Wind-assisted propulsion for ships: 8 helpful things every ship owner should know

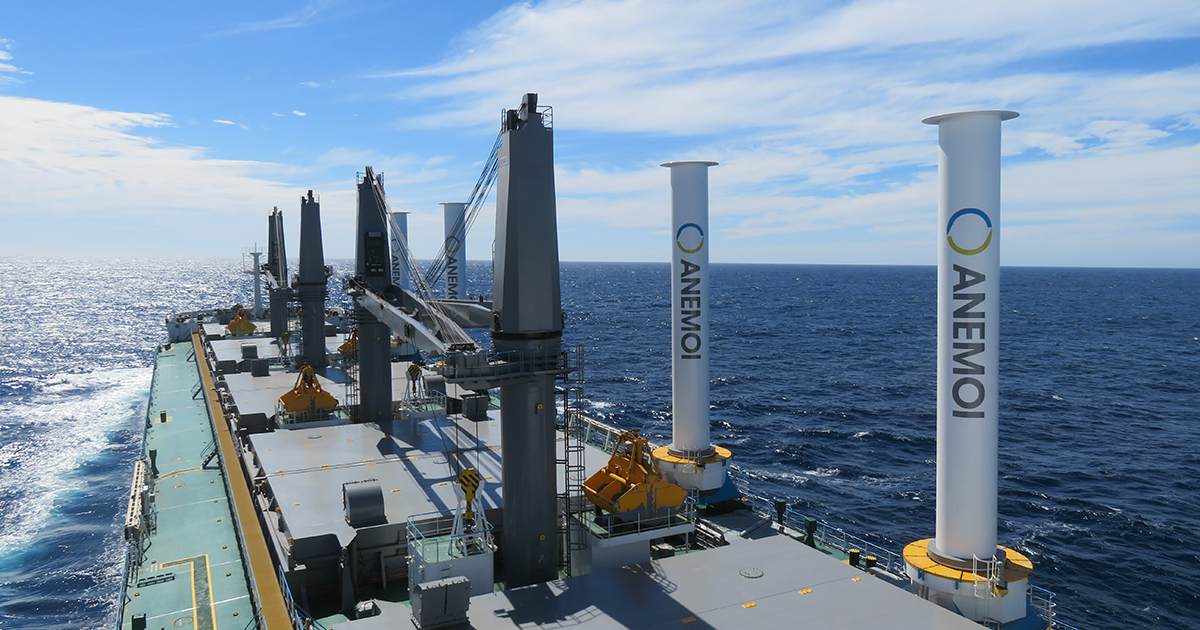

Wind-assisted propulsion for ships has huge potential benefits for ship owners. Using a technology like the Anemoi Marine Technologies rotor sail system available from Wärtsilä can reduce the load on main engines and lower greenhouse gas emissions and fuel consumption by as much as 30%. What are the eight things you should know about wind-assisted propulsion for ships?

In a hurry? Here are the four key takeaways

Wind-assisted propulsion systems (WAPS) harness a limitless source of zero-carbon energy and can be used on almost any type of ship.

- The Anemoi Marine Technologies rotor sail system available from Wärtsilä automatically optimises performance based on wind conditions and uses minimal electrical power.

- WAPS can reduce a ship’s fuel consumption by as much as 30%.

- Wind-assisted propulsion can help improve a ship’s Carbon Intensity Indicator (CII) rating and reduce the cost of complying with regulations like FuelEU Maritime.

- Wind-assisted propulsion for ships can be combined with other technologies to maximise the cost savings and efficiency gains.

How does wind-assisted propulsion for ships work?

Wind has been used as a free and endless source of energy for ships since the first sailboats were invented over 5,000 years ago. Although wind-assisted propulsion has advanced a lot since then, the principles remain the same: wind energy is captured using a device on the ship’s deck to generate aerodynamic thrust. This aerodynamic thrust helps to push the ship through the water.

In the past the device was a sail made from a material like hemp or cotton. Modern wind-assisted propulsion systems are made from a wide variety of materials and come in many different shapes and sizes.

