Ferry propulsion systems, ferry engines, and more

Ferry operators face increasing pressure to meet emission regulations while staying competitive. Wärtsilä helps ferry companies overcome this challenge with advanced propulsion systems, fuel-flexible engines, and lifecycle services tailored to RoPax, RoRo, high-speed, and electric-hybrid ferries.

Summary: Wärtsilä for ferries

- Trusted by leading operators like Viking Line and Wasaline

- Solutions for newbuilds, retrofits, and lifecycle optimisation

- Technologies for hybrid, methanol, LNG, shore power, and more

- Lifecycle agreements and predictive maintenance

- Proven decarbonisation and compliance support

Balancing compliance and daily operational challenges

How does Wärtsilä help ferry operators stay compliant and reliable — even when daily challenges get in the way?

Whether you are planning a newbuild or upgrading an existing vessel, Wärtsilä offers integrated solutions that support compliance, operational reliability, and long-term efficiency. Our offering spans propulsion systems, engine technologies, and digital solutions — all backed by global expertise and proven results.

Vessel types served include:

- Large and medium sized RoPax/RoRo ferries

- High-speed ferries

- Commuter and short-distance ferries

Three ways ferries can decarbonise

Wärtsilä promotes a three-level approach to the maritime decarbonisation journey:

- Make operations more efficient. Use energy-saving technologies, upgrade engines, and optimise systems.

- Adopt alternative energy sources. Choose engines compatible with LNG, bio-LNG, methanol, and adopt hybrid solutions and shore power.

- Clean up emissions. Install scrubbers, WESPs, SCR systems, and explore carbon capture solutions.

Here’s a more detailed list of actions that the ferry industry can take to drive decarbonisation.

Making operations more efficient

Existing ferries can benefit from a variety of solutions that help improve the efficiency of operations. For example:

- Energy-saving technologies (ESTs)

- Upgrades and repowering for 4-stroke engines

- Solutions for 2-stroke engines

- Converter and switchboard upgrades

- Shaft generator upgrades

- Hybrid solutions and upgrades

Optimisation solutions and services

Adopting and using alternative energy sources

New ferries must prepare for the future and choose engine technology which runs or has the capability to run on alternative fuels. Existing ferries may need to consider fuel conversions.

- Engine technology, capable to run on alternative fuels such as

- LNG and bio-LNG, which are increasingly popular choices for ferries

- Methanol - Hybrid and full-electric solutions

- Shore power solutions and upgrades

Cleaning up emissions

If a ship cannot run on alternative fuels, the smart choice is to clean up emissions.

- Exhaust Gas Cleaning (EGC) or scrubbers acting on SOx

- Wet Electro-Static Precipitators (WESPs) acting on particulate emissions

- Exhaust Gas Recycling (EGR) or Selective Catalytic Reduction (SCR) acting on NOx

- Onboard Carbon Capture Solutions (CCS) acting on CO2

Explore Wärtsilä’s complete ferry propulsion systems and engines for every vessel type.

Solutions for newbuild ferries

Newbuild highlights

- Fuel-flexible engines for future-proofing

- Hybrid-electric solutions for ferries on urban routes

- Shore power solutions

- Energy-saving technologies for better ferry efficiency

- Advanced digital solutions for optimising ferry operations

- Resources and support for ship designers

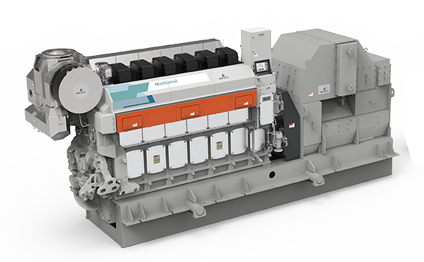

Three popular, fuel-flexible ferry engines

Explore the whole range of Wärtsilä engines: all have been designed for easy maintenance and to offer low lifecycle cost. They are ready for hybrid solutions and easy to upgrade to run on alternative fuels.

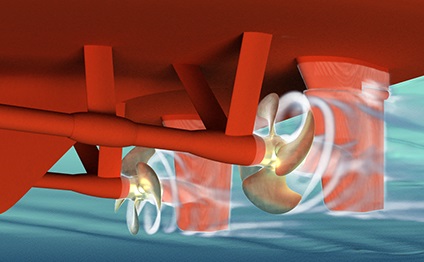

Discover integrated ferry propulsion systems

An integrated propulsion solution is efficient because its parts are carefully optimised to work together: from the rudder, propeller, shaft, seals, gearbox, engines and auxiliary systems to energy saving technologies.

