Short sea shipping: Newbuild and retrofit solutions for small merchant vessels

Fleet renewal is becoming essential in today’s evolving small merchant vessel market. Many vessels are approaching the end of their operational life, and owners must now find flexible, future-ready solutions to meet tightening IMO and regional decarbonisation targets.

Wärtsilä supports small merchant ship owners commissioning new vessels – and the designers shaping them – with integrated propulsion and energy solutions that balance performance, compliance, and cost-efficiency.

Whether you're planning a newbuild or considering upgrades, Wärtsilä is your strategic partner for small merchant vessels.

How to save big on fuel? An integrated design approach will help

It’s important to consider the vessel’s drive train, energy flows, and behaviour as a whole. A successful integration of the propulsion system into vessel design can bring great results – saving big on fuel. Watch this 2-minute video to learn more:

Popular solutions for coastal tankers

Tanker vessels operating on short sea routes must meet a range of operational requirements. They may be chartered on short-term agreements with different voyage distances, load conditions and sailing speeds.

It is critical to optimise a coastal tanker vessel’s CAPEX and OPEX to secure its competitiveness and profitability.

Vessel type: Coastal tankers

Typical size range: 3,000–15,000 dwt

Most optimal solutions:

- Hybrid propulsion system (Engine + PTO/PTI + Battery ESS + EMS): Ensures redundancy, flexible operation, and zero-emission port manoeuvering.

- Fuel-flexible medium-speed engine (such as Wärtsilä 25): Ready for LNG and ammonia, future-proof for decarbonisation.

- Controllable-Pitch Propeller (CPP) system with advanced rudder: Enhances manoeuvrability and efficiency across variable load conditions.

Popular solutions for feeder container vessels

Feeder vessels are typically small container vessels that transport containers from smaller hub ports to larger regional terminals. Compared to other vessel types in the short sea shipping sector, feeders operate more predictable routes, matching the mainline traffic between the hubs they serve.

For feeder vessels, optimising OPEX is the key to profitable and competitive operations.

Vessel type: Feeder container vessels

Typical size range: 500–3,000 TEU

Most optimal solutions:

- Hybrid-electric propulsion with battery peak shaving: Optimizes fuel use and handles reefer load spikes.

- Dual-fuel engine (LNG-ready) with NextDF tech: Minimizes emissions and methane slip; ideal for EU-regulated waters.

- Energy saving technologies (For example EnergoFlow and EnergoProFin): Improve propulsive efficiency and reduce fuel consumption.

Popular solutions for general cargo vessels and coastal bulkers

General cargo vessels and short sea bulker vessels must meet a wide range of operational requirements. They can be chartered on short-term agreements, with highly variable voyage distances, loading conditions and sailing speeds.

Optimising vessel CAPEX and OPEX are crucial to securing the profitability and competitiveness for general cargo vessels and coastal bulkers.

Vessel type: General cargo vessels

Typical size range: 3,000–30,000 dwt

Vessel type: Coastal bulker

Typical size range: 3,000–30,000 dwt

Most optimal solutions:

- Modular diesel-electric or hybrid propulsion system: Adaptable to varied cargo loads and voyage profiles; supports electric unloading.

- Fuel-flexible engine platform (Wärtsilä 25 or Wärtsilä 31, for example): Scalable power and future fuel compatibility for long-term compliance.

- GATE RUDDERTM or optimized CPP + Nozzle: Improves manoeuverability and fuel efficiency, especially in shallow/coastal operations.

- Wärtsilä EcoControl: Saves fuel because it seeks and combines the optimal propeller pitch with the optimal engine loading.

Newbuild solutions for small merchant vessel owners

When you seek reliability, high manoeuvrability and low or even zero-emission operations for your small merchant vessel, choose a partner such as Wärtsilä to deliver integrated solutions tailored to your needs.

Choose a future-proof investment

- Fuel efficiency, operational efficiency, emissions compliance, and lifecycle cost control

- Fuel flexibility and digital readiness

- Integration of propulsion, energy, and automation systems: designed to work optimally together

Regulatory and market context

Because the maritime transition toward sustainability is accelerating, the short sea shipping segment is facing a landscape of tightening regulations and shifting market expectations.

