There’s more to electric shipping than electric propulsion

Electric shipping and hybrid ships are important solutions now that the marine industry has entered a new era – the age of decarbonisation and strict regulation. Vessels must be future proof: flexible enough to adapt to the changing needs in the future. As the regulation evolves and restrictions on emissions become stricter, the best way to stay competitive is to rely on the best available technologies. Electric shipping or ship electrification is one of the key solutions for marine decarbonisation.

The future of shipping is here: Play the video to discover how these interesting electrical solutions can reduce the environmental footprint for different vessels.

Electrical solutions and decarbonisation

Electrical solutions will deliver reduced emissions as retrofits and offer a competitive advantage also for newbuild vessels.

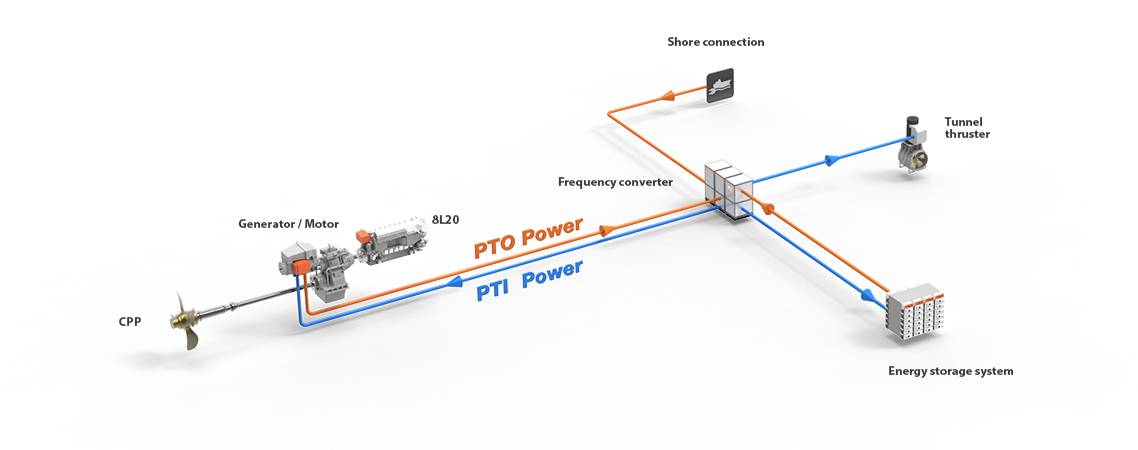

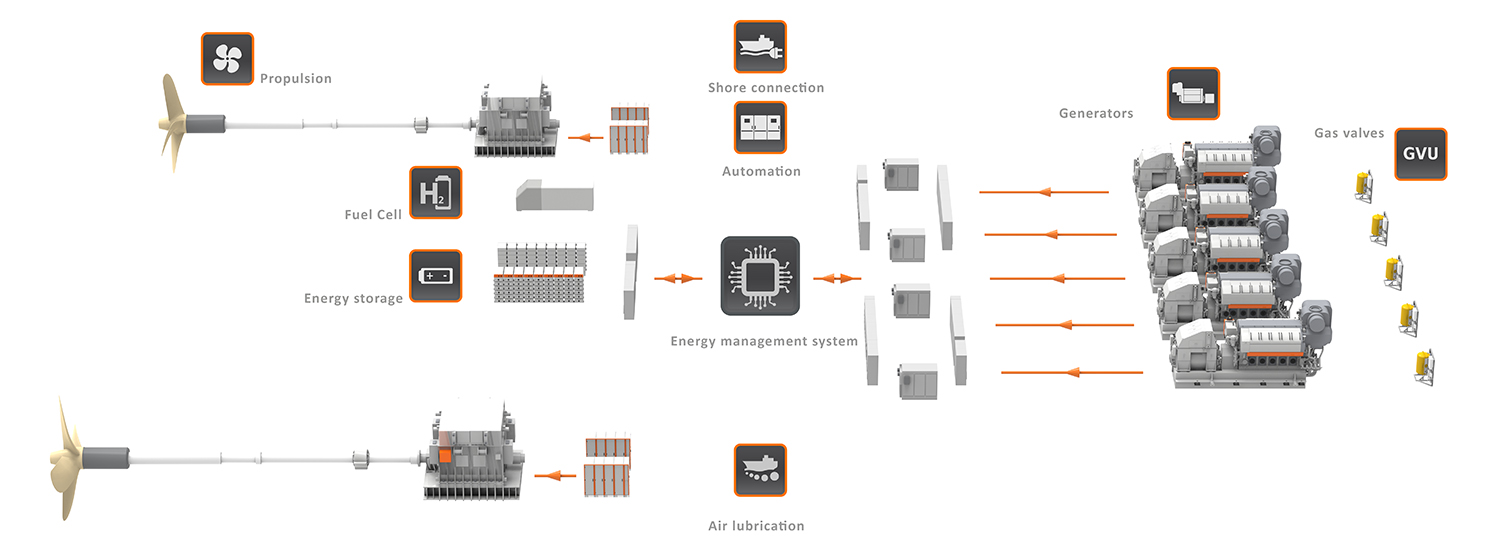

Electrical solutions have been part of vessel design for many years in the form of diesel-electric propulsion or shaft generators, for example. The share of green energy – from renewable sources such as wind, water, and solar – in land-based electrical grids is on the increase.

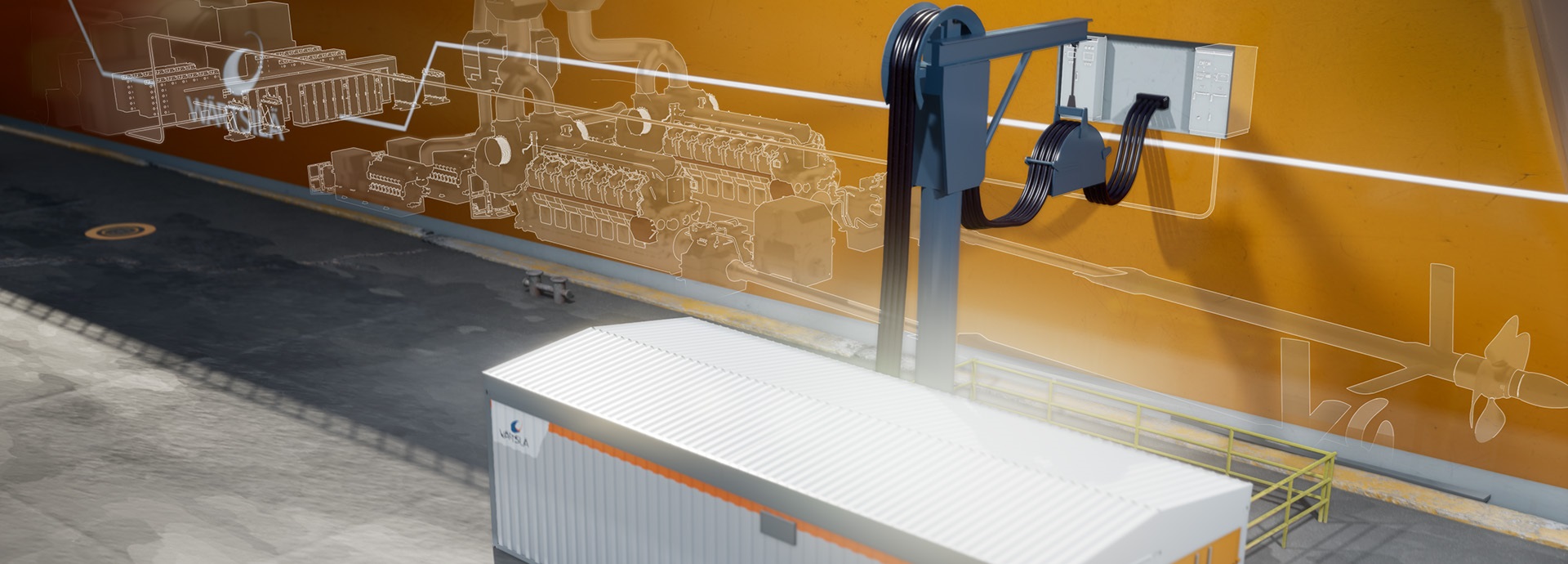

It makes sense for ships to take advantage of shore-based green energy. As an example, using a shore connection can reduce emissions significantly while the ship is in port. Depending on the vessel and its operating profile there are many ways to reduce its emission footprint. The key is optimisation: finding the right solution for each vessel.