An integrated propulsion system will deliver compliance, reliability, and strategic decarbonisation.

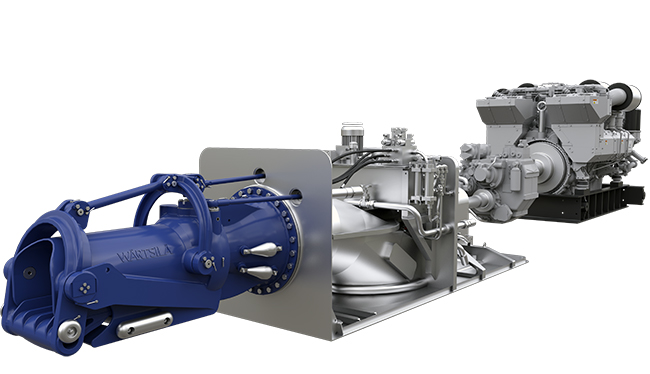

Waterjets for newbuilds

Wärtsilä offers medium-size and modular waterjets suitable for high-speed ferries. The portfolio features units from 500 kW at the low end of the scale up to units with around 10 MW for large RoPax fast ferries.

Fuel systems

Advisory and integration services

Expert support for system integration, compliance planning, and future-proofing your investment. With us, you will find it easier to navigate compliance requirements.

Choose a future-proof investment

- Fuel efficiency, operational efficiency, emissions compliance, and lifecycle cost control

- Fuel flexibility and digital readiness

- Integration of propulsion, energy, and automation systems: designed to work optimally together

Upgrade and retrofit options for ferries

When you are looking for lifecycle upgrades that will improve your vessel’s propulsion efficiency, start with modelling. Modelling is an excellent starting point because it provides a basis for evaluating your options. Consult Decarbonisation Services, and you will have facts and information that help identify the optimal solutions and technologies.

Benefits from upgrades and retrofits

- Cut emissions and fuel costs

- Comply with IMO and regional rules

- Extend vessel life and improve performance

- Wärtsilä supports phased upgrades and integration

Fuel conversions

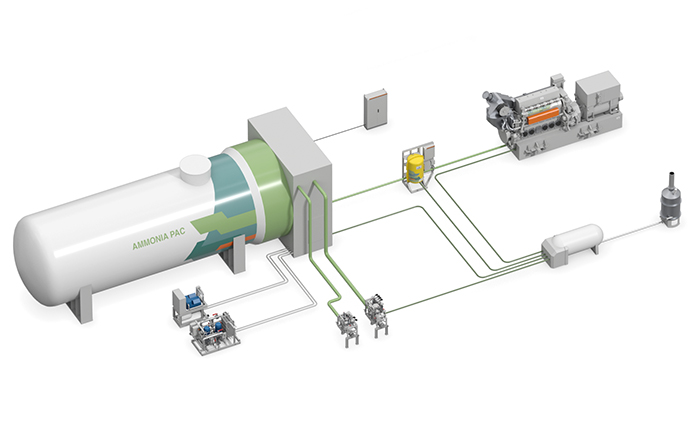

Liquefied natural gas (LNG) is a safe and cost-effective fuel that reduces greenhouse gas emissions and other harmful pollutants significantly compared to diesel fuel oil. LNG is playing a key role as a transition fuel and is widely seen as the first step towards decarbonising the maritime industry.

Fuel supply package: LNGPac for LNG

If you’re currently using diesel fuel oil, switching to methanol will reduce CO2 (tank-to-wake) emissions by up to 7%, SOx emissions by up to 99% and NOX emissions by up to 60% compared to HFO operation. Green methanol, produced using renewable energy, has the potential to be a carbon-free fuel.

Fuel supply package: MethanolPac for methanol

Energy saving technologies

Energy saving technologies help you reduce emissions by making small improvements in efficiency that add up to much bigger fuel savings. You can mix and match solutions for maximum gains. Adopt propulsion energy saving technology from Wärtsilä: proven solutions are available for the ship’s rudder, propeller, and propulsion control system as well as solutions such as rotor sails for wind-assisted propulsion.

