Wärtsilä Marine leads the industry in its journey towards a decarbonised and sustainable future. Our portfolio of engines, propulsion systems, hybrid technology and integrated powertrain systems deliver the reliability, safety, and environmental performance to decarbonise the worlds fleet. We offer our customers performance-based agreements, lifecycle solutions, and an unrivalled global network of maritime expertise.

Articles

Webinars

Whitepapers

Case studies

What did Wasaline do to improve fuel efficiency and reduce emissions?

A view from the bridge – fuel optimisation

Using your engines and systems more efficiently is the fastest route to more sustainable and economical vessel operations. Technical Director Jonas Teir reveals how Finnish ferry operator Wasaline is taking big strides forward in fuel efficiency with engine upgrades and data monitoring.

Wasaline’s state-of-the-art Aurora Botnia is a 150-metre-long RoPax vessel with 1,500 lane metres of cargo and vehicle space plus room for 800 passengers. Launched in August 2021 it’s one of the world’s most efficient and sustainable ships – already compliant with the IMO’s 2050 greenhouse gas reduction target and the EU’s upcoming Fit for 55 package.

So what is Wasaline doing to improve fuel efficiency and reduce emissions on what is already a highly efficient vessel?

“Fuel optimisation is the fastest route to more sustainable and economical vessel operations,” says Teir. Our ambitious environmental targets and the current spike in fuel prices make fuel efficiency a critical part of daily operations for us.”

These are the four ways Wasaline is improving fuel efficiency and reducing emissions.

1. Upgrading engines

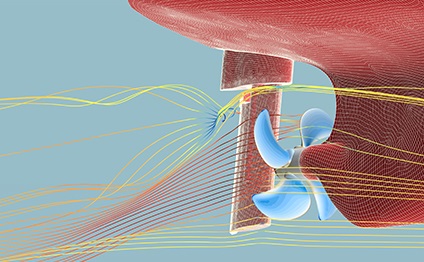

“While saving a few per cent in annual fuel consumption per year might sound small, on a larger scale it has a huge impact. We are able to use the vessel as an R&D test platform and technology demonstrator, and the learnings from this project will benefit other ferry operators too,” says Nico Höglund, Product Manager, Wärtsilä 31 engine.

“After just a few years Wasaline could see double-digit reductions in fuel consumption compared to where they started. This translates into an equivalent reduction in emissions, or perhaps even more. From a wider perspective, looking at the whole supply chain there are energy savings from well to tank.”

2. Using hybrid propulsion

The Aurora Botnia’s hybrid propulsion solution combines engines and 2.2-MWh batteries. In theory the Aurora Botnia’s could operate solely on batteries, but in practice these are mostly used for peak shaving and as spinning reserve to optimise engine operation. The batteries are also used to provide power for manoeuvring in port and to power the vessel’s hotel load.

The outlook so far is very promising, with data showing that operating with batteries has contributed to a three to four percent improvement in fuel economy.

“We are still taking baby steps with the hybrid system, so this is a learning curve for us,” Teir points out. “Wärtsilä’s monitoring and guidance has been crucial in this respect because it has allowed us to confirm or ignore our hunches and ideas about how to make optimal use of the system. The data gathered helps us to see the real impact of operating with batteries and to see how we can do things better.”

The outlook so far is very promising, with data showing that operating with batteries has contributed to a three to four percent improvement in fuel economy.

3. Optimising maintenance based on real engine data

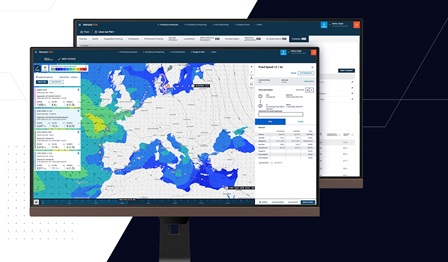

The main Wärtsilä equipment and systems aboard the Aurora Botnia are covered by a 10-year Wärtsilä Optimised Maintenance agreement. Under the agreement Wasaline benefits from predictive maintenance support using cutting-edge digital solutions based on artificial intelligence.

We can use the collected data and Wärtsilä’s expertise to fine tune the engines for even better reliability and fuel economy.

“Proper engine maintenance is one of the cornerstones of good fuel efficiency,” Teir points out. “Data monitoring and analysis is a huge part of helping us achieve this. This goes beyond the ‘nuts and bolts’ of a traditional maintenance agreement because the engine parameters are monitored continuously. We can use the collected data and Wärtsilä’s expertise to fine tune the engines for even better reliability and fuel economy.”

4. Using flexible dual-fuel technology

The Aurora Botnia’s four Wärtsilä 31DF dual-fuel engines can burn liquefied natural gas (LNG) and/or biogas. Wärtsilä LNGPac™ technology is used for LNG storage, supply control and monitoring. This dual-fuel capability helps Wasaline avoid the problem of having all its eggs in one basket in terms of fuel – both now and in the future. “With our current setup we have multiple alternatives to choose from,” says Teir.

“On top of fossil LNG and diesel the vessel can also operate on biodiesel, liquefied biogas (LBG) and, when they become available, eFuels like eDiesel and synthetic LNG. This makes us more resilient to situations like the current challenges with LNG availability. It also means we have multiple pathways to decarbonise with low and zero-carbon fuels.”

“For me, the future is not full of endless challenges but limitless opportunities. Our collaboration with Wärtsilä is a chance to learn from each other and do something significant in the field of fuel efficiency that will benefit not just us, but the entire ferry industry,” Teir concludes.