Controllable Pitch Propeller (CPP) systems

Wärtsilä Controllable Pitch (WCP) propeller systems provide excellent performance and manoeuvrability, and are recommended for vessels with frequent sailing routes that involve multiple operating conditions. These can be, for example, vessels requiring full power in both bollard pull and freesailing conditions, or that make frequent port calls. WCP propeller systems can also be applicable for vessels that encounter varying weather conditions or demanding operational requirements such as dynamic positioning.

A controllable pitch propeller is often the optimal choice for installations with a shaft generator operating at constant rotational speed. Full propulsion power is available in both heavy and light conditions through an automatic pitch adjustment. Engine overload is avoided regardless of the conditions.

The WCP propeller system is the ideal choice for diesel-mechanic propulsion with both medium-speed and low-speed diesel engines. By integrating a suitable gearbox and Power Take Off/In, the WCP propeller system can be transformed into a hybrid propulsion system that enables:

- High operational efficiency and flexibility

- A power boost mode

- Emergency propulsion power

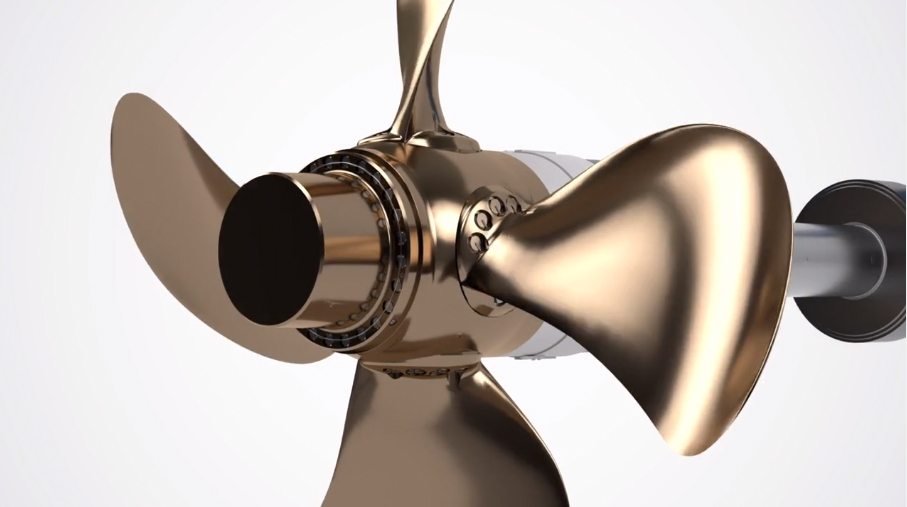

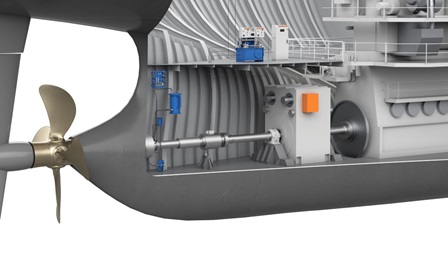

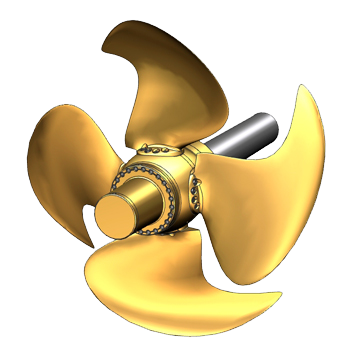

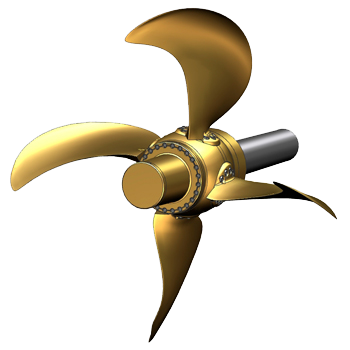

A Wärtsilä Controllable Pitch (WCP) propeller system is a fully customized combination of a hub, propeller blades, shafting, hydraulics and a control system, as well as any further accessories needed to meet the customer’s needs. Wärtsilä’s hydrodynamic experts tailor the propeller for each application to achieve the optimum balance between fuel consumption and comfort levels as set by the customer.

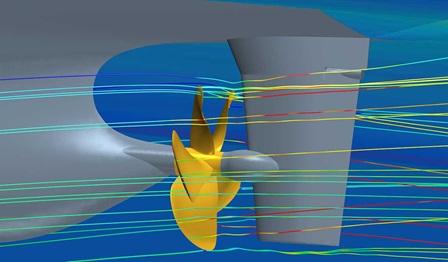

Wärtsilä Controllable Pitch (WCP) propeller systems deliver excellent performance and efficiency, while minimizing noise and vibration levels.

