Reducing emissions to air

By choosing environmentally sound, energy-efficient technologies and low-emission fuels, marine and energy companies can help build a cleaner future. Many of Wärtsilä's products are designed to have a direct environmental benefit. By eliminating or reducing polluting discharges and emissions from our customer’s processes, we ensure that they can continue to operate in sensitive areas around the world.

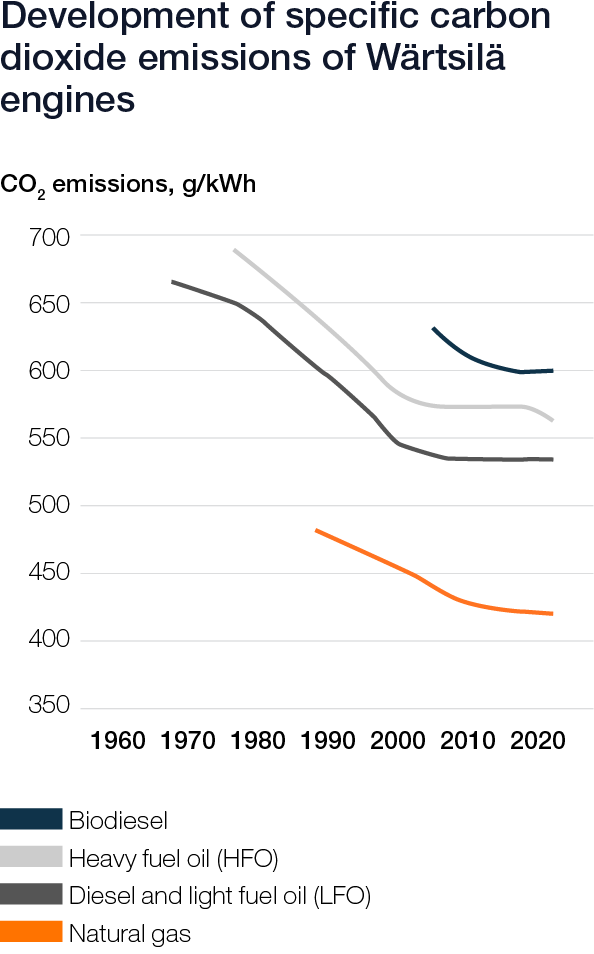

CO2 and other greenhouse gas (GHG) emissions

We develop technologies that reduce GHG emissions in numerous ways. These include gas and multi-fuel engines, as well as solutions for environmentally advanced vessels, voyage optimisation, and energy storage. Wärtsilä’s flexible energy solutions and research on future fuels, including hydrogen, ammonia, and synthetic fuels, enable a transition towards a 100% renewable energy future. Our energy efficiency engineering services also support significant reductions in GHG emissions.

