dry dock for maintenance. This saves you money because it allows you to do two things in the same downtime period.

Figure 2 shows the costs associated with planning and performing a turbocharger overhaul and upgrade separately compared to doing it at the same time.

Figure 2: Example cost comparison of unplanned vs. planned turbocharger maintenance

Because the turbocharger requires a complete overhaul at 48,000 running hours to keep it operating within acceptable safety standards, it makes sense to perform the turbocharger compressor upgrade at the same time. This is because the overhaul and the upgrade mostly use the same parts. This can bring you significant savings and immediately reduce your fuel costs.

8. Optimise labour and delivery

With enough time to plan properly you can optimise how your workforce operates, for example by having two shifts if downtime is tight. Or you could combine tasks in such a way that you can reduce the number of service technicians or experts needed, saving you even more money.

You can also optimise parts transportation. For example, instead of air freight you can use sea freight, which is usually the cheapest and most environmentally friendly option. Ordering parts at the last minute can mean they are more expensive to deliver, so getting your order in early helps keep your budget under control.

9. Focus on lifetime costs, not short-term savings

Maintenance or overhaul projects typically include a lot of different tasks, all of which need prioritising.

If your budget is tight, it can be tempting to prioritise these tasks based on cost. But focusing on cost alone can make the work more expensive in the long run. Instead, you should focus on lifetime costs rather than short-term savings.

For example, cheaper options might not include a warranty for maintenance work, leaving you to cover any additional costs. Some OEMs, including Wärtsilä, offer a 12–18 month warranty for spare parts; if the parts are installed by an authorised Wärtsilä field service expert the warranty may be even longer.

OEM spare parts can also last considerably longer than non-OEM parts, which can save you money.

Handpicked related content:

To learn why genuine parts are the best choice for your vessel, download the white paper:

Why genuine spare parts are the best choice for your vessel – 5+1 great reasons

10. Resolve minor problems before they become major issues

Predictive maintenance services like Wärtsilä’s Expert Insight offer another way to save money.

This type of service combines tools, expertise and data to detect anomalies early, so your crew can address them before they cause major, costly issues.

For example, Wärtsilä’s Expert Insight identified the start of a problem on board the shuttle tanker Aurora Spirit. Thanks to the early warning, the owners were able to avoid a costly and time-consuming engine failure – all with a simple bearing replacement.

11. Track the condition and performance of your assets

A performance management system like Wärtsilä’s Fleet Optimisation Solution (FOS) keeps you fully informed about the condition and performance of your assets, which can help you save money.

For example, FOS can monitor hull, propeller and engine condition in real time and notify crews of any anomalies. This helps you make better decisions about when and how to service your equipment. You can save money by scheduling maintenance when your vessel is out of operation, which minimises downtime and avoids disruption to your operations.

FOS also makes it easy to choose the optimal route and speed for your vessel according to the weather, wind, waves and currents. This can help you make big savings on fuel and emissions. FOS is already helping over 2,000 cloud-connected vessels to save money.

12. Take a condition-based approach to maintenance

Some OEMs offer complementary services like data-driven maintenance, which give you another way to save money. Data-driven maintenance is a method where maintenance is planned based on analysis of data from your vessel’s engine combined with in-person inspections. When you know the true condition of your assets, you don’t need to spend time and money changing engine parts just because a manual says so. Instead, parts can be changed when it makes most sense.

Using data in this way makes maintenance planning more flexible. You can extend overhaul intervals and maintain your vessel when it’s most convenient for you. This can help reduce the lifecycle costs of your engine.

Handpicked related content:

Learn how Wärtsilä’s data-driven maintenance planning helped Sapura Brazil to safely prolong maintenance intervals:

Optimised Maintenance agreement doubles time between drydocks for Brazilian pipe-laying vessels

Conclusion

Ship owners and operators want reliable operations and to avoid downtime, especially unscheduled downtime. Regular maintenance and overhauls can improve reliability and reduce the risk of unexpected equipment failures, but they can be costly and time-consuming – and do not always go as planned. Balancing the need for reliability with the need to save money can feel overwhelming.

The best first step is to start planning early. Proper planning helps you to get high-quality maintenance and repair work done in the shortest possible time and for the lowest possible cost. So, why not take the time to plan your maintenance and make your job easier?

This paper makes things easier for you. It gives you practical guidelines that will help you to make a maintenance plan that best suits your needs and perform high-quality maintenance and repair work in the shortest possible time and for the lowest possible cost.

How to make the best maintenance plan for your ship – the simple way.

This article listing 12 ways to reduce ship maintenance costs first appeared as a Wärtsilä Insights article.

Related solutions

Did you like this? Subscribe to Insights updates!

Once every six weeks, you will get the top picks – the latest and the greatest pieces – from this Insights channel by email.