- A customised propulsion system tailored according to customer requirements

- A reliable propulsion solution for dynamic positioning (DP) and ice class applications

- Available with a pollution free stern tube arrangement

- The Wärtsilä OPTI Design propeller methodology takes into consideration the full-scale interaction between the propeller and hull, thereby ensuring optimized efficiency

- Less maintenance and easy installation

- User friendly and intuitive operations with Wärtsilä ProTouch control panels

- Increased fuel savings achieved with the EnergoPac, EnergoProFin, Wärtsilä EcoControl, HP nozzle, feathering hubs and OPTI Design

- Lubrication system available with moisture content monitoring

Wärtsilä’s Controllable Pitch Propellers help P&O Ferries navigate the English Channel

The MS Pride of Canterbury has been a fixture at Dover for the past 25 years. When her owners, P&O Ferries, decided it was time for a new life for the ferry they turned to Wärtsilä.

“With a new car, as a general rule of thumb you use the main dealership and OEM for servicing and maintenance,” explains Wärtsilä’s Ross Murphy, Manager, Product Services, Propulsion. “It is often the same with ships. Many of P&O Ferries' were originally fitted with Wärtsilä equipment when they were built, so now they come back to us for overhauls and service.”

Around 20,000 vessels in the world are working with Controllable pitch propellers (CPP) and every 4th vessel has a Wärtsilä CPP.

Blazing new trails in Arctic shipping

The Baltic sea is one of the most important trade routes in the world, and even today, at any time, nearly 2000 vessels are operating along this route carrying general cargo, liquid bulk and dry bulk. Over 400 ports dot the different regions surrounding the sea, with at least 90 of these playing a significant role in international trade.

Experts estimate that over 50% of the vessels operating along this route are general cargo vessels, with another 20% being tankers carrying oil. Even the pandemic seems to not have dampened trade volumes with most Baltic ports reporting relatively stable numbers. But that is not to say that this maritime route does not have its share of challenges.

Download Brochures

Technical information

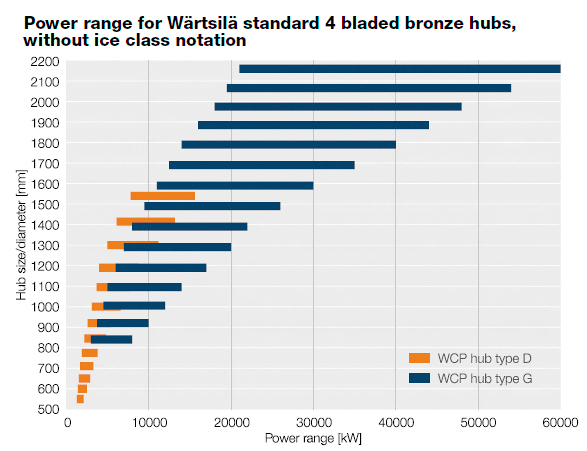

Power range starting from 500 kW, no upper limit

- 4- or 5-bladed propellers starting at a diameter of 1200 mm

- Bronze or stainless steel propellers

- Various hub types, depending on the application

- Compliant with all ice classes.

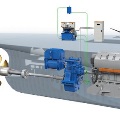

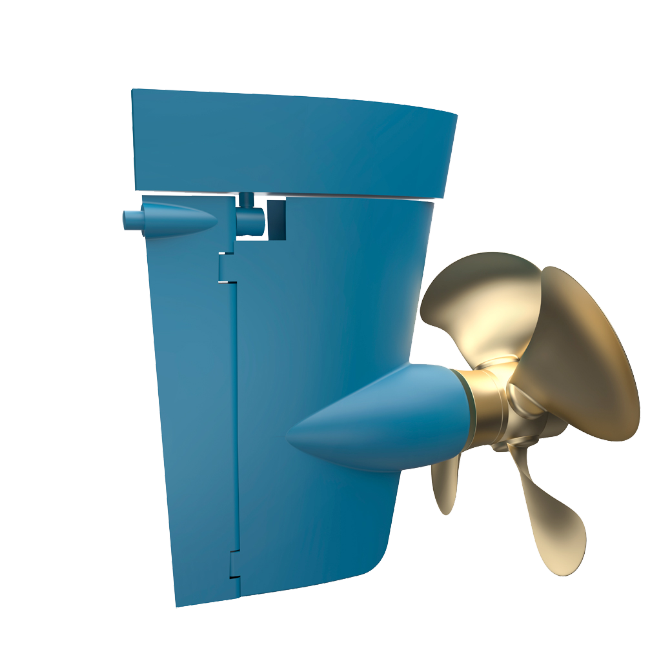

WCP propeller systems are generally available in three categories:

- With a reduction gear box and with the oil distribution unit connected to the forward end of the gear box.

- With a reduction gear box that produces the hydraulic pressure for pitch actuations.

- For direct drive without a gear box.

The WCP propeller system can comply with the EPA Vessel Permit 2013 requirements and can be delivered with environmentally acceptable lubricants (EAL). The Wärtsilä stern tube system can ensure zero pollution.