The effectiveness of a wind-assisted propulsion system is measured using the lift coefficient. The lift coefficient measures how effectively a lifting surface, such as a sail or rotor sail, generates lift force from the wind.

Anemoi Marine Technologies rotor sails combine these age-old principles with cutting-edge technology and expertise to make a particularly effective WAPS with a high lift coefficient.

What are the most common types of wind-assisted propulsion for ships?

The three most common types of modern wind-assisted propulsion systems (WAPS) for ships available today are:

- Rotor sails

- Suction sails

- Wing sails

Rotor sails, such as the Anemoi Marine Technologies system, are cylinders that rotate around their own axis. Rotor sails generate aerodynamic lift through a phenomenon called the Magnus effect. The rotation creates a difference in pressure over the rotor. This pressure difference generates aerodynamic thrust.

The amount of thrust depends on wind angle and wind speed. Rotor sails generate maximum thrust when the wind is blowing perpendicular to the shaft. They do not need to be trimmed against the angle of the wind to maintain the lift coefficient, but they do need a moderate amount of electrical power to operate continuously.

Suction sails are wing or oval shaped. An electric-powered suction system sucks air through a downwind perforated surface. This suction effect increases lift and reduces drag. Suction sails need to be trimmed to the optimum angle of attack to maintain the lift coefficient, and they also need a moderate amount of electrical power to operate the suction system.

Wing sails are aerofoil-shaped devices and often have flaps to increase the lift force they generate. Wing sails can be hard shells, or soft or hybrid devices made of textiles. Like suction sails, wing sails need to be trimmed to the optimum angle of attack to maintain the lift coefficient.

Depending on their height, wing sails may need to be tiltable so that the ship can operate safely in ports, or to prevent damage from high winds. Wing sails need a small amount of electrical power to operate the trimming and folding or tilting mechanisms.

Ships can also use soft sails – the simplest type of wind-assisted propulsion, made from flexible fabric. Kites are another type of wind-assisted propulsion for ships. Kites are sail-like devices that are attached to the deck by ropes and fly high above the ship.

What types of ships can use wind-assisted propulsion?

Wind-assisted propulsion is a viable option for almost any type of ship. If your ship has enough deck space and unobstructed airflow, it could benefit from installing one or more rotor sails.

Particularly good candidates include:

- bulkers

- tankers

- RoRo vessels

- pure car and truck carriers, PCTCs

- LNG carriers

You can retrofit a ship with a wind-assisted propulsion system even if the ship wasn’t originally designed to carry one.

The ships that will benefit most from wind-assisted propulsion are those that sail consistent routes over longer distances with lower speed profiles. Consistent routing makes it easier to predict the wind conditions that the ship will encounter on its voyage.

However, ships that operate on shorter routes with favourable wind conditions can also benefit from a WAPS. Wärtsilä can help ship owners assess which vessels and routes are best suited for a WAPS to help maximise efficiency gains. Wärtsilä can also analyse the potential benefits of wind on a vessel’s proposed route during different times of the year.

What are the main benefits of wind-assisted propulsion for ships?

The biggest benefit of wind-assisted propulsion for ships is that it gives you access to an endless and free source of power. This is true whichever technology you choose.

“You can use wind power to lower your ship’s fuel bill and, critically, the amount of greenhouse gas (GHG) emissions your ship generates. Anemoi Marine Technologies rotor sails could lower your ship’s fuel use and GHG emissions by as much as 30%.

However, it is important to remember that the potential savings you can gain with wind-assisted propulsion for ships will depend on five factors:

- The size and displacement of your ship

- The number and size of sails or other devices

- The routes your ship sails

- The type of wind technology

- Your vessel speed

What emissions regulations does wind-assisted propulsion help ships comply with?

Wind-assisted propulsion can have a big impact on your ship’s Carbon Intensity Indicator (CII) rating. The IMO’s CII rating scheme requires owners and operators of vessels above 5,000 GT to submit a rating every year that demonstrates the efficiency of their ships.

