Ship engine maintenance might seem like a costly and time-consuming task that simply cannot be avoided. But when it’s well planned, engine maintenance can run smoothly and bring significant benefits.

This article reveals the top four benefits of good ship engine maintenance practices.

1st benefit – You can avoid unpleasant, expensive surprises

When you take good care of your critical engine components, you can avoid many potential problems further down the line. For example, worn components can fail, causing more extensive and expensive problems later. What’s more, paying limited or no attention to critical components can compromise your fuel oil economy and negatively impact your operational expenditure (OPEX). It can also affect compliance and add to the associated costs.

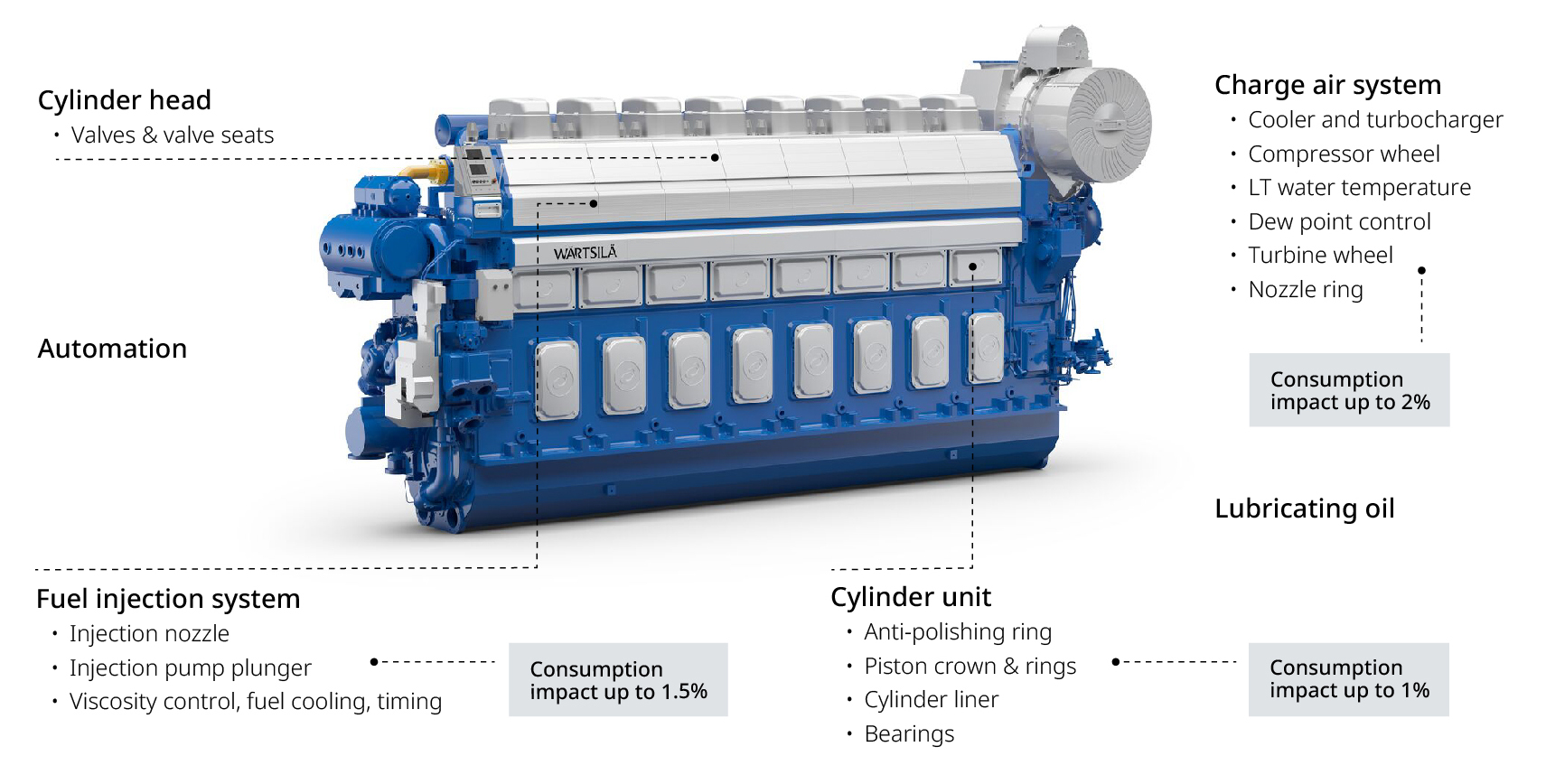

But which engine components are critical? Here’s a list of the four key component categories:

- Cylinder heads, including the valves and valve seats

- Injection equipment such as the nozzle and plunger

- Anti-polishing ring and piston-related components

- Charge air system, including the cooler, turbocharger and air intake.

Taking good care of these components will help you avoid many potential problems further down the line.

You can also optimise your engine performance with these simple housekeeping practices:

- Keep your engine’s charge air cooler and turbocharger clean.

- Monitor the back pressure after the turbocharger, especially if you have exhaust gas after-treatment systems installed.

- Keep the air filters clean and engine room ventilation in good working order.

- Regulate the charge air cooling capacity so that it remains as close as possible to the dew point.

- Control the fuel oil temperature – this affects the fuel’s viscosity, which is particularly important if you’ve changed to distillate fuel and have not adjusted the fuel oil cooling capacity.

2nd benefit – You can improve the reliability and efficiency of your engine

Good maintenance practices will help to optimise your engine’s reliability and efficiency.

