Wärtsilä Marine leads the industry in its journey towards a decarbonised and sustainable future. Our portfolio of engines, propulsion systems, hybrid technology and integrated powertrain systems deliver the reliability, safety, and environmental performance to decarbonise the worlds fleet. We offer our customers performance-based agreements, lifecycle solutions, and an unrivalled global network of maritime expertise.

Articles

Webinars

Whitepapers

Case studies

Rawabi goes hybrid to cut emissions and costs

- Challenge: Reduce emissions and running costs for a key anchor handling tug supply (AHTS) vessel.

- Solution: Wärtsilä hybrid retrofit combining conventional engine gensets and batteries.

- Benefit: Lower emissions, optimal engine operation and reduced operating costs.

Going hybrid with a retrofit for one of its key vessels in the Arabian Gulf has helped Rawabi Vallianz Offshore Services (RVOS) save on emissions and running costs. How does the vessel make the most of its battery-engine combo? Why was hybrid operation a great choice for this regional pioneer? Read on to find out.

The challenge: reduce emissions and running costs

Rawabi Vallianz Offshore Services (RVOS) is an ambitious organisation with the goal to become the leading offshore support services provider in its region. Its new fleet includes the Rawabi 324, an anchor handling tug supply vessel operating in the Arabian Gulf. The vessel takes part in anchor handling, rig-move and platform supply operations as well as firefighting and safety standby tasks. RVOS wanted to cut emissions, reduce fuel consumption and minimise maintenance costs on the vessel, while optimising performance.

The solution: a Wärtsilä hybrid retrofit

To meet these goals, RVOS worked with Wärtsilä to retrofit the Rawabi 324 with a hybrid power system that combines a conventional engine and batteries. Rawabi’s ESG guidelines encourage the company to use environmentally friendly solutions, and hybridisation is a perfect match with this aim. Rawabi chose Wärtsilä because of the company’s experience with hybrid retrofits, as Ahmed AlQadeeb, Vice President, Oilfield Services at Rawabi explains: “Wärtsilä can deliver a solid engineering solution, and we know we can trust the quality.”

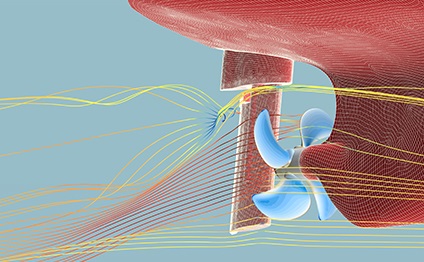

The Wärtsilä hybrid system is designed to optimise the overall operation of the vessel. It cuts fuel consumption and maintenance costs, and significantly reduces exhaust gas emissions.

Because the system combines conventional engine gensets with batteries, it improves the efficiency of the Rawabi 324. The engines can run at an optimal load while batteries absorb load fluctuations. By increasing the power redundancy, the system allows the engine to operate close to its optimum design point, where it has the highest efficiency and lowest emissions.

“Wärtsilä can deliver a solid engineering solution, and we know we can trust the quality.

The RVOS engineering team set performance benchmarks for redundancy and reserve power while the vessel is operating in dynamic positioning mode. Wärtsilä provided the engineering calculations and design options. Once the solution was agreed, work began in a shipyard in the Middle East.

“Both RVOS and Wärtsilä share the same values and a belief in delivering high-quality service. The companies’ motivated teams ensured that the communication went seamlessly throughout the project, from engineering to final product delivery,” explains AlQadeeb.

No project is without its challenges, of course, particularly during the execution phase, which for the Rawabi 324 project meant multiple engineering changes and modifications. “Thanks to the dedicated team, all the challenges faced were overcome smoothly and with an outcome that was beyond satisfactory,” says AlQadeeb.

The benefit: high efficiency with low emissions

The retrofit exceeded Rawabi’s expectations. With fewer engines running at any given time, overall engine running hours onboard the Rawabi 324 are now lower. The engines now also run at the optimum load at all times, reducing operating costs and emissions.

“At Rawabi, we consider ourselves the technology market leaders. Our goal is always to introduce new technologies that will support our performance – maintaining our reputation for safety and efficiency,” says AlQadeeb.

“Overall engine running hours onboard the Rawabi 324 are now lower. The engines now also run at the optimum load at all times, reducing operating costs and emissions.

Supporting Saudi Arabia’s vision for greener shipping

As part of its Vision 2030, the Kingdom of Saudi Arabia is undergoing widespread infrastructural changes to enhance the quality of life and adopt new green technologies. “This project aligns with Saudi Arabia’s vision. It’s a small step that supports the Kingdom’s green initiative, which aims to reduce the country’s emissions and increase its renewable energy capacity,” explains AlQadeeb.

A second vessel, Rawabi 29, is now undergoing the same upgrade, with more retrofits planned thanks to the success of this initial project.

Interested in how going hybrid could help you slash fuel bills and emissions? Take a look at Wärtsilä hybrid solutions.

Want to know how you can optimise your vessel’s performance across its entire lifecycle? Check out Wärtsilä lifecycle upgrades.