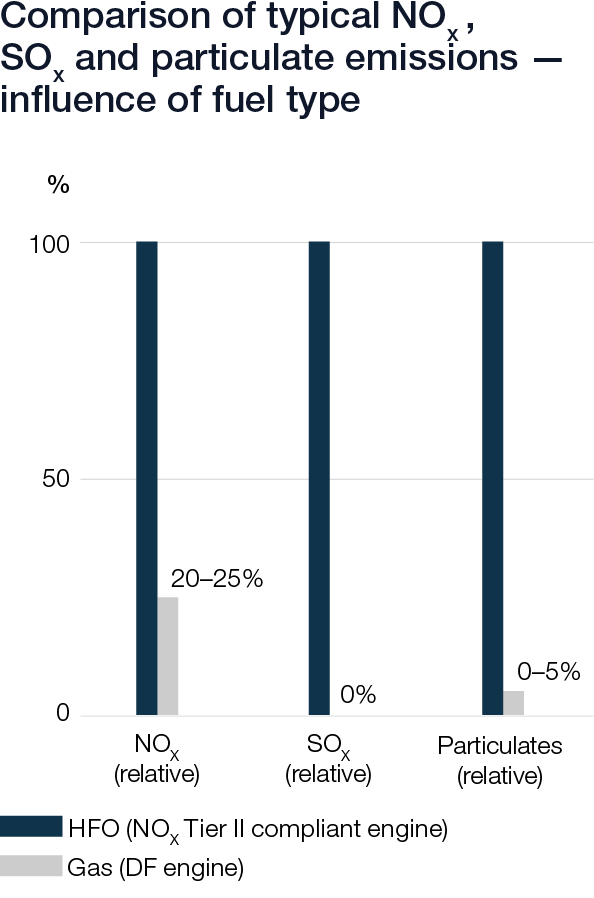

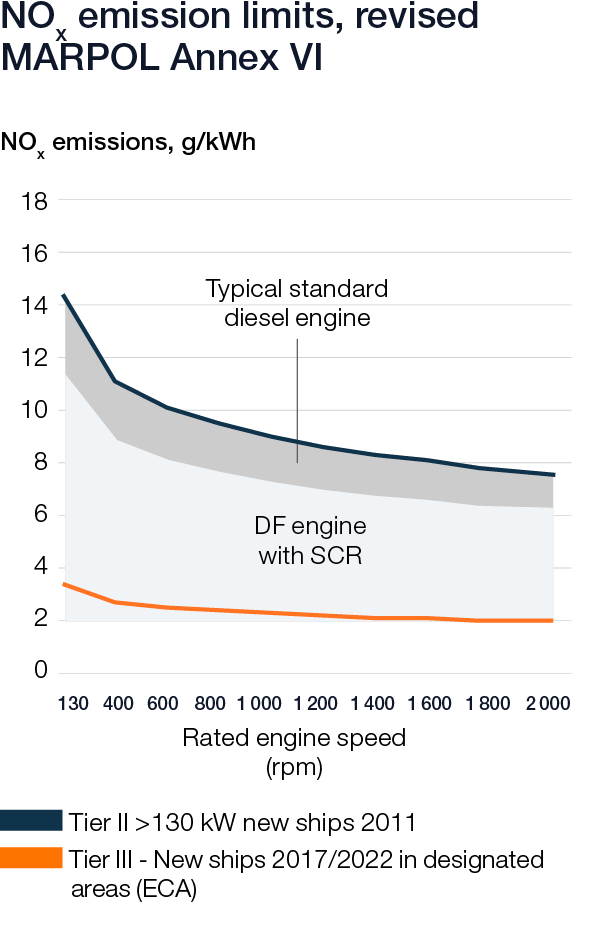

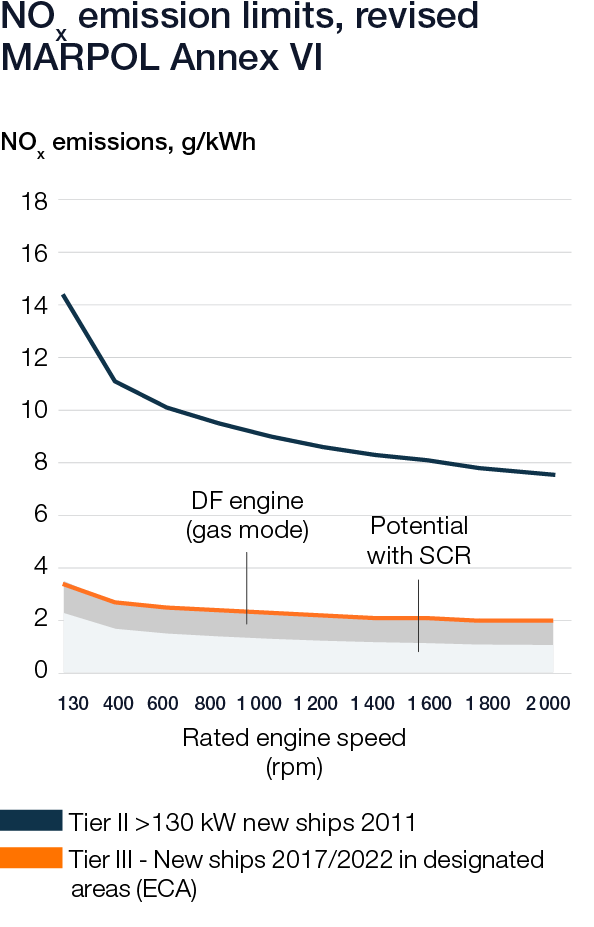

NOx reduction

A marine diesel engine installed on a ship constructed on or after 1 January 2016, and operating in the North American ECA and the United States Caribbean Sea ECA, must comply with the Tier III NOx standards. The same rule applies in the North Sea and Baltic Sea for ships with keel laying on or after 1 January 2021. This demands for further reduction of 75% in NOx levels from Tier II requirement. NOx reduction to Tier III level requires a step change in terms of engine technology and product offerings. Our entire marine engine portfolio is IMO NOx Tier II compliant, while our solutions for IMO NOx Tier III compliance include Selective Catalytic Reduction (SCR), dual-fuel engines in gas mode, and pure gas engines. The low NOx emission levels of our stationary engine-based power plants meet all current environmental regulatory requirements.

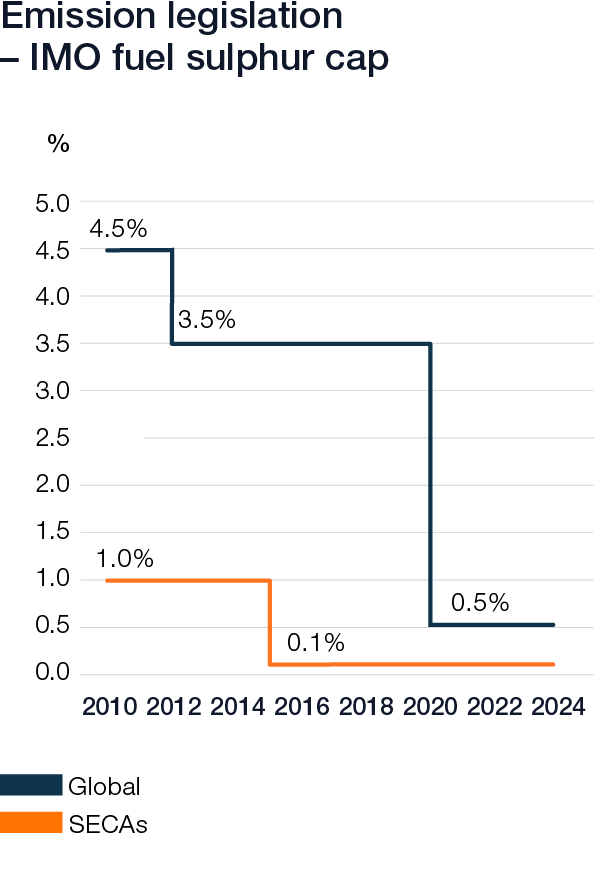

Marine SOx reduction

Since 2020, the current global limit for the sulphur content of the fuel oil used by ships has been 0.5% m/m (by weight). For vessels sailing in Sulphur Emission Control Areas (SECAs), the sulphur limit has been

0.1% m/m since 1 January 2015. Marine sulphur emissions can be reduced by:

- reducing the sulphur content of the fuel used

- removing sulphur from the exhaust gas

- operating on cleaner fuel such as liquefied natural gas (LNG)

We provide a number of solutions that help customers reduce SOx emissions and comply with local and global regulations. These solutions enable the use of fuels with different sulphur contents, including alternative fuels with close to zero sulphur content, such as natural gas. Our offering of exhaust gas cleaning systems (EGCS) not only reduce SOx emissions, but also remove large levels of particulate matter and black carbon. The Wärtsilä EGCS can be customised to meet both the 0.1% limit in Emission Control Areas (ECA) and the global 0.5% cap set by the International Maritime Organization (IMO).