Slow steaming used to be the favourite solution for many vessels to reduce emissions. Flexibility was not an issue then, so this means that some vessels will never be fully optimised. Electrical systems onboard make it possible to use smarter propulsion systems. Smarter, more resilient, and more flexible – and thus capable of adapting to the changing needs in the future of shipping.

What powers cruise ships in the future? Will cargo ship engines be electric?

Deepsea vessels will have to adopt green fuel engine technology to decarbonise. Electrical systems will be an integral part of the system including shaft generators and shore connection. Electric cruise ships and electric cargo ships are a futuristic concept, but they can go hybrid and take advantage of solar energy to improve their efficiency.

Tugs can benefit from hybrid or even full electric solutions. They operate close to the shore to land based electrical infrastructure. Because they have high load variations and spend long periods of time on standby, hybrid electric solutions will cut their GHG emissions significantly.

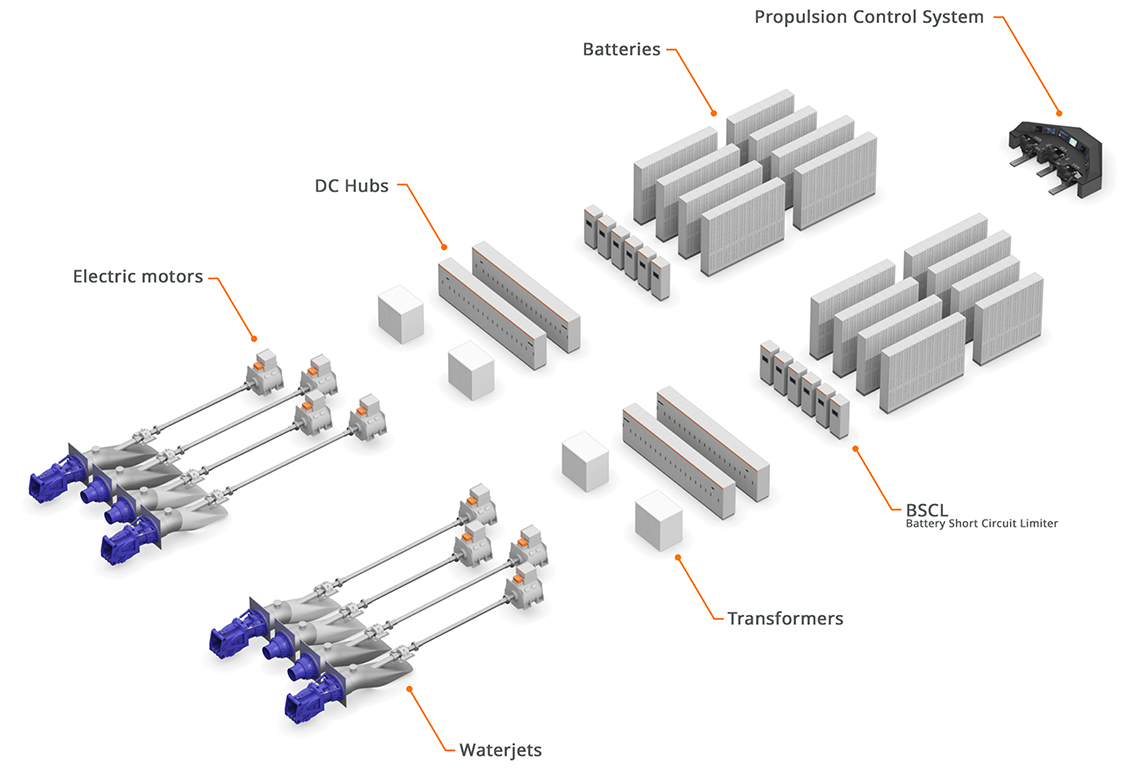

Ferries are often part of local transportation routes and can easily use the land-based charging infrastructure. If the route is short enough, the ferry can even be fully electric. Many ferries still prefer to have a hybrid electric solution to minimise risks.

