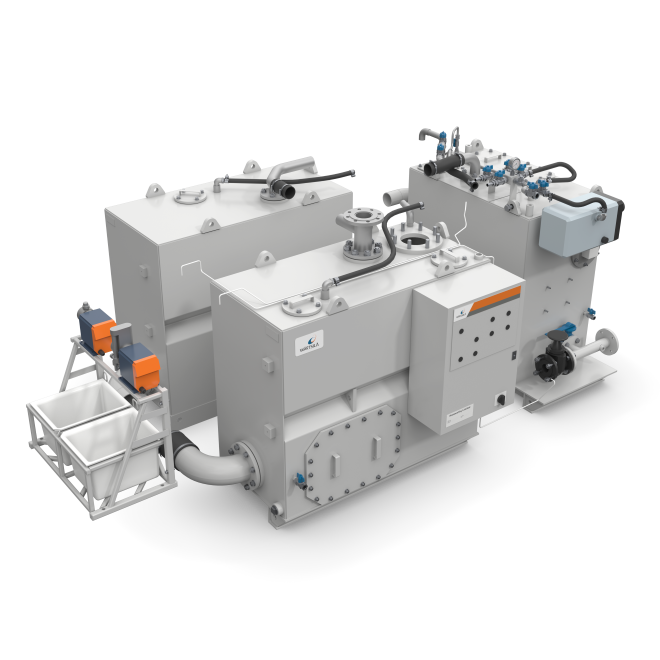

When upgrading or retrofitting your engine room, the RTC retrofit sewage treatment plants are the most convenient solution available to the marine world today. A 3-piece modular design allows for extremely easy installation. The RTC retrofit sewage treatment plants can easily be boarded through standard vessel access ways thanks to their modular design. Three separate modules with limited dimensions prevent the need for hull penetration.

Widely regarded as standard specification by many of the world’s shipowners, the Super Trident® RTC retrofit sewage treatment plants form the most cost effective and safe answer to disposal of wastewater at sea.

The plant ensures compliance to IMO legislation – MEPC.227(64). Minimum maintenance is required.

KEY BENEFITS

MODELS

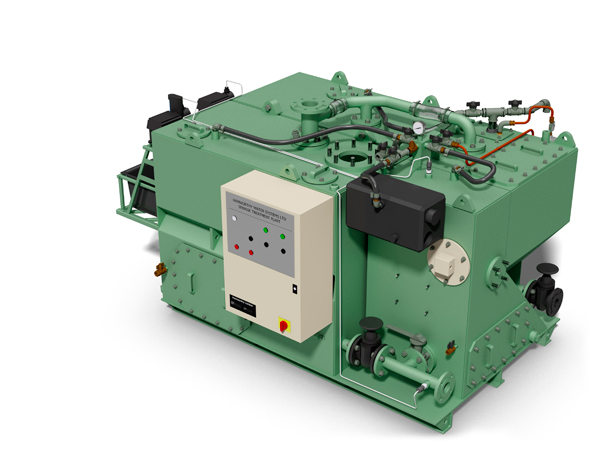

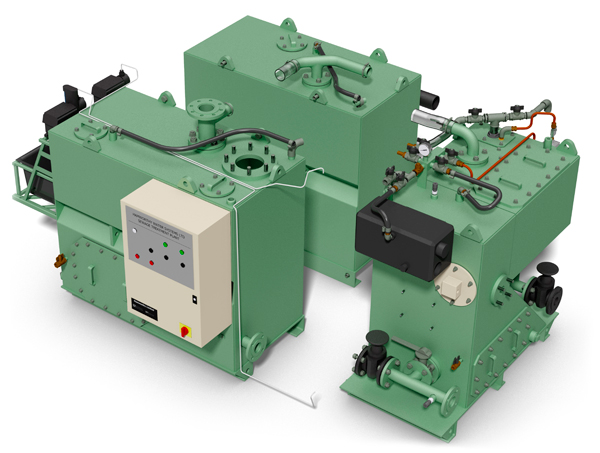

Different models of retrofit STPs

Each size in the retrofit range is built up from three separate water tight tanks connected by external piping, aiding installation. The dimensions of each component has been arranged to permit its transportation through standard vessel access ways.

The dimensions below indicate the size of aperture through which the unit will pass with tanks separated when the control panel, transfer tubes and studs, dosing skid, vent tubes, flow meter and covers are also removed.

| System | IMO certified (litres/day) | Weight full (kg) | Dimensions when assembled (LxWxH, mm) |

|---|---|---|---|

| RTC20-14 | 3120 | 3335 | 2320x1678x1398 |

| RTC40-14 | 6010 | 5340 | 2520x1835x1847 |

| RTC60-14 | 9360 | 7690 | 3010x2035x1937 |

| RTC80-14 | 11840 | 9440 | 3460x3324x2037 |

| System | Aperture width (needed for boarding, mm) | Aperture length (needed for boarding, mm) |

|---|---|---|

| RTC20-14 | 655 | 1220 |

| RTC40-14 | 730 | 1670 |

| RTC60-14 | 830 | 1770 |

| RTC80-14 | 880 | 1870 |

SCOPE OF SUPPLY

As standard

Optional

The retrofit range has been specifically designed to reduce the cost of installing sewage treatment equipment into existing vessels.

Each size in the retrofit range is built up from three separate water tight tanks connected by external piping, aiding installation. The dimensions of each component has been arranged to permit its transportation through standard vessel access ways.

Assembled unit

Separated unit

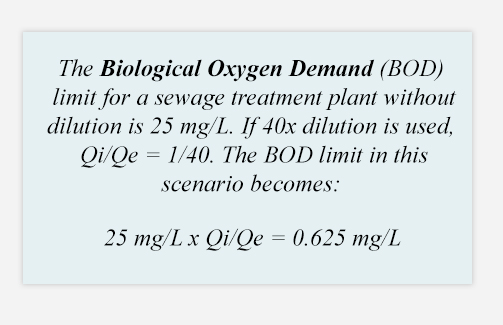

Sewage Treatment Plants installed on or after 1st January 2016 are required to meet the new IMO Annex IV, MEPC 227(64) effluent quality standards, which introduce a Dilution Compensation Factor into the sampling requirements.

Dilution should not be the solution to pollution. IMO intended to tackle ‘dilution machines’ by the introduction of Dilution Compensation Factor (Qi/Qe) in MEPC.227(64). If the volume of the effluent is higher than the volume of the influent due to the use of dilution, the quality of the effluent must be improved by the same factor. Installing an STP that relies solely on dilution will leave ship operators with some difficult questions to answer, even if the STP is type approved. Therefore, for STPs where Qi/Qe <1, it is important that Qi and Qe can be measured and visible.

Please fill in the form, we aim to respond within 1-2 business days depending on the enquiry. For an existing installation, provide all necessary details to identify the installation and the equipment. Fields indicated with an asterisk (*) are required.

For NEWBUILD & RETROFITS, please contact +44 1202 662 600 or waw.sales@wartsila.com

For spare parts, please e-mail us with the Equipment Serial Number or the name of the vessel at pse@wartsila.com. For urgent support, contact +44 1202 662 634.

For technical support & service, please email us with the Equipment Serial Number or the name of the vessel at poole.service@wartsila.com. For urgent support, contact +44 1202 662 616.

Equipment Serial Number is taken from the equipment nameplate and includes all letters and numbers as given on the equipment nameplate.