In the European Union: EU Emissions Trading System (EU ETS) and FuelEU Maritime are redefining compliance.

Globally: Benchmarks like EEXI and CII mean that even relatively young vessels must be evaluated to ensure continued operational eligibility and competitiveness. IMO’s Net-Zero Framework lays a solid foundation for marine decarbonisation towards and 2050.

In the market context: There is growing pressure from cargo owners, financiers, and charterers, who increasingly favour vessels with strong environmental credentials.

How to deal with the regulatory and market pressures

Newbuilds designed with integrated decarbonisation technologies, flexible power train, and digital capabilities are best positioned to meet both regulatory and client demands.

Existing vessels can consider strategic retrofits such as hybridisation, engine upgrades, and compliance-driven modifications.

Lifecycle planning will help owners make informed decisions on investments.

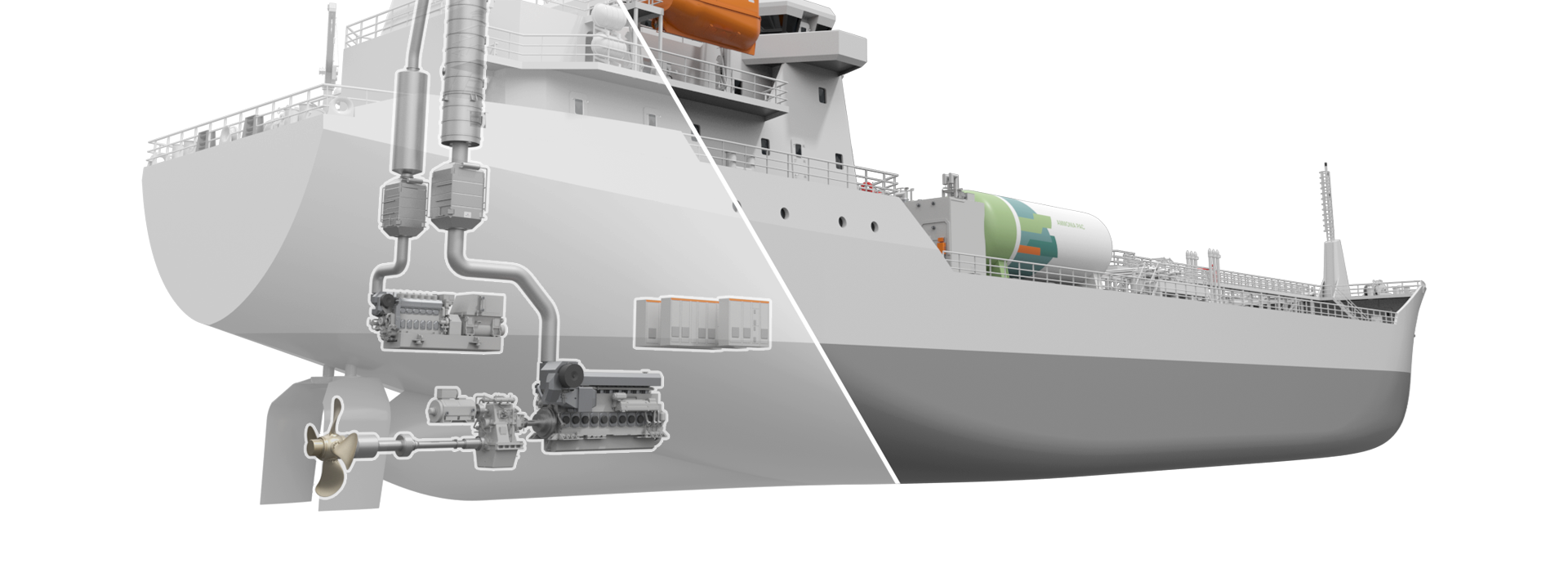

Smart propulsion system for newbuilds

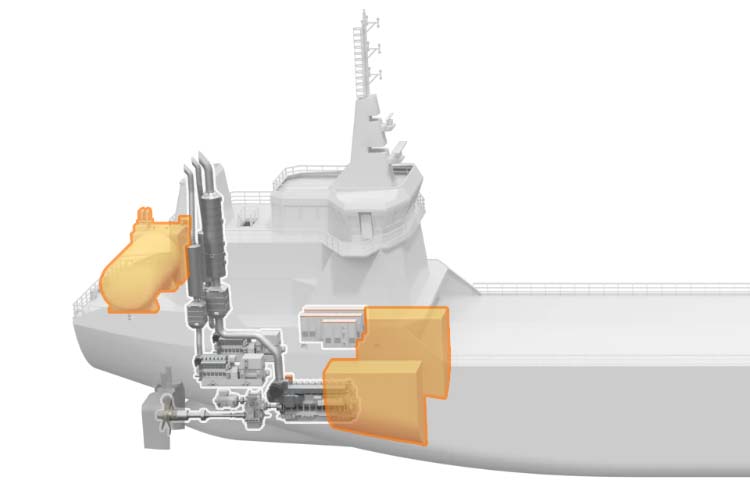

Wärtsilä’s smart propulsion system takes an integrated approach, combining engines, energy storage, propellers, electrical systems, and digital controls into a single, optimised solution. This ensures that the components work optimally together and deliver maximum efficiency, flexibility, and compliance from day one.

This propulsion system is modular and built around a medium-speed engine, controllable-pitch propeller (CPP), power take-off/power take-in (PTO/PTI), energy storage system (ESS), and energy management system (EMS). It can be tailored to your vessel’s operational profile, whether you need silent port operations, fuel savings on variable-speed voyages, or extra power for manoeuvering.