For example, following good maintenance practices will help you avoid problems if your engine was originally designed to run on one type of fuel but now runs on another fuel.

Let’s say you switched from residual to distillate fuel – and did not increase the auxiliary cooling capacity to match the new fuel. The viscosity of the fuel may be unnecessarily low, which can delay fuel injection timing.

While this continues, components will wear out more quickly and the engine will consume more fuel. Good maintenance practices can help you avoid this problem.

Handpicked related content

Regular maintenance and overhauls do not always go as planned. Learn why maintenance planning is something you need to think about today – download this paper: "Ship maintenance: 5 strong reasons why you really need to plan it".

3rd benefit – You can save fuel, and therefore money

You might be surprised to learn that each individual category of critical component listed above contributes quite a bit towards your engine’s overall fuel consumption. For example:

- Charge air system – up to 2%

- Cylinder unit – up to 1%

- Fuel injection system – up to 1.5%

These numbers might sound small, but when you’re burning thousands of tons of fuel a year, every single drop saved represents money in the bank and lower emissions. When you keep these components well maintained you’re saving your bottom line – including EU ETS costs and possible FuelEU Maritime penalties – and improving your CII rating.

In fact, well-executed maintenance could cut your fuel bill by 50% of the amount spent on an overhaul.

4th benefit – You can reduce emissions, potentially extending your CII compliance by years

The IMO’s CII regulations came into force in January 2023. As it stands, 45% of the merchant fleet risks non-compliance if no action is taken soon. This is why many ship owners and operators are looking for ways to save energy. After all, every drop of fuel saved can help improve their vessel’s CII rating, making it more attractive to potential charterers.

Handpicked related content

Read the article: ”Unsure about CII compliance? Here’s how energy saving technologies can help”. It reveals how energy saving technologies could help you cut emissions by up to 28%!

