Reverse osmosis freshwater makers

Reverse osmosis (RO) freshwater makers are technical solutions that convert seawater, well or effluent (polluted industrial water) into freshwater or 'permeate'. Reverse osmosis freshwater makers use membranes to remove salts and impurities from seawater. The semi-permeable membranes are porous sheet barriers that block the flow of salts and other solutes. Feedwater is forced through microscopic pores in the membrane under pressure, while larger dissolved solids and heavy molecular weight contaminants are flushed away as reject water.

After additional miniralisation the permeate can be used as potable water for human consumption or as irrigation water, in the agricultural sector.

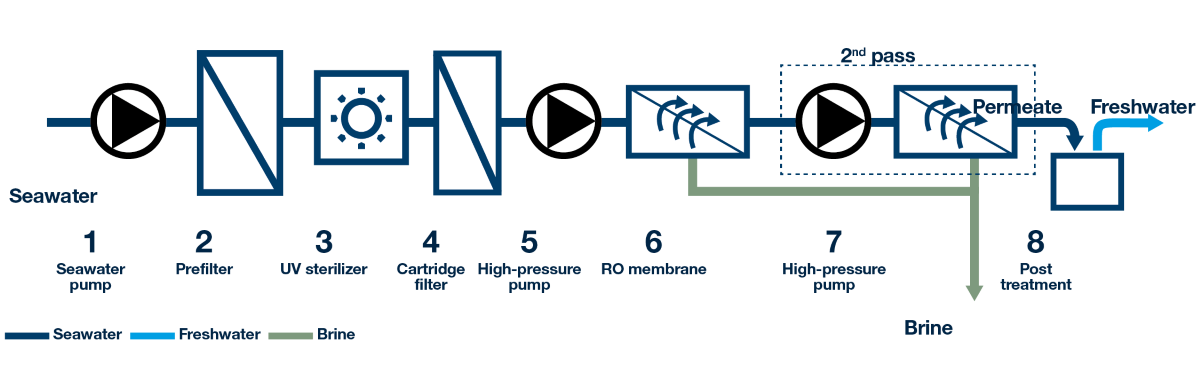

RO freshwater makers typically have a single or a double pass configuration. In case of double pass plants the treated water passes through the membranes twice. When high quality water with a total dissolved solids (TDS) under 20 ppm is required (e.g. for technical water), double pass RO plants are necessary. Discover reverse osmosis freshwater makers from Wärtsilä.

Detailed process description of RO freshwater makers

Seawater (or other feedwater) is pumped into the RO system by means of a pump (1). Incoming water is subjected to double filtration. In a first prefilter stage (2) the incoming water is filtered from all suspended solids up to 5 microns. A second prefilter stage (4) further filters the water down to +/- 1 micron. In some reverse osmosis plants, a UV reactor (3) is installed between the two filtration stages to disinfect the filtered water and avoid bacterial growth on the membranes.

The filtered feedwater is then pumped through the RO membranes by a high-pressure pump (5). Semi-permeable RO membranes (6) remove ions, particles, and bacteria from the feedwater to generate freshwater, aka ‘permeate’. The permeate leaves the membranes, while the brine is diverted for discharge. Optional post-treatment (8) consists of pH correction, re-hardening and remineralisation.

Double-pass solution

The permeate from the first pass becomes the feedwater for the second membrane pass via another high-pressure pump (7). Single pass RO plants typically supply freshwater under 500 ppm total dissolved solids (TDS). Double pass freshwater makers take the TDS under 20 ppm.

Related: Evaporator type of Freshwater Generators / Distillers