Underwater replacement of the blades, hub disassembly without pulling the shaft, easy installation, reduced maintenance, and a customised efficient propeller design with minimal noise and vibration are further benefits of the WCP propeller system.

Wärtsilä has the unique market position to select various controllable pitch hub principles up to 16 MW. The WCP hub type D is the right solution for light and moderately loaded propellers. The WCP hub type G is selected for vessels requiring a high power or a highly loaded propeller. With these hub types Wärtsilä manages to successfully cover the complete market segments that requires controllable pitch propellers.

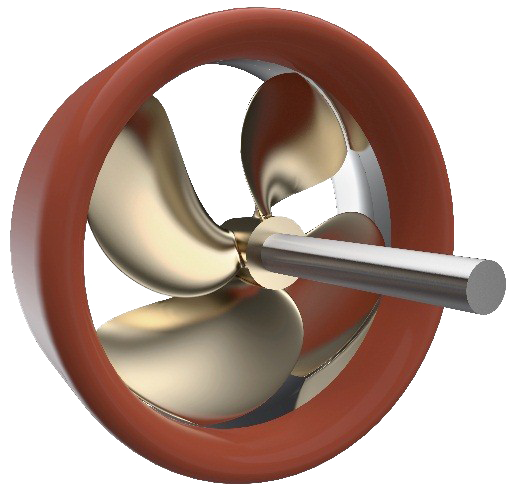

HP nozzle

Fitting a nozzle increases the thrust at relatively low ship speeds. This allows for significant savings to be achieved in terms of fuel consumption, depending on the number of revolutions and the capacity of the engine. The improved Wärtsilä High Performance nozzle, type HP nozzle, when combined with Wärtsilä propellers, can provide up to 5% more thrust than conventional nozzles in bollard pull conditions. The nozzle profile offers a double profiled cross section at the inlet side of the nozzle.

The HP nozzle can be combined with either fixed pitch or controllable pitch propeller systems, and are typically installed on heavy duty vessels, such as:

- Tugs and push boats

- Anchor Handling Ships

- Trawlers

- Dredgers

- Ice navigation vessels

and on low speed vessels such as:

- Inland navigation vessels

- General cargo vessels

Feathering hubs

Feathering propellers are applied to save fuel for multi-functional vessels that operate in such a way that one or two propellers are regularly out of use. The ability to position the propeller blades for feathering achieves less resistance and lower fuel consumption than with a Trailing or Blocked propeller.

TYPICAL APPLICATIONS

- Double ended ferry With propellers at both the bow and stern of the ferry, the foremost propeller is not in operation during transit.

- Twin screw vessels Twin screw container or cargo/RoRo vessels operating with one propeller at low speed for longer periods, for example when the sailing route involves both high and low speed operation.

- Vessels with a booster propulsor Vessels with a centre propeller and wing thrusters have the possibility to operate on only the thrusters when a lower sailing speed is required

- Vessels with alternative propulsion Sailing cruise vessels or sailing yachts use wind propulsion and feathering propellers to minimise resistance when the mechanical propulsion system is not in use.

An additional feature of a feathering propeller in a twin screw propulsion layout is the possibility to perform maintenance and overhaul on one of the shafts while continuing operations.

Ahead propulsion position

Ahead propulsion position

Feathering position

Feathering position

EnergoProFin

The Wärtsilä EnergoProFin is an energy saving propeller cap with fins that rotate together with the propeller. This solution provides average fuel savings of 2%, with a payback time of less than one year.

The propeller’s energy

losses are among the factors related to the flow phenomena around and behind the propeller boss. Installing the Wärtsilä EnergoProFin helps to reduce these energy losses and increase overall propulsion efficiency.

The Wärtsilä

EnergoProFin is suitable for all newbuilds and existing vessels.

EnergoPac

- EnergoPac is the optimised propulsion and manoeuvring solution for ocean going vessels

- Proven fuel saving technology for controllable and fixed pitch propeller applications

- Advanced hydrodynamic technology is applied to reduce the vessel’s fuel consumption using an integrated propeller and rudder design

- Outstanding vessel manoeuvrability made possible in co-operation with Hamburg-based Becker Marine Systems, the market leader for high-performance rudders

- Improved onboard comfort levels compared to conventional propeller and rudder configurations

CPP services

The solution covers everything from inspections and maintenance to emergency repairs and modernisation or complete replacement of CPP systems. The Wärtsilä service for pitch propellers keeps your installation running smoothly by increasing the reliability while reducing OPEX and ensuring long-term visibility into costs.

Wärtsilä Controllable pitch propeller services provides a quick, efficient, and cost-effective solution while providing support throughout the lifecycle of your equipment. With our services we can support you with scheduled inspections and unplanned repairs, and help you realise fuel-efficiency gains.