Article original published by the Motorship 28.11.2023

Agreement has been reached between the European Parliament and Council on a new EU Regulation to reduce energy sector methane emissions in Europe and for imports.

The new regulation will oblige the fossil gas, oil and coal industry to measure, monitor, report and verify their methane emissions according to the highest monitoring standards, and to take action to reduce them. It requires operators to report regularly and to carry out regular surveys of their equipment to detect and repair methane leaks within specific deadlines. It also bans routine venting and flaring.

Hans Jakob Buvarp, General Manager, Sales at Wärtsilä Gas Solutions

The EU imports a large proportion of the oil and gas it consumes, so the regulation also requires the Commission to establish methane performance profiles of countries and companies to allow importers to make informed choices. And as of January 2027, the regulation requires that new import contracts for oil, gas and coal can be only concluded if the same monitoring, reporting and verification obligations are applied by exporters as for EU producers.

A cumulative problem

A recent Horizons report from Wood Mackenzie notes that methane is responsible for almost a third of the emissions-induced increase in global temperatures since the start of the industrial era, and the oil and gas industry is estimated to account for up to a quarter of anthropogenic methane emissions. According to Wood Mackenzie’s Emissions Benchmarking Tool, typical methane losses per field are small - less than 500 kilogram per hour (around 0.65 million cubic feet per day), which is below the measurable resolution of most current satellites - but around 96% of all fields have emissions on this scale, making it a large, cumulative problem.

The new EU regulations will add to existing voluntary abatement initiatives. Larger international oil companies and an increasing number of national oil companies have committed to methane reduction targets, but to date these have mostly been voluntary efforts. Regulatory efforts have so far lacked teeth, says Adam Pollard, Principal Analyst, Upstream Emissions, Wood Mackenzie.

Methane in VOC

Volatile organic compounds (VOC) are light components of crude oil, which evaporate during loading operations or during the carriage of high-volatility crude oil cargoes. Methane concentrations in VOC vary widely but can reach 5% which for a VLCC can amount to 23 tons per loading. So, although the new EU regulations don’t appear to specifically target VOC emissions resulting from oil cargo loading and unloading operations, the volumes released make them a potential future target.

Like other upstream methane emissions, they represent a cumulative problem, and venting to the atmosphere represents both an environmental problem and a significant loss of energy. VOC emissions from global sea transportation are estimated to exceed five million tonnes per year.

The technical feasibility of recovering VOC from shipping has already been proven. Wärtsilä developed a VOC recovery system for cargo operations that has been operating on shuttle tankers in Norway’s offshore oil fields since 1990s. The region’s local regulations and somewhat unique use of shuttle tankers rather than pipelines have driven demand for the system. There’s currently about 10 in operation, others have since been retired.

The solution has been effective, but it hasn’t yet taken off in other regions: the release of VOC emissions during oil tanker loading has not been heavily regulated even though methane emissions from gas carriers during loading and unloading operations are highly regulated. That may change with the new EU regulations or more ambitious voluntary targets. Member companies of the Oil and Gas Climate Initiative’s (OGCI) Aiming for Zero Methane Emissions have already reduced upstream methane intensity by nearly 45% in the past five years.

