Hybrid propulsion system for ships – Wärtsilä HY

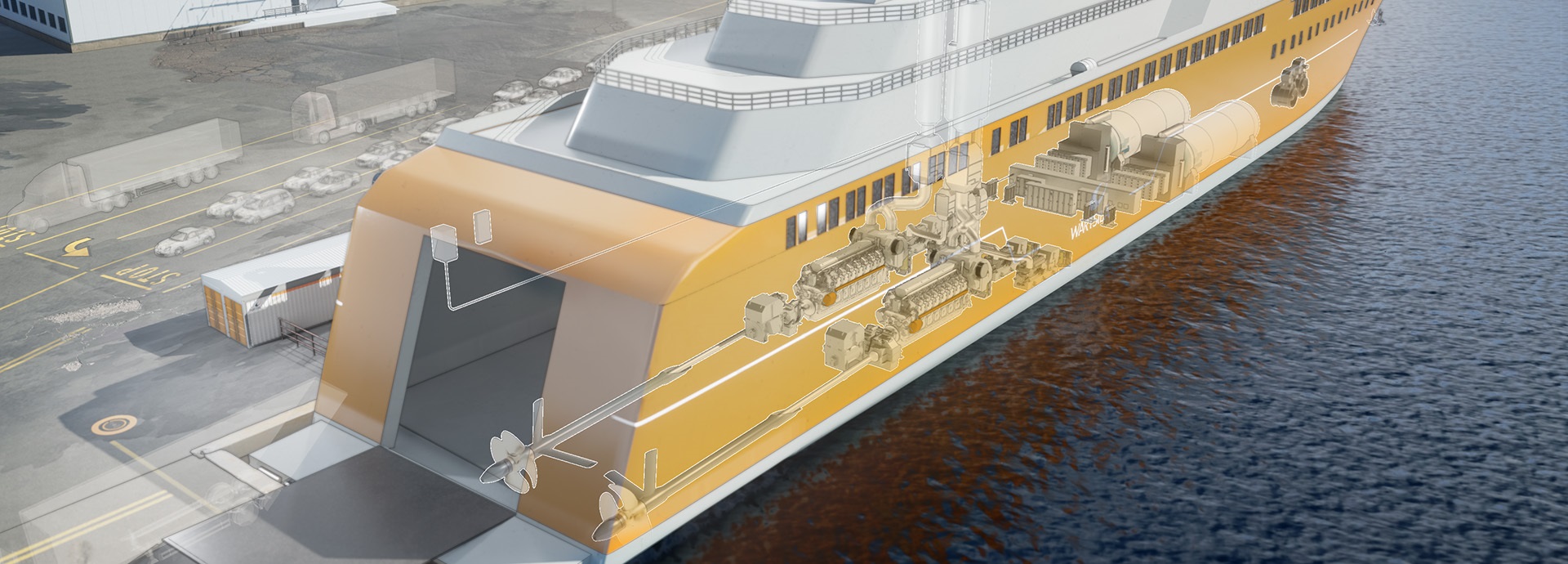

A hybrid propulsion system for ships combines conventional engines with energy storage. The Wärtsilä HY system combines engines, energy storage, and an intelligent Energy Management System into one integrated solution. It helps ship owners reduce fuel consumption and emissions, improve operational efficiency, and meet tightening regulatory requirements for newbuild and retrofit projects.

Hybrid propulsion system at a glance

What it is: Integrated engines + energy storage + EMS

Why it matters:

- Up to 10–15% fuel savings in transit

- 25–40% fuel cut in DP standby

- Lower EU ETS costs and FuelEU compliance

- Improved CII/EEXI ratings

Where it works: Ferries, tugs, merchant ships, offshore vessels

How it helps: Optimized power flow, reduced engine hours, OPS readiness

What is a hybrid propulsion system?

A hybrid propulsion system adds a battery to the conventional engine setup and manages both as one system. The system optimises the engine load based on the vessel speed and operating profile. Engines can be run at optimal load, where they are most efficient and generate the least emissions, while batteries absorb load fluctuations.

