Sewage treatment plants (STPs) from Wärtsilä are the most cost-effective and safe answer for every ship or offshore platform to dispose of wastewater at sea. No tempering with the quality of our oceans.

Wärtsilä sewage treatment units - also known as 'Wartsila Hamworthy Super Trident' - are certified to meet IMO MEPC 227(64) guidelines. These have been in place for all new-build ships from 1 January 2016 onward.

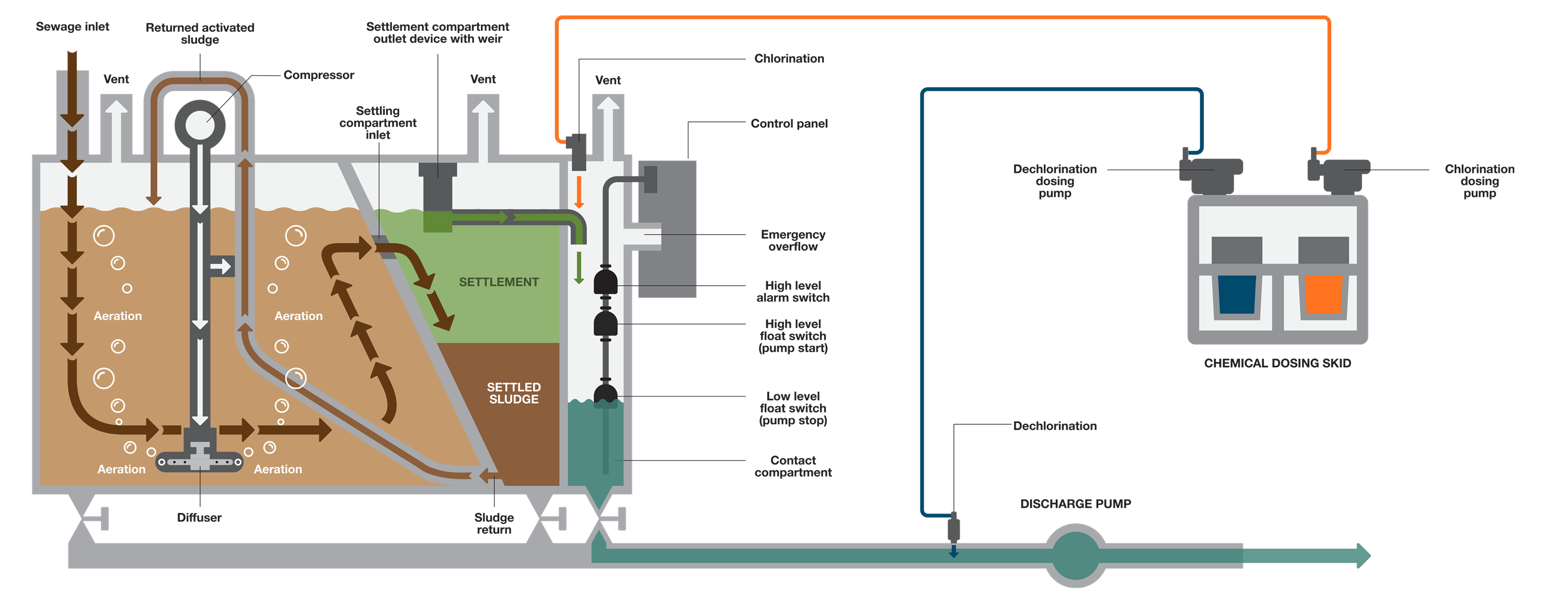

Each Super Trident sewage treatment unit has been optimised to process all onboard black and grey wastewater streams. The plants are compatible with both conventional gravity and vacuum fed collection systems. On top of that, each STP is fully automatic, allowing for unattended operation. This greatly reduces maintenance requirements and lower long-term operating costs.

Finally, Wärtsilä sewage treatment plants for ships are compact and modular in design, suitable for between-deck installations and adaptable to customer new-build specifications.

KEY BENEFITS

FEATURES

MODELS

| System | IMO certified (litres/day) | Dimensions (LxWxH in mm) | Weight full (kg) | ||

|---|---|---|---|---|---|

| STC0-23 | 1030 | 1780 | 937 | 1254 | 1100 |

| System | IMO certified (litres/day) |

Dimensions (LxWxH in mm) |

Weight full (kg) |

||

|---|---|---|---|---|---|

| STC-01-13 | 1740 | 1890 | 1400 | 1181 | 1550 |

| STC-02-13 | 3120 | 2518 | 1863 | 1336 | 3030 |

| STC-03-13 | 4660 | 2622 | 1863 | 1681 | 3959 |

| STC-04-13 | 6010 | 2722 | 2080 | 1821 | 5027 |

| STC-06-13 | 9360 | 3072 | 2280 | 1971 | 7367 |

| System | IMO certified (litres/day) |

Dimensions (LxWxH in mm) |

Weight full (kg) |

||

|---|---|---|---|---|---|

| STC-08-14 | 11840 | 3000 | 2670 | 2000 | 9294 |

| STC-10-14 | 15810 | 3400 | 2750 | 2000 | 11314 |

| STC-13-14 | 20830 | 4400 | 2750 | 2000 | 15036 |

| STC-15-14 | 25704 | 3700 | 3215 | 2300 | 17836 |

| STC-20-14 | 33974 | 4620 | 3215 | 2300 | 22422 |

| STC-25-14 | 40778 | 4620 | 3490 | 2500 | 27446 |

| STC-30-14 | 47422 | 5012 | 3470 | 2700 | 30898 |

| STC-40-14 | 64150 | 6012 | 3915 | 2680 | 43614 |

| STC-50-14 | 80182 | 7000 | 4145 | 2900 | 55526 |

| STC-60-14 | 100800 | 7000 | 4180 | 3500 | 69754 |

SCOPE OF SUPPLY

Please fill in the form, we aim to respond within 1-2 business days depending on the enquiry. For an existing installation, provide all necessary details to identify the installation and the equipment. Fields indicated with an asterisk (*) are required.

For NEWBUILD & RETROFITS, please contact +44 1202 662 600 or waw.sales@wartsila.com

For spare parts, please e-mail us with the Equipment Serial Number or the name of the vessel at pse@wartsila.com. For urgent support, contact +44 1202 662 634.

For technical support & service, please email us with the Equipment Serial Number or the name of the vessel at poole.service@wartsila.com. For urgent support, contact +44 1202 662 616.

Equipment Serial Number is taken from the equipment nameplate and includes all letters and numbers as given on the equipment nameplate.