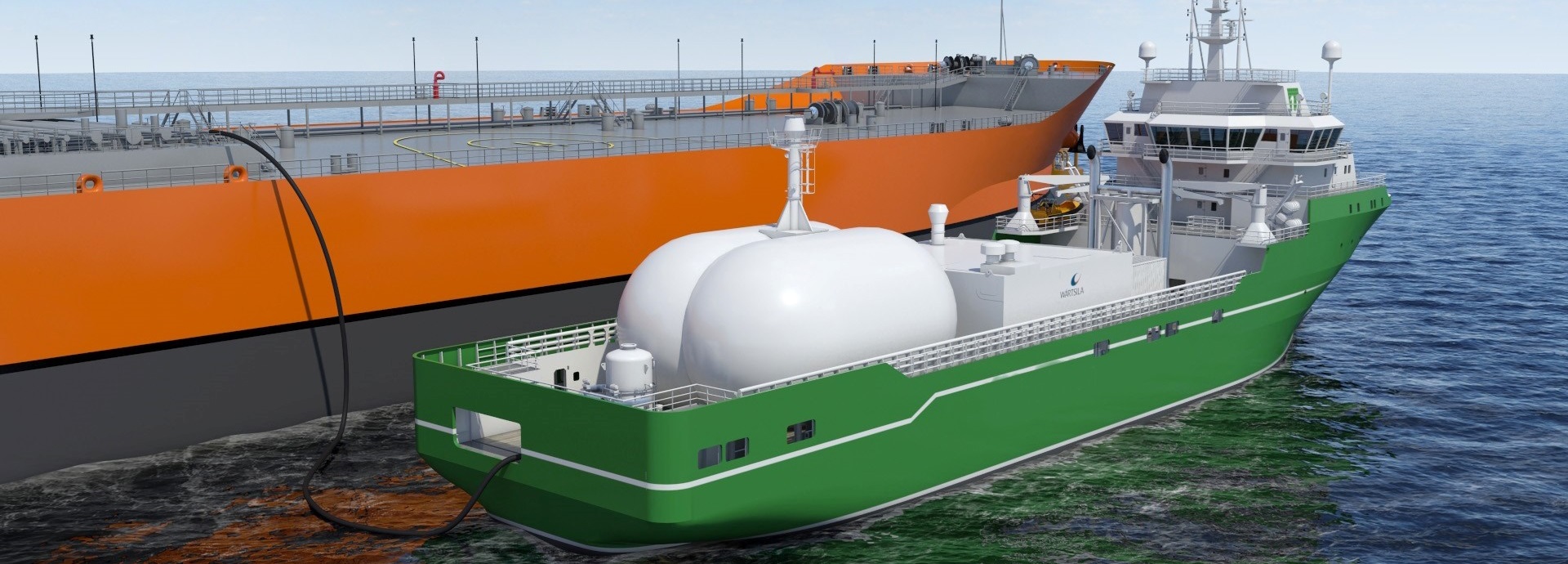

VOC recovery vessel

Hans Jakob Buvarp General Manager, Sales, at Wärtsilä Gas Solutions, is optimistic that VOC emissions will become a future focus for the oil industry and says the company is ready with a solution. In partnership with the Norwegian company Vaholmen VOC Recovery and Ulstein Design & Solutions, a DP2 VOC recovery vessel design that can support VLCCs with VOC recovery during cargo operations has been developed. The system will remove all VOC emissions during loading, and the VOC recovery vessel will be able to serve several VLCCs before unloading the liquified VOC onshore.

The vessel is equipped with a VOC recovery system similar to that employed on the shuttle tankers already in operation. It is connected by hose to the vapour connection on the manifold of the VLCC during loading. The VLCC connection features a blind flange, while the VOC recovery vessel connection features a quick release assembly.

Once the connection is made, the VOC is routed through the VOC recovery system, which uses a two-stage condensation process. Following the removal of the heavier fractions during the first stage, a second stage condenses the medium fractions (from propane to hexane) into a liquefied VOC stage.

The light fractions of the VOC (methane and ethane), along with some vaporized liquified VOC, are combusted in the VOC recovery vessel's three gas turbines, ensuring that all VOC is utilised. The main part of the liquified VOC is exported to shore where it is reinjected in the crude storage tank or exported for further refining.

Although onboard combustion of the VOC generates CO2 emissions (one tonne of methane creates around three tonnes of CO2), the untreated methane is a 28 times more potent greenhouse gas. “Same with VOC. It is around five to six times worse than CO2,” says Buvarp. “It’s better that you convert it into power.”

The solution offers significant greenhouse gas emission savings, as cargo loading accounts for 70% of total VOC emissions from ships. Using a VOC system would yield net CO2 equivalent (CO2e) savings of 1,500-2,500 tonnes per loading of a VLCC. The use of the VOC system does not have any impact on the rate of loading and is designed for offshore installations, single buoy moorings, sea islands or terminals. System size can be adapted to the loading capacity of the terminal, with a typical capacity being around 20,000 m3/hour.

One of the key advantages of using a VOC recovery system installed upon a dedicated vessel for loadings is that the utilisation rate for the equipment would be high and constant. “You can imagine that a single VOC recovery vessel serving 150+ VLCC loadings per year could generate tremendous total savings,” says Buvarp. While it’s technically feasible to install the system on a VLCC, the economics don’t stack up considering that the vessel may only load cargo six times a year.

A new market dynamic

Finding offtake for the VOC has been a stumbling block in the past, but he is seeing market developments for the vessel design and shuttle tanker solution, particularly in the Middle East. “The Arabian Gulf has a lot of single buoy moorings, and they export around 50% of the oil worldwide so they are a big market for us,” he says.

Using a VOC recovery system (pictured) for loadings would reduce emissions by up to 1,500-2,500 tonnes per loading of a VLCC. © Ulstein Design & Solution

The US has become another target market. VOC may be viewed as a net-zero fuel for LPG carriers, for example, and the US EPA is now paying greater attention to VOC management, with regulation on the way.

Buvarp sees the IMO’s increasingly stringent CII and other regulations as driving interest in VOC as a net-zero fuel. Liquified VOC is a potent fuel with a calorific value similar to LPG and LNG. However, the Methane number is low, so while it can be used in a diesel cycle engine as the only fuel, it cannot be used alone in an Otto type combustion engine due to knocking. Vaporised LVOC can be used in gas turbines and boilers without any pilot.

VOC has been approved by MAN Energy Solutions as a potential fuel in the MAN B&W ME-LGIP engine. MAN has indicated that the LPG engine has great potential for being a solution to handle VOC on shuttle tankers and other crude oil carriers because the engine can burn any mixture of propane and butane, and furthermore, the mixture can contain significant amounts of ethane. All heavier hydrocarbons normally contained in the liquified VOC can be used as well.

Buvarp notes that BW Gas has already retrofitted some of their ships with suitable fuel supply systems and two storage tanks that hold around 2,000 cubic metres in total. This is enough to fuel a voyage from the Arabian Gulf to China.

This concept could also become an attractive proposition, he says. Installing or retrofitting LPG engines on VLCCs would enable the use VOC as fuel, a more financially viable concept than storing the VOC and offloading it ashore.

Wärtsilä is currently engaging with partners in the EU to have VOC recognised as a net-zero fuel by regulators, then, says Buvarp, VOC will become very attractive.

Related solutions

Did you like this? Subscribe to Insights updates!

Once every six weeks, you will get the top picks – the latest and the greatest pieces – from this Insights channel by email.