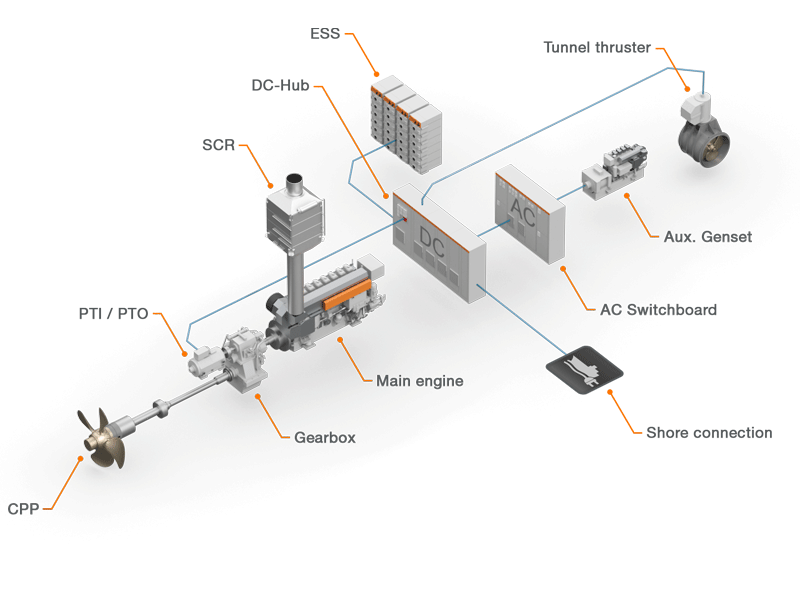

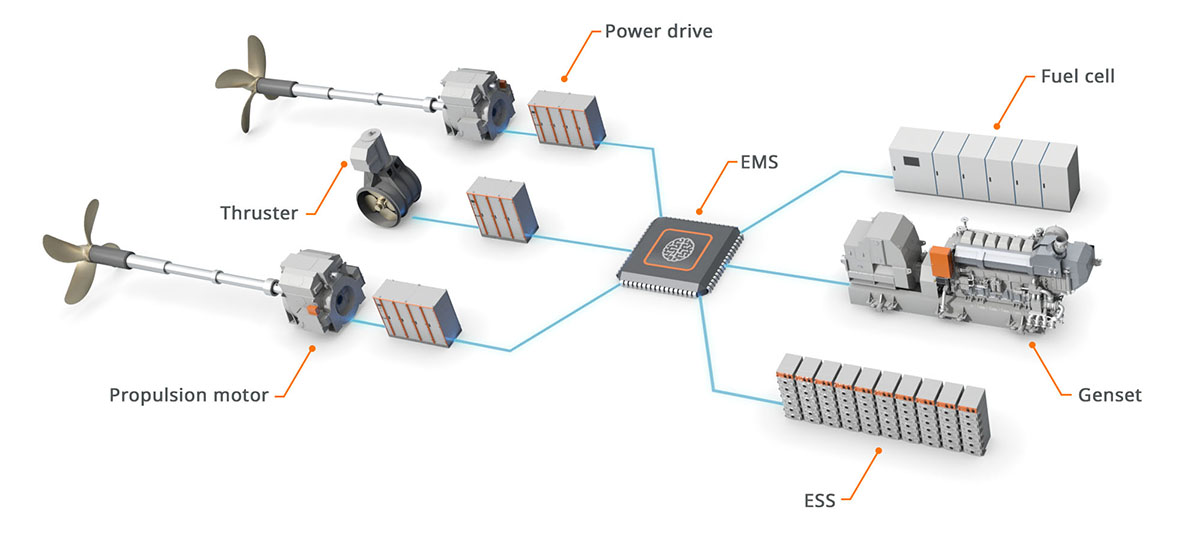

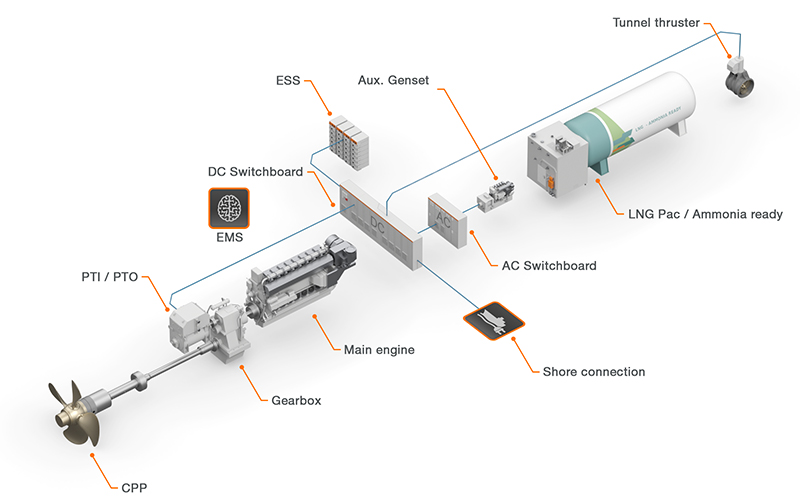

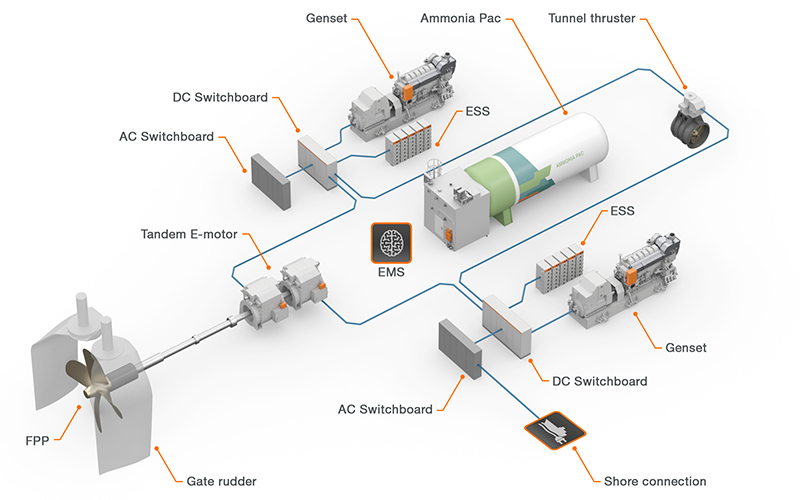

Key components of Wärtsilä HY

Wärtsilä HY consists of specifically engineered components – the engine, power drives, and the energy storage system also with optional fuel cells. Its “brain” is the Energy Management System EMS, which controls the flow of energy between different power sources.

In Wärtsilä HY, all hybrid propulsion components work together optimally, in unison. This is why Wärtsilä HY delivers superior levels of integration and control, compared to solutions which only add an energy storage to the propulsion system.

“A hybrid ship with Wärtsilä HY can operate in different modes and thus respond to the changing conditions in an optimal way. Its flexibility allows it to save fuel, and its overall performance is better as well.