Key benefits:

- Fuel flexibility – Ready for LNG, methanol, and ammonia

- Hybrid-ready – Supports electric modes and peak shaving

- Redundancy and safety – Multiple power sources for critical operations

- Lower emissions – Shore power enables zero-emission port stays and reduced GHG footprint

- Lifecycle efficiency – Designed for long-term compliance and serviceability

This system is ideal for coastal tankers, feeders, and bulkers operating in EU-regulated waters or under charter conditions that demand both performance and adaptability.

Explore the components of Wärtsilä’s smart propulsion system for small

merchant vessels

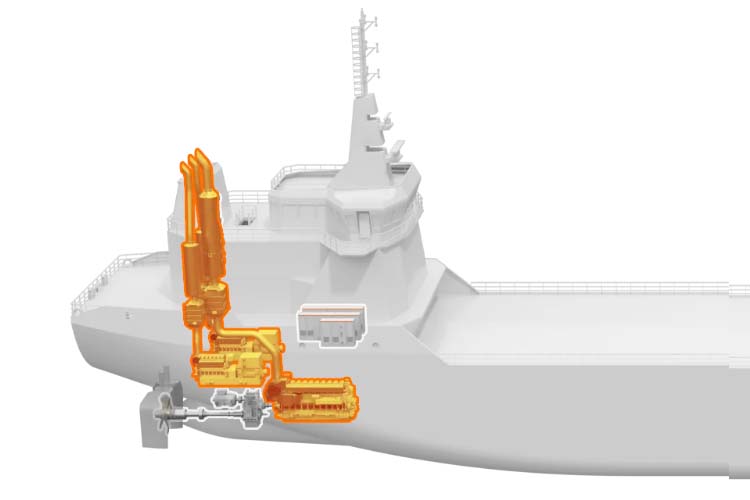

The propulsion equipment consists of

- a controllable pitch propeller (CPP), which ensures flexibility under variable sailing conditions. The main engine is mechanically connected to the CPP through a one-step gearbox with PTO/PTI connection. OPTI design technology improves propeller performance and interaction between the propeller and the hull.

- a bow thruster, which provides improved manoeuvrability

- the Wärtsilä ProTouch propulsion control system offers a user-friendly interface and advanced features such as EcoControl

- GATE RUDDER™ by Wärtsilä will enhance manoeuvrability and efficiency

Equipped with Wärtsilä’s smart propulsion system, your small merchant vessel can enjoy a long service life, meeting the current and future Carbon Intensity Indicator (CII) targets.

