Operational improvements and step change solutions for the Offshore Oil & Gas sector

The Oil & Gas sector is facing challenges to commit to emission reductions starting with 10% by 2025, 50% by 2030 and 90% by 2040. There is a gap between what is currently technically feasible and what is commercially feasible to deliver this ambition.

It starts with small steps. The opportunity to introduce relevant proven technology from other sectors that may be adapted for Oil & Gas use.

The time taken to achieve emission reductions from operational improvements reductions is shorter (perhaps one to two years) than from step-change actions which require much longer to define, develop and implement solutions (greater than five years) as these are large and more complex projects.

Wärtsilä is there as part of your decarbonisation journey. Starting with advice on what it is you can immediately do yourself and support you to meet your operational goals.

Looking for practical guidance?

This white paper explores proven solutions for offshore vessel design, upgrades and emissions compliance: Download now: “Offshore gains – How to tackle three challenges and sharpen your edge”

The journey to decarbonise the Oil & Gas industry

Operational Improvements & efficiency

In today’s competitive market, you will want to optimise your assets’ performance and maintain a positive environmental impact. After all, more reliable and efficient asset translate directly to better profitability – and to a more sustainable future.

Solutions that meet these requirements include technical advice on optimising your engines, upgrades of the propulsion system, and the latest digital technologies such as machine learning and artificial intelligence.

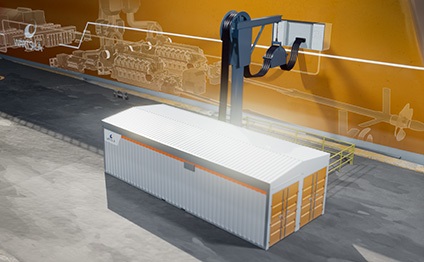

Electrification – an important change

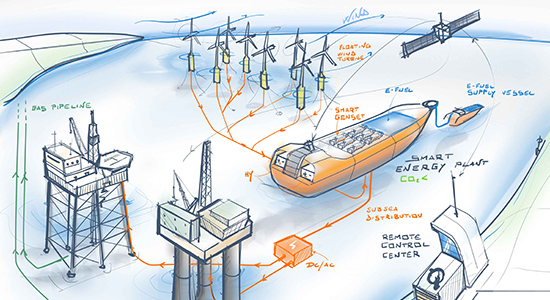

Electrification is part of the vision in the Oil & Gas market. When land-based electrification is not viable, one could set up an offshore floating energy hub with wind turbine power generation and swing generation from 4-stroke engines that would be fuelled either by green gas or by gas from the well. This concept would include proven technology: full or partial electrification of offshore assets through a connection to offshore renewables or to onshore power distribution networks.

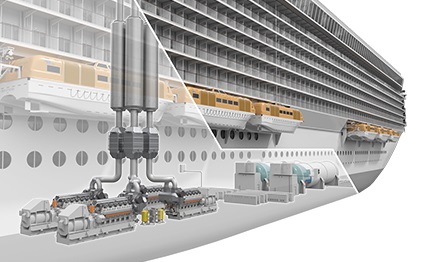

Alternative fuels and future fuel development

There is not a definite fuel of the future for the Oil & Gas sector yet. Fuel flexibility is therefore important, and Wärtsilä is developing solutions that will adapt to the green fuels of the future. Choose fuel flexibility and you will be prepared for the future. The state-of-the-art technology makes it possible to adopt clean fuels and rely on the proven combustion engines. It also helps comply with regulations, which can save you money without compromising reliability and safety.

Ensuring regulation compliance with your trusted decarbonisation partner

Reduce CO2 by 10% by 2025

- Day to day operations & reducing CO2 from the power generation process

- Audit & Recommendations

- Operational efficiency measures to reduce energy consumption

- Equipment upgrade and modification options

- Digital dashboards and artificial Intelligence (AI)

- Maintenance and reliability focus

Reduce CO2 by 50% by 2030

- Awareness of future fuel developments

- 4-stroke Future fuel conversion / retrofit packages

- Hybrid battery as back-up power

- Abatement technology – available within 3 – 5 years for CO2 reduction. Currently in development phase

Reduce CO2 by 90% by 2040

- Movement towards Electrification

- Hybrid battery and ESS

- Hub electrification Offshore Energy Hub

- Environmental consultation services