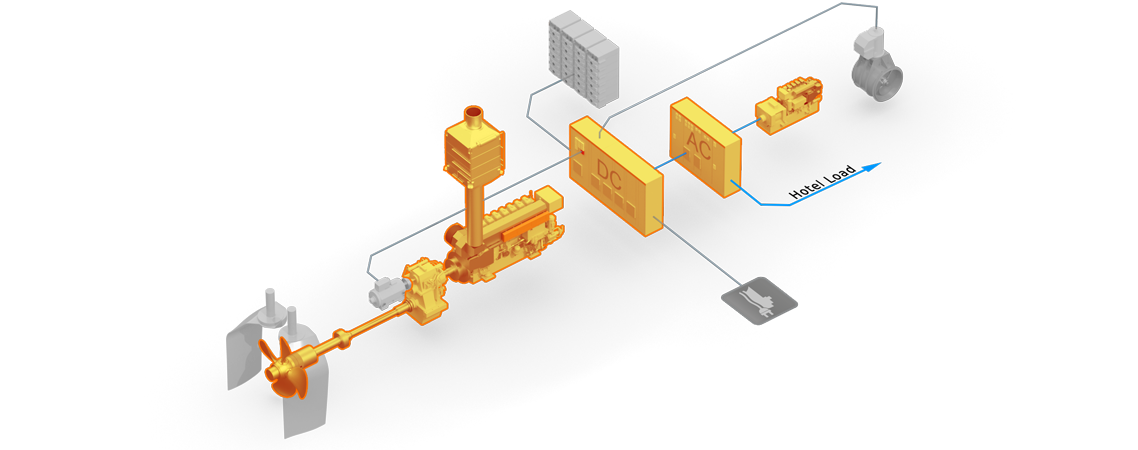

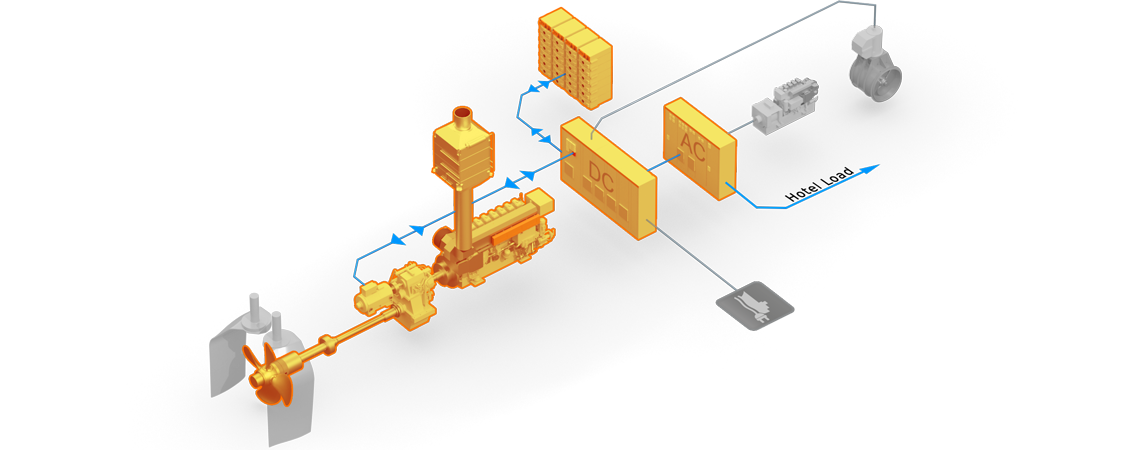

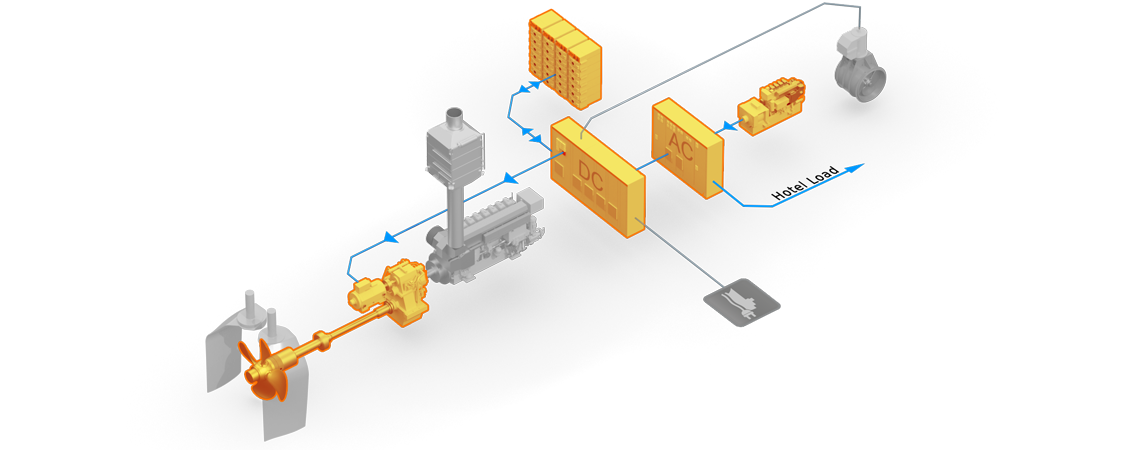

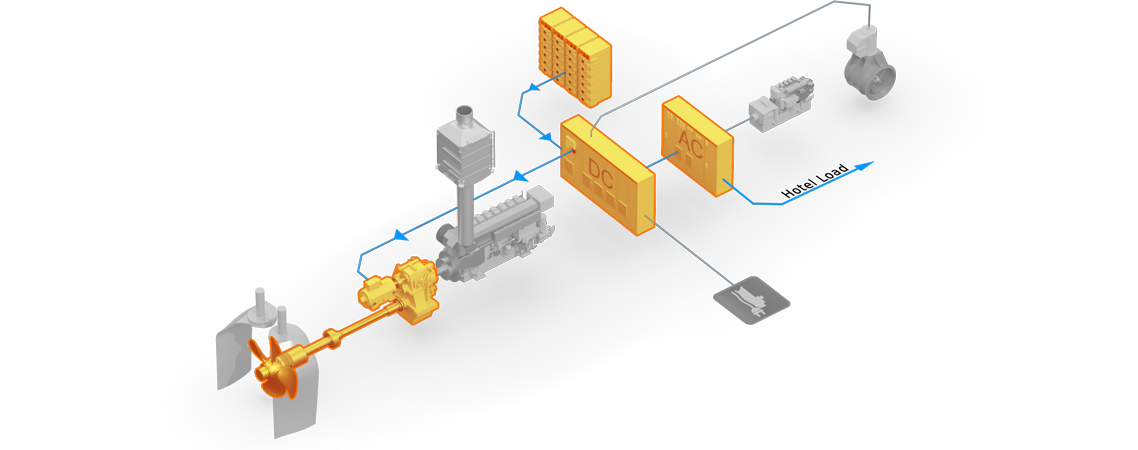

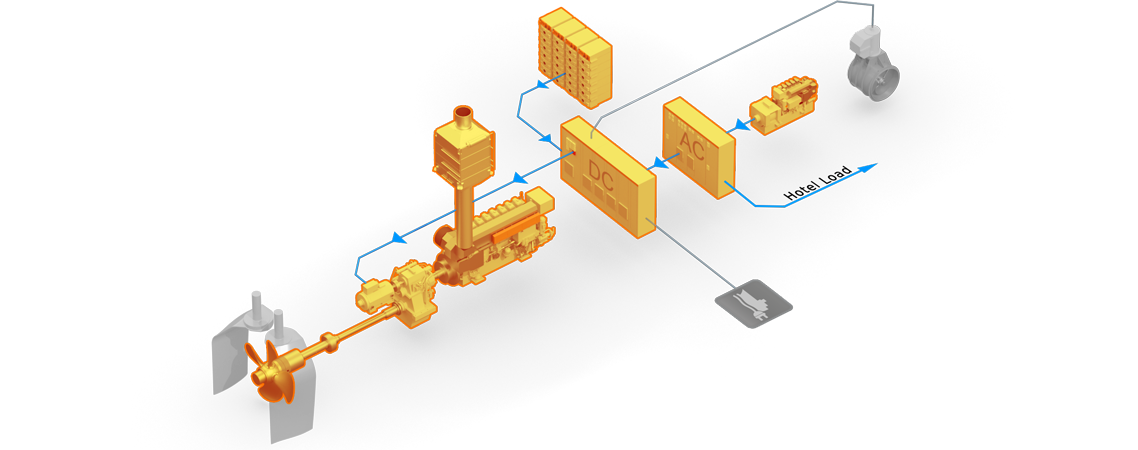

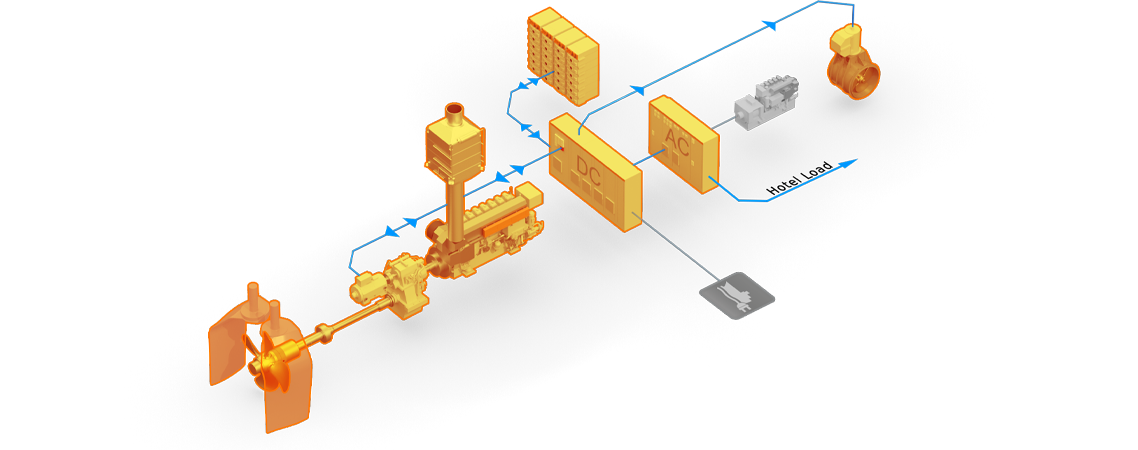

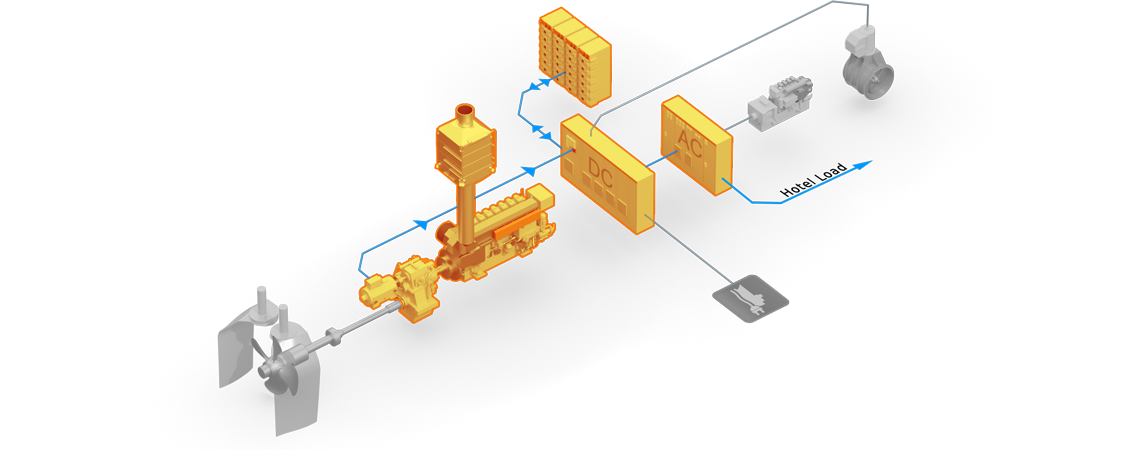

How Wärtsilä HY works

Wärtsilä HY balances mechanical and electrical power. It is a coordinated system of

- Propulsion engine

- Power drives for PTO/PTI/PTH

- Energy storage system (ESS)

- The intelligent Energy Management System (EMS)

With a power take-off/power take-in (PTO/PTI) gearbox, the shaft generator can reuse surplus engine power to charge the batteries (PTO) and provide a boost in propulsion power when needed (PTI). This significantly improves the vessel’s energy efficiency and operational flexibility.

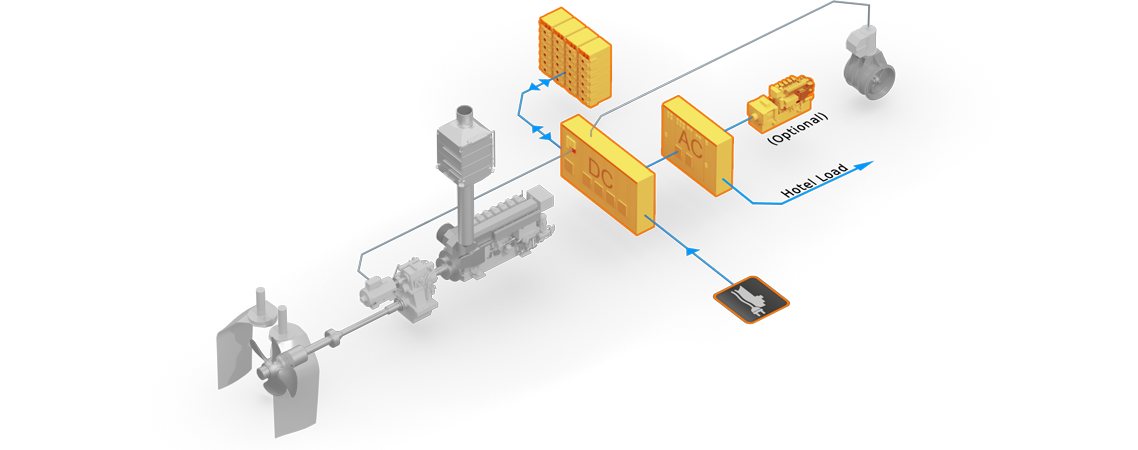

