Propulsion control systems for smooth operations

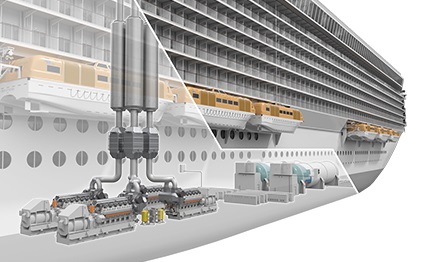

A propulsion control system is an important element of the automation systems on board a ship. An ideal system ensures that the sailing is smooth and efficient. You can save fuel, cut emissions and optimise operations.

Wärtsilä’s Propulsion Control System PCS consists of control devices, displays, indicators and modules, which have been designed to operate with any propulsion configuration on a modern ship.

You will operate the PCS using the ProTouch remote propulsion control system.

Wärtsilä ProTouch remote propulsion control system

Controlling the propulsion systems is easy with the Wärtsilä ProTouch remote propulsion control system. Its lever unit and touchscreen provide an easy-to-use, responsive interface for controlling the vessel’s propulsors. Control is as easy whether there is a single propulsor or several.

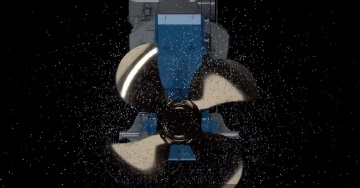

ProTouch lets the operator control multiple propulsors in the system:

- Thrusters – transverse, steerable, and retractable

- Controllable pitch propellers

- Waterjets

- Gate rudders.

ProTouch integrates seamlessly with Wärtsilä propulsors for optimal performance.

Benefits that you will get

- Convenient. ProTouch is the single control point for all units in the propulsion system.

- Easy to use. The user interface in ProTouch is intuitive. All propulsors in the system are visible on a single screen.

- Fit for purpose. ProTouch offers views tailored for the captain sailing the ship and other views for the engineer controlling and monitoring the propulsion equipment and related auxilliaries.

- Reliable. ProTouch uses the latest technology.

For ship builders, ProTouch is an ideal choice because it is easier to install. One ProTouch will be able to control the whole propulsor system, so there are fewer components to install. Its modular design makes installation even easier.

Available: optimal Wärtsilä ProTouch layout for your needs

You will find an optimal Wärtsilä ProTouch layout, matching your vessel and its propulsor types. The following are just a few examples of possible ProTouch layouts.

Wärtsilä ProTouch layout

Expand all

Watch this video to learn more about Wärtsilä thrusters and propulsion controls for heavy-duty dynamic positioning:

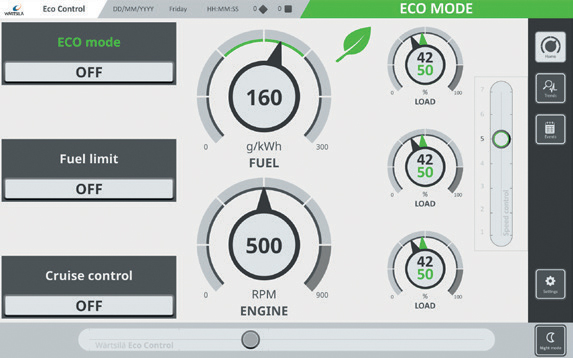

Wärtsilä EcoControl

The Wärtsilä EcoControl is a smart propulsion control system for marine vessels. It will improve the vessel’s efficiency because it uses the most efficient setpoint between propeller pitch and engine RPM, adjusting the parameters automatically and in real time.

A smart propulsion control system will reduce emissions

Be A smart propulsion control system on board a ship can vastly improve the fuel efficiency of your ship during transit sailing. Better fuel efficiency means that you can save fuel – and cut emissions. There are 50 other ways to cut emissions in addition to a smart propulsion control system. You will find all of them in this fascinating eBook: “51 great ways the maritime industry could cut its greenhouse gas emissions”. Learn more:

Propulsion solutions

Wärtsilä’s propulsion control systems can manage all the components in the propulsion product portfolio – thrusters, controllable pitch propellers, waterjets, and gate rudder. Learn more about the propulsion solutions in the portfolio:

Propulsion control services

Because the lifecycle of electrical and electronic components is becoming shorter, Wärtsilä has developed a lifecycle roadmap for the propulsion control systems. This roadmap helps ensure that the lifecycle of the propulsion control systems is at least 15 years.

After 15 years, the customer will have the option to purchase a replacement control system with equivalent or customised functionality.

