Electric propulsion system

for ships: flexible and efficient for newbuilds and retrofits

A Wärtsilä electric propulsion system uses electric motors to drive the propeller(s) with power from generator sets, batteries, or a hybrid energy mix. This architecture helps you run generating sets closer to their optimal load, improves redundancy, and enables smooth integration of future energy sources.

The electric propulsion system at a glance

What it is: Electric motors drive the propulsors. Gensets and/or batteries produce the power. An energy management system (EMS) controls the whole.

Why it matters: The electric propulsion system makes it possible to operate the generators within their optimal operational range even when the load from propulsion varies. This will save fuel and cut emissions compared to running engines inefficiently at low load.

Who it’s for:

Newbuilds that appreciate flexibility for future fuels/energy sources and have high hotel load or varying speed (ferries, cruise, offshore, merchant).

Retrofits driven by changing operational needs – including new DP requirements or higher manoeuvring demands – where improved OPEX stability and system flexibility are essential.

The current decarbonisation requirements mean that many more types of vessels are considering to adopt electric propulsion.

Key benefits

Saves fuel.

At lower propeller speeds, the number of generators that are online can be adjusted according to the power demand. The engines will run more efficiently, which saves fuel.

Lower emissions.

The electrical propulsion system can lower emissions even with diesel generators. This is because the electrical propulsion system makes it possible to operate the generators within their optimal operational range even when the load from propulsion varies.

Adopting electrical propulsion for a ship can significantly reduce the emissions of NOx/NO, CO, CO2, and soot.

Low noise and vibration.

Electric propulsion drives are unsurpassed for their quietness of operation. This is important for passenger comfort and research/special‑purpose missions.

Redundancy.

The propulsion system on the ship can be configured for better redundancy. This will makes the system more reliable.

Smoother manoeuvring and positioning.

The electric propulsion system has excellent dynamic characteristics. Changes in propeller speed and propeller reversals during manoeuvring and positioning can be carried out at optimum acceleration rates.

Responds to operational needs.

The torque-speed of the motor makes it possible to high-over torque at propeller standstill. The propeller can be driven at all speeds and torques within design limits – there are no other limitations.

Outstanding mains quality.

The electric propulsion system generates only minimal harmonics or voltage drops, which means that the interference to mains is also minimal.

Easier to operate.

A ship navigation and command system can control the electric propulsion drives automatically, and manually from any control console. The functions and operating states are monitored, which will prevent operating mistakes and overloads.

Leaner installation and OPEX savings.

Choosing an electric propulsion system for a ship instead of a diesel mechanical one means that there are fewer diesel motors and cylinders. The system also allows the motors to operate at constant speed, which reduces wear and tear. The result: lower costs of maintenance and less frequent demand for spare parts, which saves money.

What is an electric propulsion system?

An electric propulsion system separates power production from thrust generation. Gensets and/or batteries provide the power to the converters and motors that drive the propeller(s). This means that the gensets can operate at optimal load more of the time even when the propulsion demand varies. This is more efficient than operating the large engines at low loads.

A hybrid energy storage can buffer peaks and provide spinning reserve.

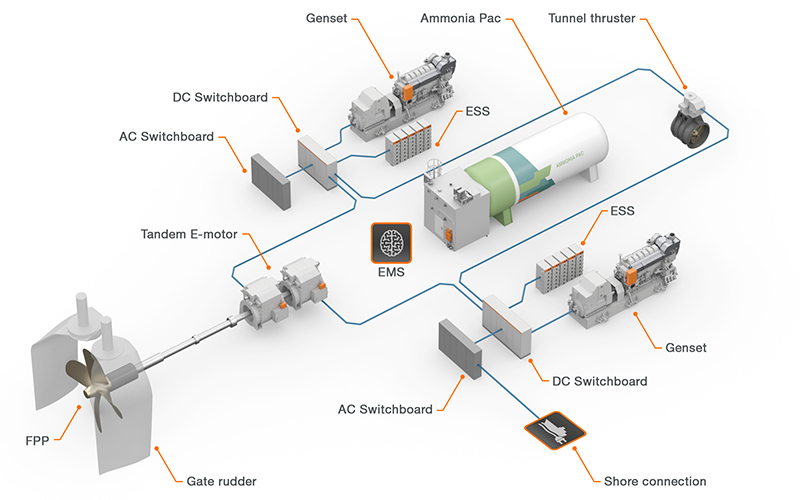

The following is an example configuration of a diesel-electric propulsion system on a vessel:

Why an electric propulsion system from Wärtsilä makes business sense

Electric marine propulsion is a flexible solution, and flexibility will safeguard you from the uncertainty about the availability and cost of sustainable fuels, for example. If you are not sure about the additional power sources that will support your combustion engines, you will need flexibility.

The classical diesel-electric propulsion system is flexible because of one major advantage. The power generating units (gensets) are only electrically connected to the electric propulsion system. This makes it easier to replace the units with a new power source – such as a future-fuel operated engine, a battery, or a fuel cell.

Wärtsilä can provide integrated systems consisting of propulsors and gears, thrusters, controls, energy management, and shore power. This will reduce interface risks.

“Wärtsilä has delivered electric propulsion systems to more than 350 vessels – to tugs, offshore vessels, research and special vessels, and to large cruise ships.