Energy Storage System (ESS) handles fast fluctuations and peak shaving. It also enables silent, emission-free operation in port.

Energy Management System continuously monitors load, vessel state, and operating mode, then routes power to maximise efficiency.

Common configurations at a glance:

Wärtsilä HY supports diesel‑mechanical with PTO/PTI/PTH, diesel‑electric with DC hub architectures, and shore power/charging integration. Your EMS coordinates these elements so you can operate in harbour, transit, DP, and boost modes with the right mix of mechanical and electrical power.

Related reading:

Explore the Electric propulsion systems page and Electric shipping main page for deeper technical context on shaft generators, shore connection, and charging strategies.

Energy Management system – the intelligent core

The Energy Management System EMS integrates and controls the hybrid propulsion components in the vessel. It is the “brain” and the intelligent core of Wärtsilä HY. The EMS makes sure that the power system works in an optimal way. It also safeguards the battery lifetime because it will not charge or discharge it over the allowed limits.

The following are examples of the key role that EMS has in the optimal operation of the hybrid ship:

Spinning reserve. It may be necessary to run an additional genset for safety reasons, for example in Dynamic Positioning mode, in manoeuvring or in confined waters. The battery can serve as spinning reserve instead, replacing the additional genset, which would usually be running at low load.

Green mode with zero exhaust emission. When the vessel operator selects this mode, the EMS makes sure that all power will come from the energy storage system (the vessel battery). This will continue until the battery level reaches its pre-set minimum.