Any short-distance or coastal vessel can be a hybrid ship. They can charge their ship battery with green energy available at the port. They can be a zero emission ship while manoeuvring, station keeping, and port navigating if they switch to full electric power during those operations.

Could you benefit from a hybrid solution?

Hybrid systems can be used on a wide variety of vessel types, both newbuilds and retrofits. Discover the clever ways that a hybrid solution could help you cut your vessel’s operational costs.

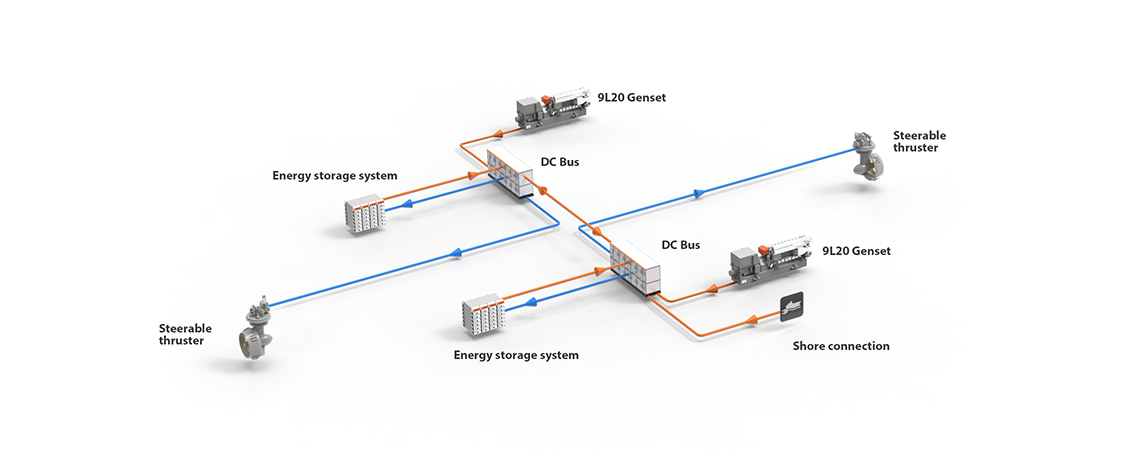

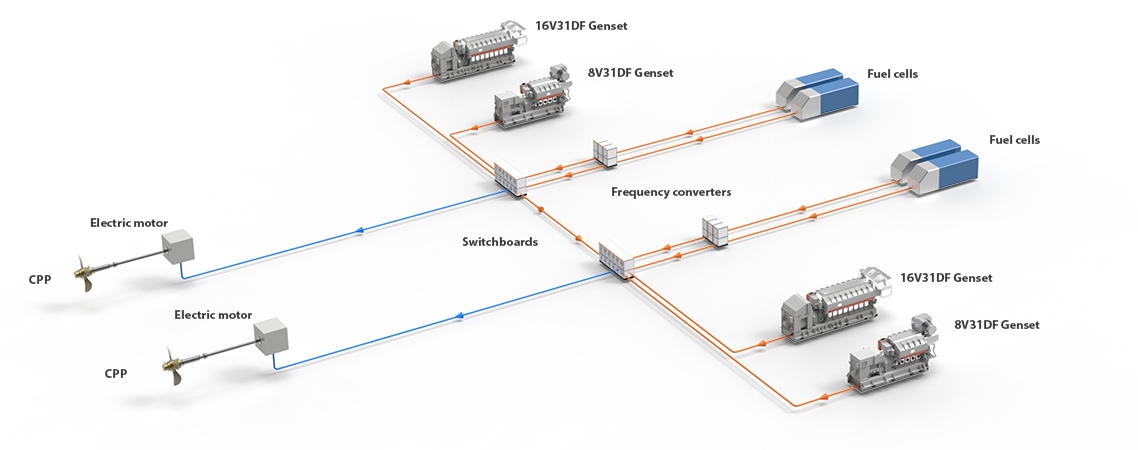

Battery-powered ships, hybrid ships or diesel-electric ships?