Converter topologies

There are three basic topologies for an electric marine propulsion system: AC system, DC system, and Wärtsilä’s patented Low Loss Solution. Wärtsilä will consider your vessel’s needs and propose the optimal topology, which may be a smart combination of the basic topologies.

AC system

Alternating Current (AC) systems are the most common diesel-electric propulsion solution, in Low Voltage (440 / 690V) or Medium Voltage (6.6 / 11 kV) settings. AC systems combine a switchboard with transformers and AFE (Active Front End) or DFE (Diode Front End) converters for each propulsor.

DC system

The Direct Current (DC) system is gaining popularity. A DC system is always in Low Voltage (1000V) setting. It has the advantage that it can connect variable speed gensets and batteries (which are always DC).

A DC Hub is a combined DC switchboard with converter modules. It is not always smaller or more light weight than the AC equivalent. It is important to weigh the possible advantages of a DC system, especially for a hybrid propulsion system.

Learn more from the article “DC or not DC, that is the question”.

Low Loss Solution

The patented Low Loss Solution from Wärtsilä reduces the number of transformers needed and reduces the electric losses. At the same time, it increases the redundancy of the propulsion system.

With its 200+ installations, the Low Loss Solution is the market standard for DP (Dynamic Positioning) / offshore vessels.

Applications

Electric propulsion for merchant vessels

An electric propulsion system is the ideal choice for owners who feel uncertain about the future of propulsion solutions. The benefits become even more attractive when the vessel will be operating at varying speeds and have a high hotel load. Merchant vessels such as feeders, RoRos, short-sea PCTCs (pure car and truck carriers), and small tankers will gain significant benefits from an electric propulsion system.

Electric propulsion for cruise ships and ferries

Most modern cruise liners and ferries are designed with diesel-electric propulsion systems. These offer numerous advantages in terms of low noise and vibration-free operation, maximized cabin related loading capacity, more economic operation - especially the improved efficiency in partial propulsion power mode, a high degree of reliability, availability and redundancy, lower emission levels, and reduced wear and tear.

Electric propulsion for large LNG carriers

The next‑generation hybrid‑electric LNG carrier design uses compact generating sets to free space for about 9,000 cbm of additional cargo in a standard‑size hull. In real operating profiles, it enables ~10% fuel savings, ~15% lower GHG emissions, and over 20% methane slip reduction compared to current powering solutions. It also provides flexibility and maintains compatibility with existing terminals.

Electric propulsion for offshore vessels

Offshore vessels, pipe and cable laying vessels, and heavy lift jack-up vessels have a long operations time at zero or slow speed and they are often required to change their speed rapidly. Therefore, they need a propulsion system with excellent dynamic characteristics to support their manoeuvring and positioning moves and reversals.

Electric propulsion for special vessels

The ideal propulsion system for special vessels is based on speed-controlled DC or AC motors which drive the propeller either directly or via gears. Research and survey ships and fishery supervision vessels often choose the direct drive option because it is the most reliable and low noise design.

Multi-purpose vessels and icebreakers require propulsion systems with excellent dynamics to permit the flexible use of the torque speed characteristic, up to high-over torques and propeller standstill.

Where an electric propulsion system pays back

What drives ROI

Electric architectures pay back especially when your vessel spends significant time in one of the following:

- at partial load

- manoeuvring or DP

- with high hotel loads.

This is because the gensets can run closer to their optimal load even when the load from propulsion varies. This will save fuel and cut emissions compared to running engines inefficiently at low load.

Shore power can further reduce fuel use in port where infrastructure exists.

Key levers

- Load profile fit: Frequent speed changes, DP or standby periods favour electric/hybrid setups that smooth peaks and avoid low‑load penalties.

- Hybridisation level: Energy storage enables peak shaving and spinning reserve, reducing running hours and improving responsiveness.

- Topology selection: AC hub, DC hub or Wärtsilä’s patented Low Loss Solution can lower electrical losses and increase redundancy, supporting availability and lifecycle cost.

- Compliance context: More efficient engine loading and shore‑power readiness can help support EEXI/CII strategies.

Segment examples

- LNG carriers: A next‑generation hybrid‑electric design indicates ~10% fuel, ~15% GHG and >20% methane‑slip reductions at real trading speeds, with ~9,000 cbm more cargo capacity in a standard‑size hull.

- Short‑sea cargo and ferries: Recent hybrid projects show improved engine loading, redundancy and harbour operations with DC Hub, EMS/EPM and batteries.

Explore the next‑generation hybrid‑electric LNG carrier design and its quantified performance gains.

Retrofit essentials

Feasibility depends on space for switchboards/energy storage, cabling routes, and docking windows. Wärtsilä provides a phased path that helps manage CAPEX and downtime.

Proven results

Examples of vessels with electric propulsion: discover the benefits others have already gained.

Resources

- Read article to discover four successful ways to electrify mechanical propulsion – from basic to brilliant

- Read article to learn 5 exciting reasons why it’s time to invest in ship to shore power

- Download white paper: How to spend less on ship fuel and make amazing savings every sailing

- Read article to learn the surprising reason why hybrid ships are such an excellent idea

- Low Loss Solution: take a look at the low loss concept explainer

Hand-picked press releases

Frequently asked questions

Ready to explore your electric propulsion options?

Get guidance tailored to your vessel and operating profile — from comparing mechanical and electric architectures to identifying the most efficient way forward for your next project.

Parts of this page have been written with the help of AI. A human expert has verified the contents.