Start-and-stop. When the engines are operating at low load, the EMS ensures that all power for propulsion will come from the energy storage system. This will continue until the battery level reaches its pre-set minimum. When that happens, the EMS automatically re-activates the engines. The engines provide the propulsion power to the vessel and they also re-charge the vessel batteries.

Instant load taking. It may happen that instant load is needed from the engine – only it cannot respond quickly enough, or the instant load will strain the engine which means higher maintenance costs later. Instead of straining the engine, the EMS can bring the battery in to take the load until the engine has ramped up. Because the battery is always on, it will deliver full power in milliseconds.

Cold system start-up. The ship will start with the power stored in the vessel battery. It is ready to go right away because it will not have to wait for the engines to warm up.

Peak shaving. When there is load fluctuation, the energy storage system will complement the engines. The engines can continue operating at stable load.

Power boost. The propulsion system will get a power boost when both the engines and the batteries supply power at the same time.

Automatic power backup. Emergency backup algorithms in the EMS control the built-in backup power sources. The EMS will bring them into use automatically when needed. This makes the ship’s operations safer also in exceptional situations.

Charging. The EMS controls that the battery will charge at its allowed C rate. This safeguards the lifetime of the battery.

Operating modes adapted to real‑world profiles

Wärtsilä HY supports many different operating modes and automatically adapts propulsion and power generation to different operational scenarios, from zero emission manoeuvring to full power transit.

Wärtsilä HY - the future of propulsion

Wärtsilä HY includes many built-in redundancies. They make it possible for the engine to operate close to its optimum design point – much better than in a conventional solution. Because the engines operate optimally, there are less emissions.

Even when the load on the engines varies, the EMS can optimise their energy supply. This saves fuel and improves the overall performance of the vessel.

Wärtsilä HY has proven to deliver up to 25% annual fuel savings.*

* The actual figure depends on vessel type and its operating profile.

Why choose hybrid?

- Lower fuel consumption and operating costs

- Compliance with EU ETS, CII, and FuelEU Maritime requirements

- Improved vessel performance and reliability

Proven across ferries, tugs, and merchant ships, Wärtsilä HY works for both newbuilds and retrofits. Its adaptable technology will improve operational efficiency and keep your vessel ready for the future.

Why Wärtsilä HY makes business sense

Choosing Wärtsilä HY can bring long-term operational and financial advantages for your fleet. For ship owners and executives, hybrid propulsion delivers measurable impact where it matters most.

Lower fuel and operating costs

By keeping engines at optimal load and using stored energy for peak shaving and low-speed operations, Wärtsilä HY saves fuel and reduces maintenance needs. This saves money over the vessel’s lifetime.

Compliance – not complexity

Hybrid systems help you stay ahead of tightening regulations. Optimised energy use helps reduce EU ETS related costs, improves CII ratings, and positions your vessel for FuelEU Maritime requirements without major design compromises.

Future-ready investment

Hybrid propulsion adds flexibility for evolving energy strategies. Whether integrating shore power, alternative fuels, or new battery technologies, Wärtsilä HY gives you a platform that will adapt to changes.

Proven performance

From ferries to merchant ships, Wärtsilä HY has delivered real-world savings and reliability. More than 1000 Wärtsilä PTO systems have been installed globally. Explore our case studies to see how operators are achieving benefits today.

The Wärtsilä HY is a market-leading hybrid marine solution, available for newbuilds and as a retrofit for existing vessels. Watch the video to see how some of our customers have benefited from Wärtsilä HY.

Configurations and integration options

Wärtsilä HY is available in configurations that match your vessel and operating profile: diesel‑mechanical with PTO/PTI/PTH, diesel‑electric with a DC hub, and shore power/charging integration. The EMS coordinates engines, electric machines, and the ESS so you get the right balance of power, redundancy, and efficiency.

Hybrid-mechanical CPP

The hybrid-mechanical Controlled Pitch Propeller is teamed with energy storage and shore connection. The power is provided by alternative fuels. The resulting set-up integrates the propulsion system and electrical distribution.

Hybrid-electric FPP

The hybrid-electric Fixed Pitch Propeller teamed with energy storage and shore connection. The power is generated from alternative fuels. This set up is suitable for a direct-driven FPP with large, permanent magnet motors.

Battery options

Three types of batteries used in automotive and energy markets are suitable for marine use:

- NMC (Nickel-Mangan-Cobalt)

- LFP (Lithium-Ferro-Phosphat)

- LTO (Lithium-Titan-Oxid)

All three have their strengths and weaknesses. Wärtsilä experts will select the most suitable type for each vessel application – in the same way they select the other electrical components such as power drives, generators, motors, and transformers.