Customer cases

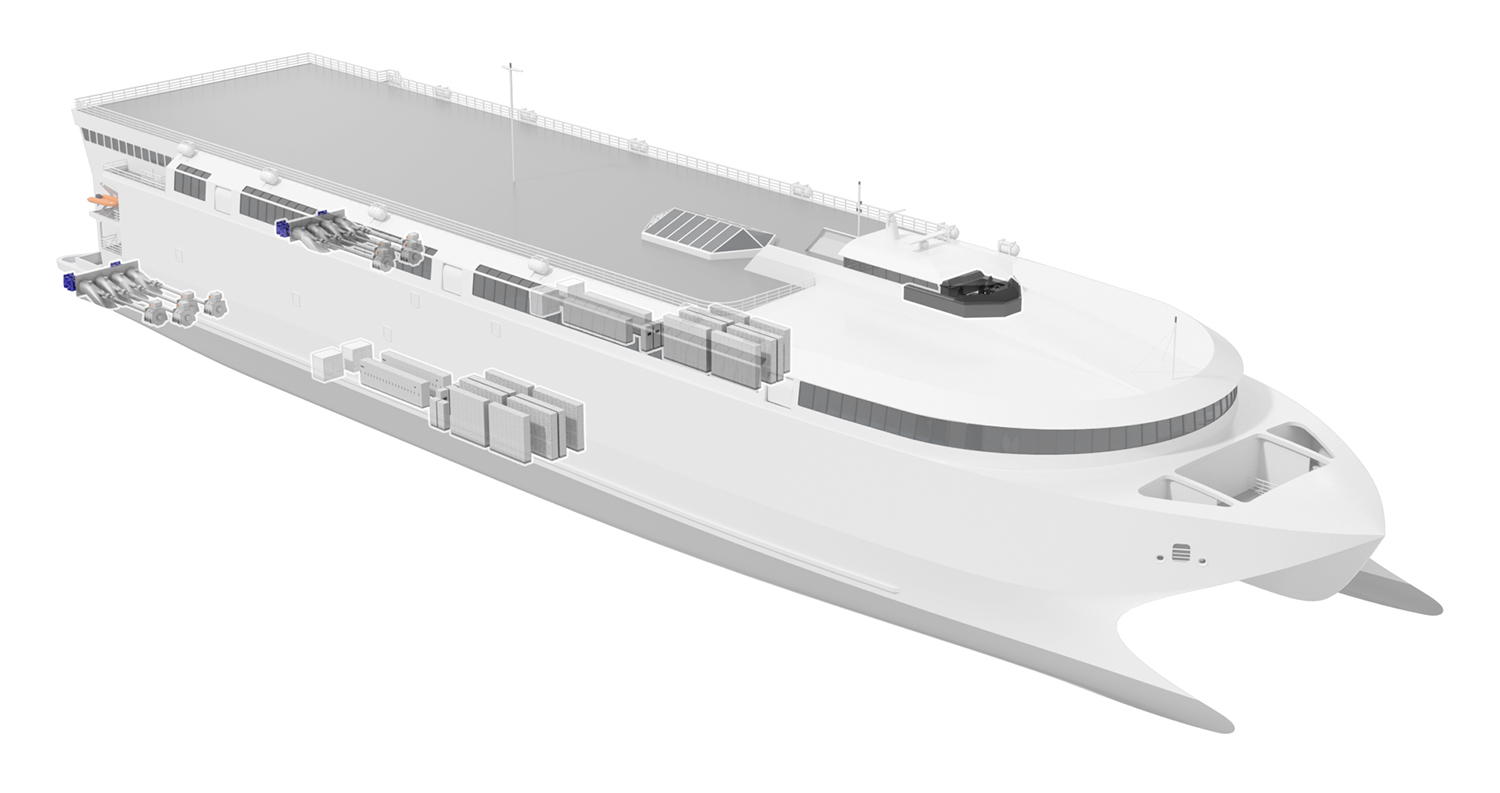

Case Incat Tasmania. Electric ships powered by batteries are becoming more and more interesting for companies who want to be more sustainable. One interesting example is a new ferry being built by Incat Tasmania, ordered by Buquebús. The new ferry will be fitted with the ProTouch remote propulsion control system.

Discover the benefits others have already gained from propulsion control solutions.

Hand-picked press releases

Insights on propulsion

Discover these insightful articles – an easy way for you to build your knowledge of propulsion solutions.

Revolutionise your propulsion control and experience the power of Wärtsilä’s propulsion control systems. Contact us today to learn how ProTouch can benefit your operations.