Wärtsilä's Reverse Osmosis freshwater makers for ships and offshore platforms are able to produce between 20 and 1000 tons of permeate per day. They feature a modular and flexible design that is customizable to meet operational and space requirements of any vessel. Installation and optimization of a reverse osmosis solution on each vessel type and platform is now possible.

Reverse Osmosis (RO) is a water purification technology that uses membranes to remove salts and impurities from seawater in order to create permeate (freshwater). Wärtsilä RO plants use semi-permeable membranes: porous sheet barriers that blocks the flow of salts and other solutes. Seawater is forced through microscopic pores in the membrane under pressure, while larger dissolved solids and heavy molecular weight contaminants are flushed away as reject water.

KEY BENEFITS

TECHNICAL DATA

WORKING PRINCIPLE

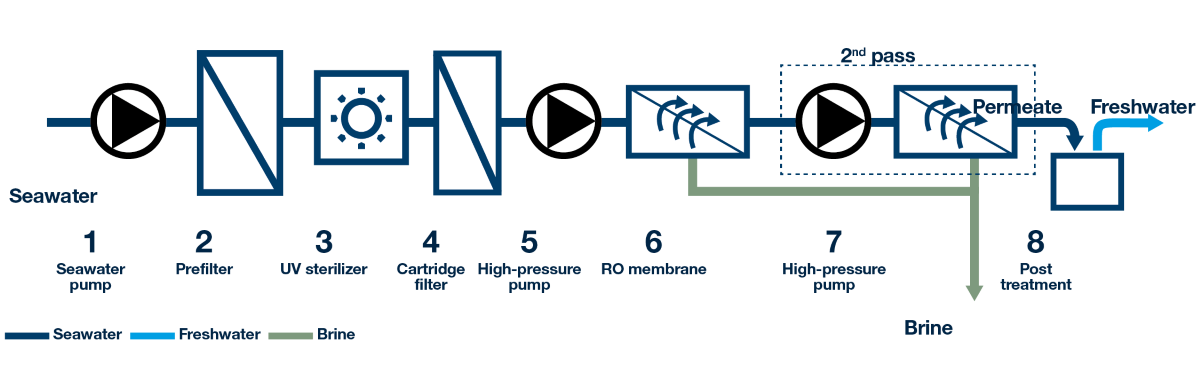

Seawater is pumped into the RO system by a seawater pump (1). Incoming water is subjected to double filtration. In the first prefilter stage (2) the seawater is filtered from all suspended solids up to 40-50 micron for large RO plants, and 5 microns for small standard plants. A second prefilter stage (4) further filters the water down to 5 microns for large RO plants, and 1 micron for small standard plants. In large RO plants a UV reactor (3) is installed between the two filtration stages to disinfect the filtered water and avoid bacterial growth on the RO membranes.

The filtered seawater is then pumped through the RO membranes by a high-pressure pump (5). Semi-permeable RO membranes (6) remove ions, particles, and bacteria from seawater to generate permeate/freshwater. The permeate leaves the membranes, while the brine is diverted for discharge. Optional post-treatment (8) consists of pH correction, re-hardening and remineralisation. Large RO plants offer automatic flushing with low salinity water to remove the salty water from the RO housing.

RO plants typically have a single or a double pass configuration. In double pass plants the treated water passes through the membranes twice. The permeate from the first pass becomes the feed water for the second membrane-pass via another high-pressure pump (7). Single pass RO plants typically supply freshwater under 500 ppm total dissolved solids (TDS). When high quality water with a TDS under 20 ppm is required (for example in boilers), a double pass RO plant is necessary.

SCOPE OF SUPPLY

Delivered as standard

Options

Options for large RO plants

Reverse Osmosis plants give Wärtsilä full fresh water generator offering

Please fill in the form, we aim to respond within 1-2 business days depending on the enquiry. For an existing installation, provide all necessary details to identify the installation and the equipment. Fields indicated with an asterisk (*) are required.

For NEWBUILD, please contact +49 4152 805-0 or waw.sales@wartsila.com.

For SPARE PARTS, please e-mail us with the Equipment Serial Number or the name of the vessel at wsc.aftersales@wartsila.com. For urgent support, contact +49 4152 805-130.

For TECHNICAL SUPPORT & SERVICE, please email us with the Equipment Serial Number or the name of the vessel at wsc.aftersales@wartsila.com. For urgent support, contact +49 4152 805-226.

Equipment Serial Number is taken from the equipment nameplate and includes all letters and numbers as given on the equipment nameplate.