Advanced offshore solutions for efficient operations

As an offshore platform or vessel owner, you face the dual challenge of optimising operational efficiency while meeting stringent environmental regulations. Wärtsilä's offshore solutions are designed to address these critical needs.

When better fuel efficiency and lower emissions are your goal, you will appreciate our advanced technologies, such as powerful LNG engines, and hybrid solutions which include an innovative energy management system.

Offshore solutions that help you ensure compliance with the latest environmental regulations. Solutions that will also be optimal from both CAPEX and OPEX point of view.

Customised solutions for your unique challenges

For your unique offshore challenge, Wärtsilä will provide a tailored solution to meet your needs. With extensive experience and a proven track record, Wärtsilä is trusted by offshore operators around the world, delivering customised solutions that drive success.

Three recommended solutions for offshore

These innovative solutions help you ensure that your vessels are future-ready, environmentally compliant, and operating at peak efficiency.

Efficiency and cost reduction

Wärtsilä engines and generating sets, along with our advanced hybrid solutions, play a crucial role in improving efficiency and reducing fuel consumption and maintenance costs. As the offshore industry seeks to optimize operations and reduce expenses, our integrated systems deliver unparalleled performance and reliability.

Instead of only offering parts for vessels, Wärtsilä can deliver performance: integrated offshore vessel systems were the parts work optimally with the others.

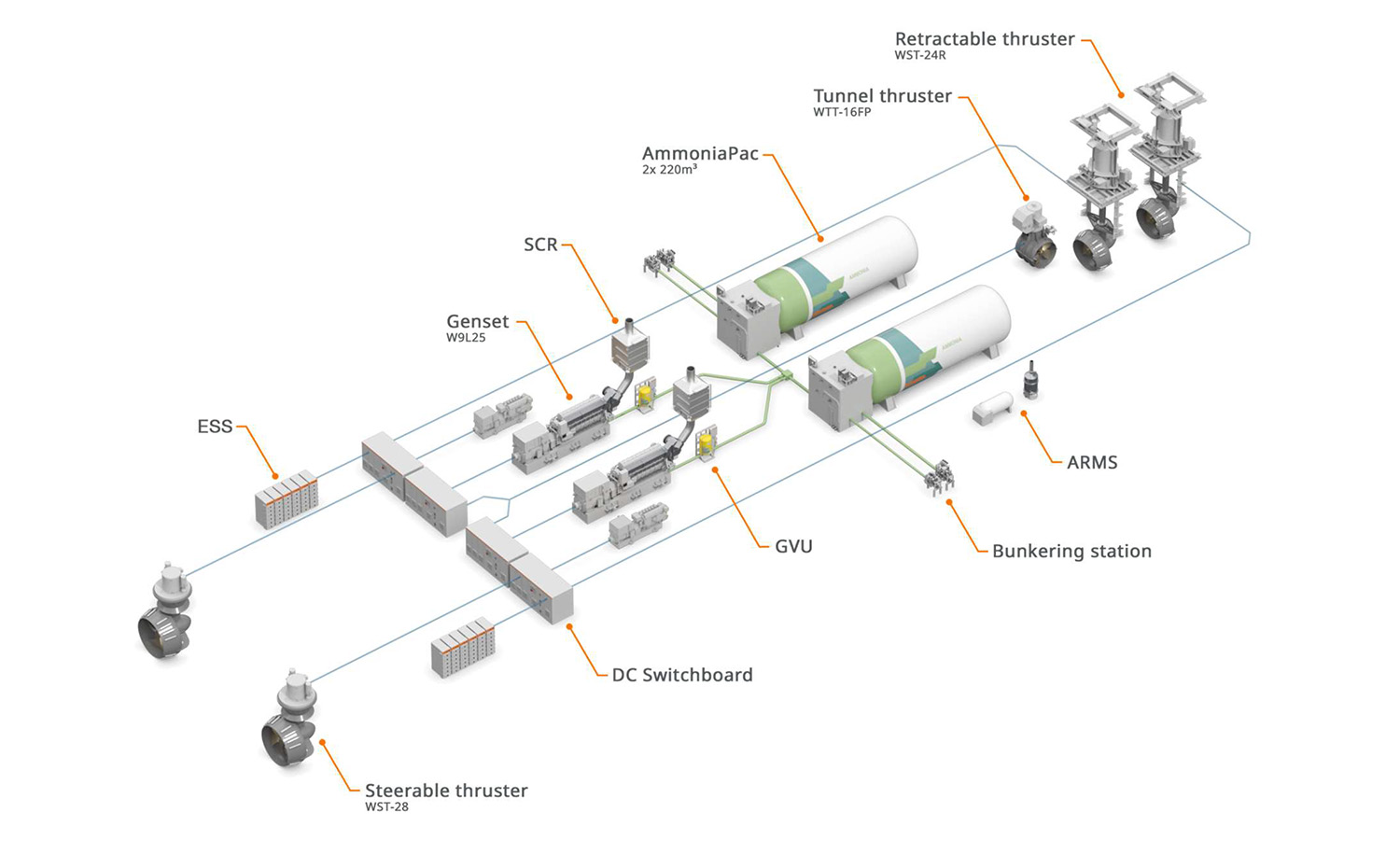

An integrated offshore vessel system may consist of the following, for example:

- Propulsion machinery including Wärtsilä gensets

- Thrusters: retractable, steerable and transverse/stern/bow thrusters

- Electric propulsion including an Energy Management System EMS

- Fuel gas supply systems for alternative fuels

- Environmental systems such as Nox reducer (SCR) and onboard carbon capture.

Environmental benefits

Cutting greenhouse gas emissions is more critical than ever, with ever-tightening regulations. You will appreciate the many solutions in Wärtsilä’s portfolio that drive sustainability.

Hybrid solutions

For example, the Wärtsilä HY hybrid system for offshore operations will save you fuel, especially when a vessel is in dynamic position operation. Fuel savings mean lower operational costs and fewer emissions.

The difference between a simpler hybrid system and Wärtsilä HY is the “brain” and the intelligent core, Energy Management System EMS. It integrates and controls the hybrid propulsion components in the vessel and makes sure that the power system works in an optimal way. It also safeguards the battery lifetime because it will not charge or discharge it over the allowed limits.

Alternative fuels

Wärtsilä is leading the way in developing a wide range of engine and fuel gas supply systems to help ship owners navigate the route to reduced GHG emissions – whatever fuels they choose.

Engines that run on methanol can offer tailored pathways to decarbonisation. Engines running on ammonia will also have a big role in the decarbonisation of shipping. For example, the Norwegian shipowner Eidesvik plans a world’s first ammonia-fuelled platform supply vessel (PSV) conversion for their Viking Energy PSV.

Wärtsilä’s modern engines are modular. This means that, as long as ship owners consider storage requirements, they can already plan to use new fuels on vessels being built today.

Thrusters for reliability and safety

Because ensuring reliable and safe operations is a priority in the offshore industry, offshore applications require excellent manoeuvrability. Wärtsilä’s portfolio of thrusters offers solutions for station keeping and manoeuvrability.

Thrusters work in extreme conditions and they must work safely and reliably, with minimal maintenance. Your safe choice will be a thruster proven in the field for many years. Wärtsilä has thrusters delivered over 30 years ago that are still in operation.

These are just two examples of customers who have selected Wärtsilä’s proven thrusters for their offshore vessels.

Windfarm construction vessel De Jian

De Jian, a heavy-lifting jack-up vessel owned by China Yantai Salvage uses Wärtsilä transverse thrusters to ensure excellent station keeping and manoeuvrability.

Sleipnir, the world’s largest semi-submersible crane vessel (SSCV) is designed for heavy lifting operations. Dynamic positioning is critical to its operations, and it uses Wärtsilä retractable, underwater mountable thrusters.

Trusted services and service agreements

From design to deployment and beyond, Wärtsilä is your trusted offshore lifecycle partner. You can get comprehensive support and services throughout the lifecycle of your offshore assets, ensuring optimal performance and long lifetime.

Case: Thruster maintenance for Noble Voyage drillship. Watch the video to learn how the team succeeded in the first phase of Noble’s fleet-wide thruster maintenance programme with precision and reliability.

Learn more about services: see the full suite of marine expert services from the Wärtsilä portfolio. This includes everything from genuine spare parts and technical support to maintenance and repairs.

When you are interested in a longer-term commitment to improving vessel uptime, saving fuel, and decreasing emissions, a service agreement with Wärtsilä is your smart choice.

Customer stories

Discover the benefits others have already gained from Wärtsilä solutions for offshore applications.

Customised solutions for your unique challenges

Your offshore challenge is unique, and we can provide a tailored solution to meet your specific needs. With extensive experience and a proven track record, Wärtsilä is trusted by offshore operators around the world, delivering customized solutions that drive success.

Choose Wärtsilä as your trusted partner in offshore solutions and equipment. We are dedicated to powering decarbonisation with sustainable solutions and to boosting your offshore operations efficiency through integrated solutions.

Facing offshore challenges?

Discover how to improve safety, efficiency and sustainability with real-world strategies.

Take the easiest next step: get in touch and let’s discuss how we could help you solve your unique offshore challenges.