Wärtsilä Marine leads the industry in its journey towards a decarbonised and sustainable future. Our portfolio of engines, propulsion systems, hybrid technology and integrated powertrain systems deliver the reliability, safety, and environmental performance to decarbonise the worlds fleet. We offer our customers performance-based agreements, lifecycle solutions, and an unrivalled global network of maritime expertise.

Articles

Webinars

Whitepapers

Case studies

Hybrid upgrade cuts Maersk Minder’s fuel consumption

As well as increasingly strict environmental regulations, offshore vessel operators are also facing growing pressure from their customers to cut emissions. A Wärtsilä HY hybrid upgrade for the Maersk Minder, an anchor handling tug supply vessel operated by Maersk Supply Service, has reduced its fuel consumption and carbon emissions as well as reducing maintenance needs and improving operational performance. The upgrade is the first of its kind for this type of vessel.

In the often harsh and unforgiving world of offshore maritime operations, safety and reliability are naturally top of the priority list for vessel operators. But with emissions regulations becoming increasingly tight and fuel costs spiking, a third priority has joined them – fuel efficiency.

With this in mind, Maersk Supply Service selected the Wärtsilä HY hybrid battery upgrade for its Maersk Minder anchor handling tug supply (AHTS) vessel. The company is a leading provider of marine services and project solutions for the offshore energy sector. It operates a large fleet of anchor handling and subsea support vessels, specialising in towing, mooring and installing floating units.

The world’s first hybrid-electric anchor handler

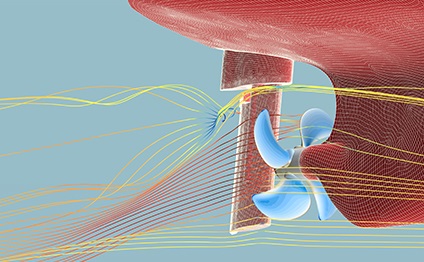

The Maersk Minder is a state-of-the-art DP2 deep water vessel built for anchor handling and offshore operations. It is powered by five medium-speed engines with total output of more than 23,000 horsepower.

“Maersk Supply Service is taking an active role in decarbonising the offshore support vessel sector. This requires both behavioural changes in the way we operate our vessels as well as technological upgrades to our fleet. With this new hybrid battery solution upgrade, we take a significant step forward in our path to further reduce the emissions from our diesel-electric vessels. The use of hybrid batteries/energy storage systems has proven to be an effective solution within the platform supply vessel (PSV) sector; however, we believe that we are on the leading edge in terms of bringing this technology into the AHTS segment. To the best of our knowledge, this will be the world’s first AHTS hybrid battery conversion,” says Mark Handin, COO of Maersk Supply Service.

Charging ahead on battery power

The Wärtsilä HY solution improves vessel efficiency by allowing the engine to run at optimal load, using batteries for peak shaving to absorb load fluctuations. By increasing the power redundancy, the system allows the engine to operate closer to its optimum design point, where it has the highest efficiency and lowest emissions. This also reduces maintenance needs and increases system performance.

Wärtsilä HY provides the reliability and flexibility needed in offshore operations, while also offering reduced fuel consumption, especially in dynamic positioning operations. The extended time between overhauls helps to increase vessel uptime, another key priority in offshore operations.

The upgrade was performed in spring 2022 at the Fitjar Mekaniske Verksted shipyard in Norway. The hybrid setup comprises a 2,000 kW energy storage system with 132 batteries and a transformer, which is controlled and monitored via an energy management system (EMS). The EMS is what differentiates Wärtsilä HY compared to a traditional hybrid system. It is the ’brains’ that ensures all the elements work seamlessly together, ensuring that the energy flow is optimised to achieve the best performance in all operational modes.

In parallel with the hybrid upgrade, Wärtsilä also delivered a selective catalytic reduction (SCR) after-treatment system – the Wärtsilä NOx Reducer (NOR) – and performed an engine upgrade to ensure optimal operation with the after-treatment system. The Wärtsilä NOR reduces the Maersk Minder’s NOx emissions by an average of 80%. It works by mixing a urea solution with the exhaust fumes, creating a reaction that removes the NOx from the flue gas stream.

“The NOR means that the Maersk Minder is already in line with the International Maritime Organisation’s Tier III emissions standards, even though they are only recommended for vessels built after 2021,” says Kenneth Bang, Senior Service Account Manager, Offshore Oil & Gas at Wärtsilä.

Sailing towards a successful, sustainable future

Following the upgrade the Maersk Minder took to the sea in June 2022 for six days of rigorous sea trials off the coast of Bergen in Norway. During this testing, Wärtsilä experts were on board to fine tune the hybrid system.

“The project is a world first for this type of vessel,” Bang highlights. “It reflects Maersk Supply Service’s commitment to being a decarbonisation pioneer in the offshore industry. The steps they have taken with this upgrade are a great example of what can be achieved with the right technologies and an experienced partner.”

Read more about Wärtsilä HY hybrid solutions

Challenge

Reduce fuel consumption and emissions for a state-of-the-art AHTS vessel.

Solution

Wärtsilä HY hybrid upgrade with batteries, plus Wärtsilä NOR SCR exhaust gas treatment system.

Benefit

Fuel consumption and emissions cut with savings verified by the customer; NOx emissions cut by an average of 80%.