With the aid of Wärtsilä's Advanced Oily Water Separators all environmental aspects regarding bilge water issues are easily handled. A minimum impact for the operation staff is guaranteed. And the results easily surpass the legislative requirements for both today and tomorrow. The Wärtsilä Advanced OWS series are IMO and US Coast Guard approved. They give the operator effective control over all bilge media as well as over any discharges made into the sea.

The oily water separating system guarantees a maximum oil content in the effluent of 5 or 15 ppm (parts per million) . Actual results depend on specification, with real case levels being below 1 ppm during continuous operation. The units are designed to conform to the highest safety standards. This makes doesn't only make the advanced OWS units extremely competitive, but it also offers ship owners and operators a substantial value in itself. No accident, discharge or injury should be caused by our equipment!

KEY BENEFITS

Unsurpassed treatment quality

The mixture of fuel oils, lubricants, detergents, solvents and water on board often creates stable emulsions in the bilge water tanks. Without modern and effective bilge water cleaning equipment this may lead to discharges of bilge water containing oil and hazardous components at sea or to unnecessarily high amounts of waste being pumped ashore. The heart of the Wärtsilä range of oily water separators is a groundbreaking separating process which effectively sorts out oil traces even from complicated emulsions. Together with the Solidpac add-on, the units can reduce the amount of bilge water for disposal ashore with as much as 95 percent, enabling substantial net savings in disposal costs.

OPERATION

Safe & secure operation

Safety is another key aspect of bilge water treatment. With older treatment units, an operator normally had to stand watch in order to secure the treatment operation. The Wärtsilä OWS series range from Wärtsilä obviates the need of this as it constantly evaluates the effluent and its own operation parameters. When the treatment quality decreases or routine or unplanned maintenance is needed, a warning is shown on the operator console on the unit and on the optional control screen on the bridge or in the control room. The operator is then guided through the actual corrective actions, all in order to ease and speed up the way back to full operation.

SERVICE

Service & support

Wärtsilä Water & Waste supports its customers throughout the lifecycle of their installations by optimizing efficiency and performance. We offer expertise, proximity and responsiveness for all our customers in the most environmentally sound way.

Our Services & Support solutions range from basic support, installation and commissioning, performance optimization, upgrades and conversions to service projects and agreements focusing on overall equipment performance and asset management. We deliver aftersales support through our network of service centres worldwide.

SCOPE OF SUPPLY

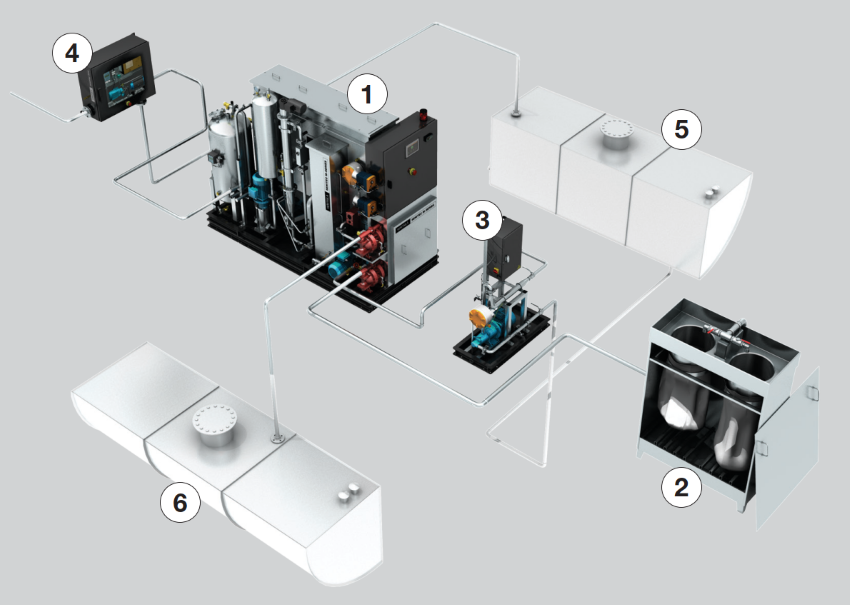

Complete Wärtsilä Oily Water Treatment System

1. Wärtsilä OWS oily water separator

2. Solidpac solids dewatering unit (optional)

3. Onsys pre-system (compulsory on OWS 500 and OWS 2500)

4. Wärtsilä BWG bilge discharge monitoring system (optional)

Not included in the scope of supply

5. Bilge tank

6. Sludge tank

MODELS

| System | Max capacity (m3/h) |

Max capacity (gpm) |

Power (kW) |

Dry weight (kg) |

Wet weight (kg) |

L x W x H (mm) |

Footprint (m3) |

Max. oil in effluent (ppm) |

|---|---|---|---|---|---|---|---|---|

| OWS 500 | 0,5 | 2,2 | 3 | 510 | 800 | 1185x765x1715 | 6,64 | 5 ppm / 15 ppm* |

| OWS 1000 | 1 | 4,4 | 3 | 650 | 1950 | 2344x1100x1855 | 14,47 | 5 ppm / 15 ppm* |

| OWS 2500 | 2,5 | 11,0 | 3 | 950 | 2700 | 3210x1400x1855 | 11,94 | 5 ppm / 15 ppm* |

| OWS 5000 | 5 | 22,0 | 6 | 1000 | 2200 | 2440x1100x2365 | 14,0 | 5 ppm / 15 ppm* |

Environmental issues are a growing concern for companies involved in shipping as well as for governments and global organisations. Although shipping is already one of the most environmentally friendly modes of transportation of goods and people, more and more focus is put on minimizing different types of effluents into air and water. Legislative actions already in operation or coming in the near future also focus on keeping the seas clean.

Please fill in the form, we aim to respond within 1-2 business days depending on the enquiry. For an existing installation, provide all necessary details to identify the installation and the equipment. Fields indicated with an asterisk (*) are required.

For NEWBUILD & RETROFITS, please contact +44 1202 662 600 or waw.sales@wartsila.com

For spare parts, please e-mail us with the Equipment Serial Number or the name of the vessel at pse@wartsila.com. For urgent support, contact +44 1202 662 634.

For technical support & service, please email us with the Equipment Serial Number or the name of the vessel at poole.service@wartsila.com. For urgent support, contact +44 1202 662 616.

Equipment Serial Number is taken from the equipment nameplate and includes all letters and numbers as given on the equipment nameplate.