Your ferry will save fuel thanks to its improved efficiency. This will also help comply to environmental regulations.

Ferry electrification

Flexible hybrid solutions help optimise propulsion efficiency. and allow zero-emission operations for short periods. Hybrid vessels can operate engines at optimal load, with batteries removing variable loads and acting as spinning reserve. This lowers fuel consumption and emissions, extends maintenance intervals and reduces noise.

Ferries that operate short routes between ports with the right electrical infrastructure can benefit from zero-emission, fully electric solutions using batteries.

Shore power retrofits: the demand for shore power solutions is increasing in line with the demand for hybrid and fully electric vessels. The ability to utilise onshore electricity is a requirement in many ports today.

Emission abatement

Wärtsilä’s emission abatement technologies include onboard carbon capture solutions (CCS), exhaust gas cleaning (EGC), and selective catalytic reduction (SCR) systems. They are designed to meet the strictest environmental standards.

Lifecycle services for ferries – for long-term reliability

Wärtsilä offers a full suite of lifecycle services. For example:

- Technical support – over a remote connection or face-to-face

- Maintenance and repairs

- Service agreements: A lifecycle agreement with Wärtsilä as your expert partner

- Lifecycle upgrades: Take full advantage of your investments while improving the efficiency and performance of your 2- or 4-stroke engines and other equipment.

Maintenance and repair services

Minimise downtime and keep your operations smooth with expert maintenance and repair services. From scheduled services to urgent repairs, our team is ready to support you: onboard, over a remote connection, at our workshops, or at offsite locations.

Lifecycle agreements with predictive analytics

A Lifecycle agreement with Wärtsilä can deliver you true peace of mind. Benefit from AI-powered solutions and predictive analyses together with expert knowledge. You can rest assured that your ferry will perform optimally and sustainably.

The scope of agreements can be tailored to fit your needs, to cover anything from ferry engines and power trains to propulsion solutions, fuel supply systems, and emission abatement technologies.

Customer stories from the ferry industry

Discover the benefits others have already gained from choosing Wärtsilä.

Insights for ferry operators

The ferry sector is spearheading whole marine industry’s journey towards zero-carbon operations. Discover the valuable insight from four forward-thinking professionals from the sector.

How to achieve successful decarbonisation

Robert Clifford, Founder and Chairman of Incat Group offers a simple solution for successful decarbonisation of ferry lines – but for one missing link. What is it?

Solving the decarbonisation challenge

Roberto Prever, CEO, NAOS Boat & Ship Design on the challenge of decarbonisation. Which fuel does he bring up and what does he say about it? What is his simple advice to owners at the end?

Explore decarbonisation strategies

Ferry fireside chats are analytical discussions on the issues raised in the ferry industry and in-depth updates on the future of ferry operations. These are insights gathered from the industry’s thought leaders who will help uncover the challenges, deep dive into the solutions available and find the route towards a zero-carbon future. All episodes hosted by Gina Panayiotou.

Profitable decarbonisation – A quick guide for ferry

operators

What you need to know about decarbonisation and compliance

Discover three proven strategies for ferry decarbonisation, with actionable steps and real-world examples from leading operators. This guide shows how to balance compliance, operational reliability, and business success on your journey to zero-carbon operations.

Hand-picked articles

Discover these hand-picked articles to learn about the many solutions for decarbonised and profitable ferry operations.

Latest news for the ferry industry

Why Wärtsilä for ferries?

- Help in balancing compliance requirements with daily operational needs

- A single point of contact and single responsibility

- Reduced risk of incompatibilities

- Time savings in design and engineering

- Simpler procurement procedures with lower timing and supply risks

- Fewer project participants enables faster decision making and fewer coordination difficulties

- Co-engineering with the yard’s design department

- On-site support during installation and commissioning

Frequently asked questions (FAQ)

Ready to future-proof your ferry operations?

Don’t let daily challenges slow your progress. Wärtsilä offers integrated propulsion systems, fuel-flexible engines, and lifecycle services to help you meet regulations and optimise performance. Connect with us today to start your journey.

The contents of this page have been written with the help of AI. All contents have been thoroughly checked and verified by human experts.