There is currently one suitable fuel cell type for marine use: the PEM (Proton-Exchange-Membran) fuel cell. PEM fuel cells are practical for vessels that run on hydrogen fuel. Using a PEM fuel cell together with other alternative fuels will require a reformer, and that will bring the efficiency down to the level of a regular combustion engine, bringing no benefits.

The Solid-Oxide Fuel Cell (SOFC) technology is under development for marine applications. This is a promising technology because it will be able to use alternative fuels like methanol and ammonia.

Zero-emission configuration for hybrid ferries

Wärtsilä HY with:

- Diesel mechanic propulsion

- Two main propellers

- Stern thrusters

- Rapid, wireless charging of the energy storage system

Estimated payback time

Around four years (depending on the price levels of fuel and shore power)

Benefits

- Communities near ports as well as passengers will appreciate silent, smokeless operation

- Saves fuel and reduces need for maintenance

- Excellent manoeuvring performance

Containerised solution for hybrid bulkers

Wärtsilä HY Module for Bulkers is a compact, containerised solution including an energy storage system. Its EMS will optimise the power production and consumption onboard. For example, is possible to integrate extra sources of energy such as solar panels into the EMS. The extra energy can then be fed into the grid as auxiliary power.

Place the container on deck and you will save space. Installation will also be possible without drydocking.

This hybrid marine solution can cut your vessel’s emissions by up to 4%, which helps you stay compliant with regulations.

Related reading:

Download the HY Module for Bulkers leaflet

Open page Short sea shipping: Newbuild and retrofit solutions to learn how newbuild bulkers can navigate their decarbonisation challenges.

Optimal performance for your hybrid system

To meet your evolving needs, Wärtsilä’s field service can support you no matter where your assets are located, helping you achieve significant savings in operational costs. Take a look at the services portfolio to see how we can assist you.

Keeping your hybrid power system in top condition is essential, and Wärtsilä is here to help. By partnering with us through a Lifecycle Agreement, our experts will assist you in planning, preparing, and executing maintenance.

Our dedicated team ensures seamless operations, starting with meticulous maintenance planning. We coordinate spare parts and ensure a skilled maintenance workforce is available to perform the work with top quality. With AI-powered solutions and predictive analyses, combined with expert knowledge, we ensure the optimal performance of your vessel.

A Lifecycle Agreement with Wärtsilä provides true peace of mind, allowing you to focus on your core operations while we take care of the rest. Discover more about how we can support you.

Where HY pays back

Wärtsilä will configure and set up the hybrid propulsion system according to each vessel’s operating profile. Different vessels can benefit, including:

- ropax ferries

- ferries

- shuttle tankers

- platform supply vessels (PSVs)

- tugs

- mini-bulkers

- bunker vessels

- PCTCs (pure car and truck carriers)

- fishing boats.

Finnlines’ new RoPax vessels

- Integrated hybrid solution

Benefits

- Fuel savings

- Lower CO2 emissions at sea

- Zero emissions at berth

Aasen’s new bulk carriers

- Integrated Wärtsilä HY system

Benefit

- 50% fuel and emissions savings per tonne transported.

Misje rederi’s new bulk carrier

- Complete hybrid system

Benefit

- Around 40% fuel savings compared with current vessels in Misje Rederi’s fleet.

Proven results

Resources

- Insights article: “Four successful ways to electrify mechanical propulsion – from basic to brilliant”

- Insights article: “Ship to shore power: 5 exciting reasons why it’s time to invest”

- Insights article: “Hybrid ships: a surprising reason they are such an excellent idea”

Could a hybrid solution benefit your vessel?

This white paper reveals real-world cases examples that prove the amazing benefits of hybrid. It will help you decide if hybrid is a good choice for you.

Discover a clear pathway to greater fuel efficiency, lower operational costs and a more sustainable vessel.

Hybrid solutions offer many ways to reduce emissions

Hybrid ships offer many ways to reduce greenhouse gas emissions. You will find four of them in a fascinating eBook “51 great ways the maritime industry could cut its greenhouse gas emissions”. Learn more:

Latest news related to hybrid marine

Frequently asked questions

Ready to design your hybrid propulsion roadmap?

Share your vessel’s operating profile and your goals, and our experts will prepare a tailored feasibility assessment. This assessment will quantifiy fuel and emissions savings, EU ETS cost impact, FuelEU alignment, and the options available to you.

Parts of this page were written with the help of AI. A human expert has verified the contents.