A ship’s CII rating is based on the amount of CO2 emitted per unit of cargo-carrying capacity and nautical mile travelled, meaning it is directly determined by fuel consumption. A WAPS can improve your ship’s CII rating by reducing fuel consumption.

Wind-assisted propulsion for ships can also:

- Reduce costs associated with the EU Emissions Trading System. With a WAPS your ship will use less fuel and generate lower emissions. When your ship’s emissions are lower, you will pay less in the form of European Emissions Allowances (EUAs). EUAs are the credits you need to buy to pay for your ship’s emissions.

- Make it easier for you to comply with the FuelEU Maritime Regulation. The FuelEU Maritime regulation defines GHG emission intensity requirements for ships. Wind-assisted propulsion will help you lower the amount of fuel you use, which reduces the GHG emissions from your ship. FuelEU Maritime includes a specific wind reward factor.

What do I need to know if I am considering wind-assisted propulsion for my ship?

If you are considering wind-assisted propulsion for your ship, the things you need to think about will depend on whether you are building a new ship or retrofitting an existing ship.

For newbuilds, wind-assisted propulsion has huge potential. You can design your ship to have a WAPS installed from the start, or design it as a ‘wind-ready’ vessel. A wind-ready vessel is one where all the systems and components are installed so that a WAPS can be added relatively easily and quickly in the future, without drydocking.

If you are designing a newbuild vessel, the most important thing to optimise is the hull. When your ship’s hull is optimised for wind-assisted propulsion you will maximise efficiency gains and cost savings. An optimised hull will reduce the interaction effects between the WAPS and the hull that can negatively affect ship operation and efficiency gains.

You should also consider your ship’s machinery concept – which includes the propulsion system, power generation systems and auxiliary equipment. A ship that has a flexible machinery concept stands to make the biggest gains from using a WAPS.

For retrofits on existing vessels, here is a helpful checklist of seven questions you should think about:

- Does your ship have enough deck space to accommodate a WAPS?

- Is your ship’s structure able to accommodate the additional weight, dynamic forces and components of the WAPS, or will you need to make modifications?

- Does your ship operate on a route that will enable gains from a WAPS?

- Does your ship have any limitations on its maximum vertical height, also known as air draft restrictions? If there are restrictions, you will probably need a WAPS that can tilt or fold.

- How will the WAPS be integrated with your ship’s power and control systems?

- Can you find a slot at a shipyard or other location to perform the installation?

- What are the class certification requirements for the WAPS you are thinking about installing?

Wärtsilä experts can help you determine which technologies will give you maximum gains whether you are designing a newbuild vessel or retrofitting an existing ship.

How can wind-assisted propulsion for ships work together with other technologies?

Wind-assisted propulsion can be combined with other technologies to maximise both the return on investment and the efficiency gains. Here are four examples of technologies that can be used together with a WAPS.

1. WAPS and GATE RUDDER™ by Wärtsilä

GATE RUDDER comprises two foils on either side of the ship’s propeller that can independently rotate their angular position. This rotation changes the hydrodynamic load on both the propeller and the foils. When manoeuvring into, out of and around port, the foils act as a thrust-directing device.

A ship with a WAPS and a conventional rudder will need propeller flow over the rudder to generate rudder forces. GATE RUDDER by Wärtsilä sits in the vessel's speed flow next to the propeller. This means that the GATE RUDDER force remains constant at constant vessel speeds even if the propeller thrust is reduced to accommodate the thrust generated by the WAPS.

2. WAPS and voyage optimisation systems including weather routing

Traditional voyage optimisation systems will typically plan routes that avoid wind and optimise for the calmest weather. But if your ship has a WAPS, you want to take maximum advantage of the wind conditions along your route.

Choosing the right voyage optimisation system makes this possible. You can make smarter routing decisions with a system like Wärtsilä’s Fleet Optimisation Solution (FOS). FOS includes a Voyage Optimiser tool that uses weather data, safety parameters and your efficiency targets to plan the most optimal route for your vessel. The optimal route is the one where your ship’s WAPS can harness favourable wind conditions to lower fuel consumption and greenhouse gas emissions.

