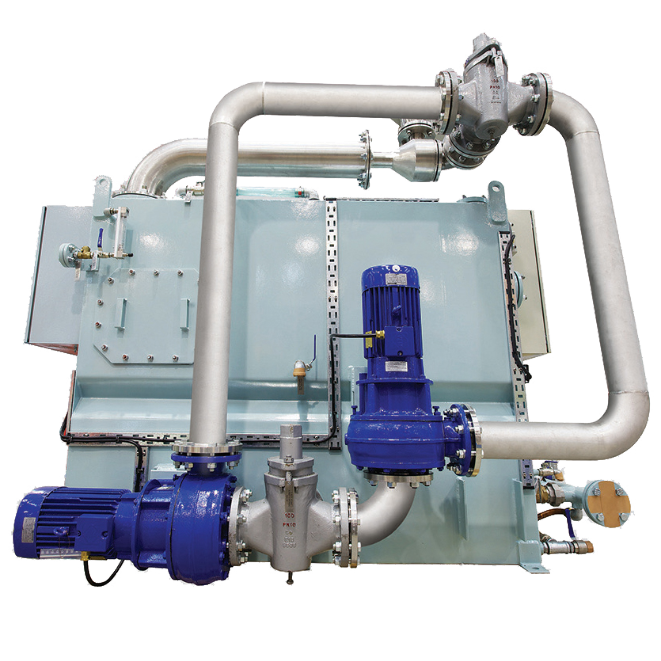

The vacuum collection systems from Wärtsilä Water & Waste use differential air pressure to transport sewage from the toilet bowls, and other sanitary fittings, to the Sewage Treatment Plant (STP) or independent collection tank.

Ejectors can be mounted direct to the STP for modular construction without the need for a separate collection tank, and only a small amount of flush water is needed compared to conventional gravity systems.

KEY BENEFITS

FEATURES

OPTIONS

Please fill in the form, we aim to respond within 1-2 business days depending on the enquiry. For an existing installation, provide all necessary details to identify the installation and the equipment. Fields indicated with an asterisk (*) are required.

For NEWBUILD & RETROFITS, please contact +44 1202 662 600 or waw.sales@wartsila.com

For spare parts, please e-mail us with the Equipment Serial Number or the name of the vessel at pse@wartsila.com. For urgent support, contact +44 1202 662 634.

For technical support & service, please email us with the Equipment Serial Number or the name of the vessel at poole.service@wartsila.com. For urgent support, contact +44 1202 662 616.

Equipment Serial Number is taken from the equipment nameplate and includes all letters and numbers as given on the equipment nameplate.