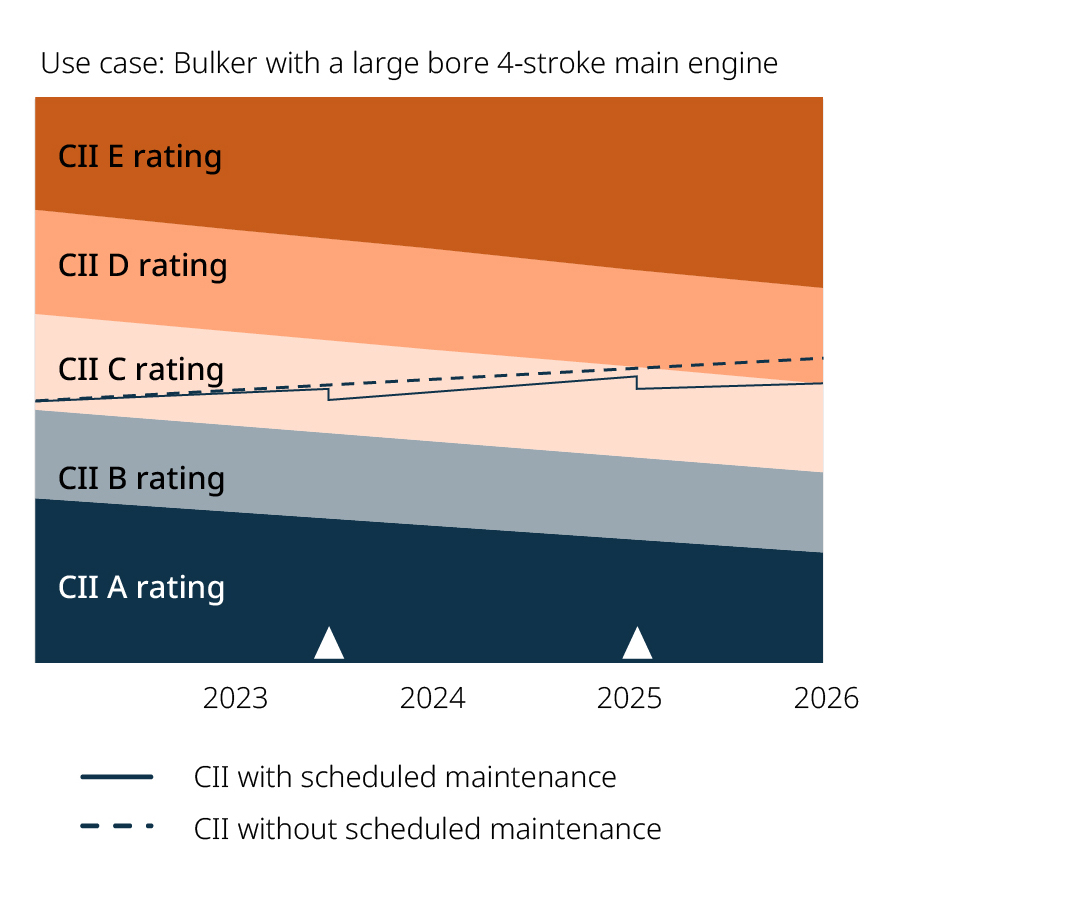

Luckily, a well planned and executed maintenance programme can help keep your vessel compliant for longer – even though the CII regulations will become stricter as time goes on. Here’s a simplified example, which is based on a simulation of a bulker vessel with a large bore 4-stroke main engine.

Each case is unique, but the example shows that:

- with proper maintenance the vessel remains compliant into 2026 and potentially even longer

- without proper maintenance the vessel could require a corrective action plan by 2025

- the choices you make regarding maintenance can have a significant long-term impact on your OPEX.

Want to learn more about how good maintenance practices can save you money and support CII compliance? Watch the Planning maintenance in a changing environment webinar.

Your next smart step

If you have maintenance coming up, planning is the lowest-risk choice. It will help you get the right parts and the right skills to the right place at the right time, minimising the risk of costly delays and budget overruns.

Learn more – download this white paper: “Ship maintenance: 5 strong reasons why you really need to plan it”.

Or subscribe to this newsletter: "Expert tips for reliable ship operations". You will get practical tips for keeping your ship operating reliably while saving money.

Related solutions

Did you like this? Subscribe to Insights updates!

Once every six weeks, you will get the top picks – the latest and the greatest pieces – from this Insights channel by email.