3. WAPS and hybrid systems

A hybrid system onboard a ship combines an energy storage system, typically batteries,

with a conventional engine. The battery smooths out power demand peaks, which

eliminates dynamic load on the engine and reduces fuel consumption. Because the engine runs at a steadier load, it can be run safely at higher load factors and has less wear and tear.

With a WAPS you can make an already flexible hybrid-electric system even more flexible. With the extra thrust generated from the wind-assisted propulsion you can reduce the load on the ship’s engine even further. Doing this does not have a negative impact on the efficiency of the electric motor. A hybrid-electric setup can also cope much better than a conventional setup with varying wind conditions.

4. WAPS and propulsion control systems and shaft generators

You can use a propulsion control system like Wärtsilä EcoControl in combination with wind-assisted propulsion. EcoControl is a smart propulsion control system that identifies the most efficient setpoint between the propeller pitch and the engine RPM. These parameters are adjusted automatically in real time to help you gain the maximum benefit from your WAPS.

If the route is planned to help the ship gain maximum benefit from the wind conditions along the way, EcoControl can keep the engine operating as close as possible to its optimal operating point, where it is most fuel efficient.

When you use a WAPS like rotor sails to generate thrust on a ship with a 2-stroke main engine, you can power the rotor sails using a shaft generator in power take-out mode. In most cases using a shaft generator in this way helps to reduce the running hours of the auxiliary gensets, thus reducing the maintenance cost.

5. WAPS and propeller feathering

In some cases a WAPS can enable such a significant power reduction that it becomes feasible to power down one of the ship’s main engines. If the ship has a controllable pitch propeller (CPP), switching off a main engine will create drag.

This drag effect can be eliminated by using the CPP’s feathering capability. In conditions where the WAPS generates more aerodynamic thrust than your ship needs to maintain the desired speed, you can use the CPP to generate electric energy.

Alongside these five approaches, there are other options open to you. These include tuning your vessel’s engine so that it works optimally with WAPS – for vessels with a 2-stroke engine, one option is to implement closed-loop controls between the engine, shaft generator and WAPS.

How can I gain maximum benefit from wind-assisted propulsion?

If you want to gain maximum benefit from wind-assisted propulsion for ships, working with an experienced partner is an excellent starting point.

If you are retrofitting a WAPS to an existing vessel, there are three ways that Wärtsilä Decarbonisation Services can help:

- Analyse – Wärtsilä can gather and analyse ship data from a variety of sources and use it to analyse the current state of your ship.

- Simulate – Experts can use data to build a digital model of your vessel. This virtual model is used to simulate the effects of different combinations of technologies and how they interact with each other.

- Advise – Wärtsilä will give you actionable advice on the right solutions for your needs from both a technical and economic perspective.

If you are building a new vessel, Wärtsilä’s Integrated System Solutions experts can get involved at the start of the design process to help you integrate a WAPS into your overall ship design concept. This kind of expert advice will ensure that your WAPS works seamlessly with all the other systems onboard.

Conclusion

Wind-assisted propulsion for ships has huge potential benefits. A WAPS, such as the Anemoi Marine Technologies rotor sail, gives you access to a limitless supply of emission-free energy that can reduce ship greenhouse gas emissions and fuel consumption by as much as 30%.

You can use this energy to optimise the load on your ship’s engines and reduce fuel consumption. You may also be eligible for financial rewards for installing wind-assisted propulsion. To get the most from wind-assisted propulsion, working with an experienced partner like Wärtsilä is an excellent starting point.

Can you boost your ship’s CII rating and stay competitive at the same time? Energy-saving technologies are part of the answer, and you’ll find 11 clever tips in this quick guide: CII rating: 11 smart ways to boost it while staying competitive.

Written by

Did you like this? Subscribe to Insights updates!

Once every six weeks, you will get the top picks – the latest and the greatest pieces – from this Insights channel by email.