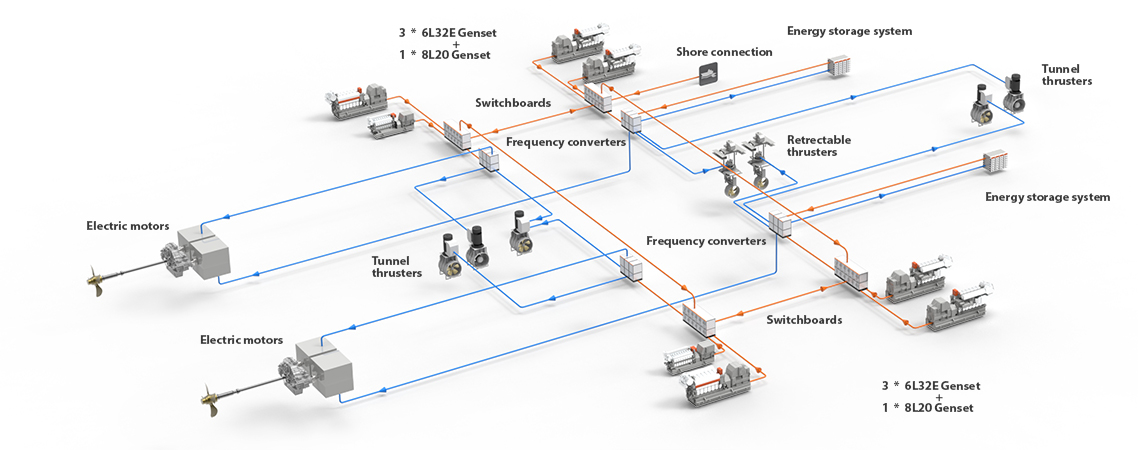

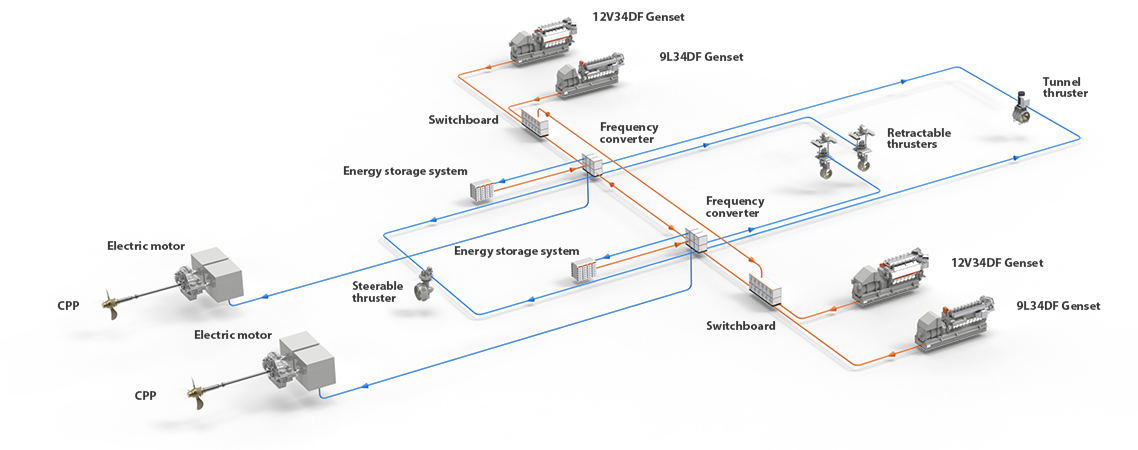

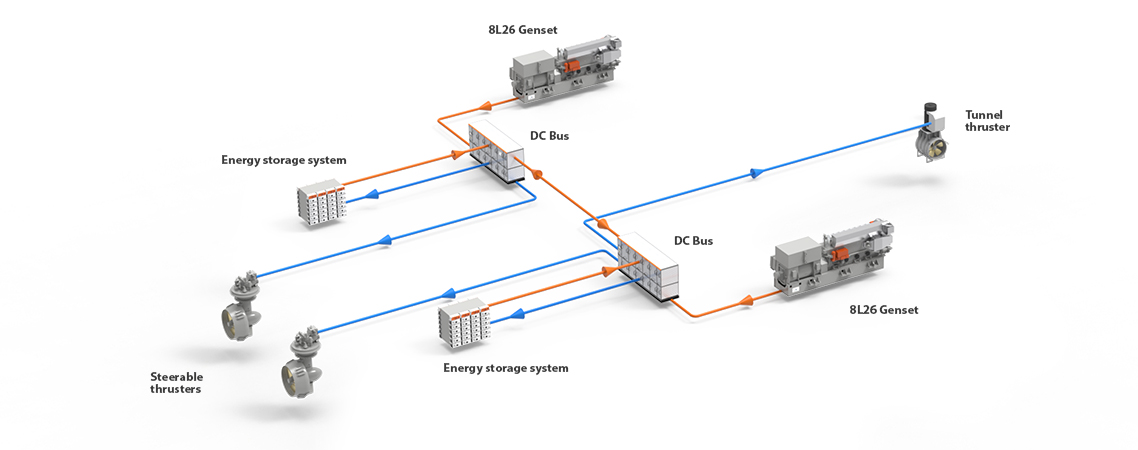

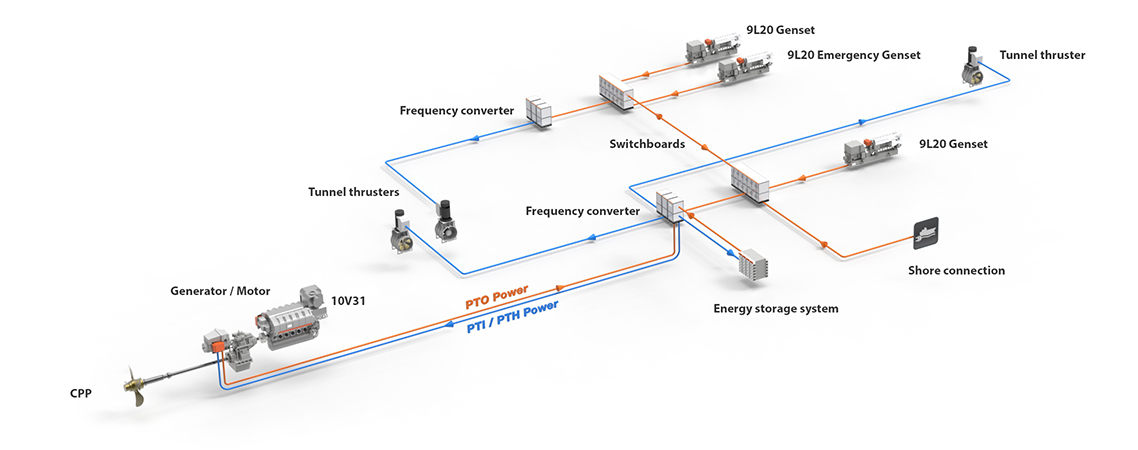

Which solution would be optimal for your vessels? The following are examples of actual solutions.

E&PMS landing page Solutions

Expand all

Why electrification – market trends and drivers

Watch the video and you will also learn three reasons to consider ship electrification as a solution for marine decarbonisation.

Solutions in more detail

Customer stories

Discover the benefits others have already gained from marine electric solutions.

Insights on electric shipping

Discover these insightful articles and case studies – they will build your knowledge of ship electrification and hybrid marine solutions.

Webinars related to electric shipping

Explore what you need to know about electric shipping and hybrid ships: watch the webinar recordings to learn from experts from the maritime industry and associations.

Hand-picked press releases

Take your easiest step on your journey to ship electrification - get in touch and let’s discuss your needs and options!