Main engine

The Wärtsilä smart propulsion system is powered by a 4-stroke medium-speed engine offering unmatched fuel flexibility. The engine can be installed on resilient mountings to reduce vibrations and underwater radiated noise. Depending on the selected fuel type, Wärtsilä can supply an optimised combination of exhaust aftertreatment (SCR/Scrubber) and a fuel storage and supply solution

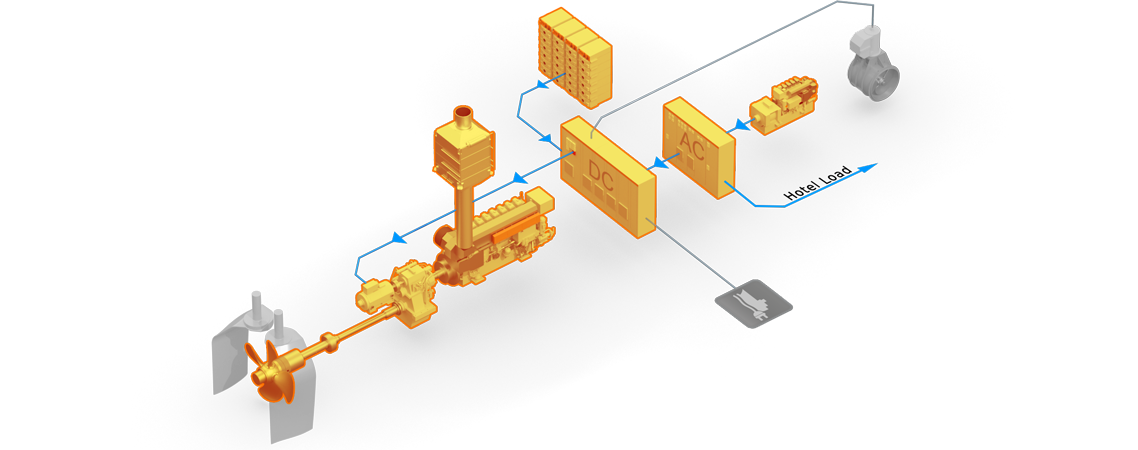

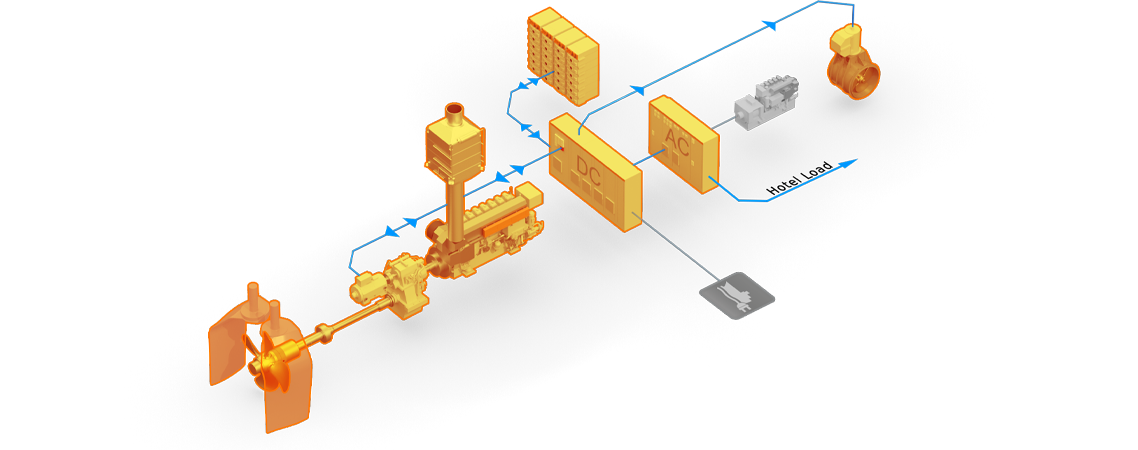

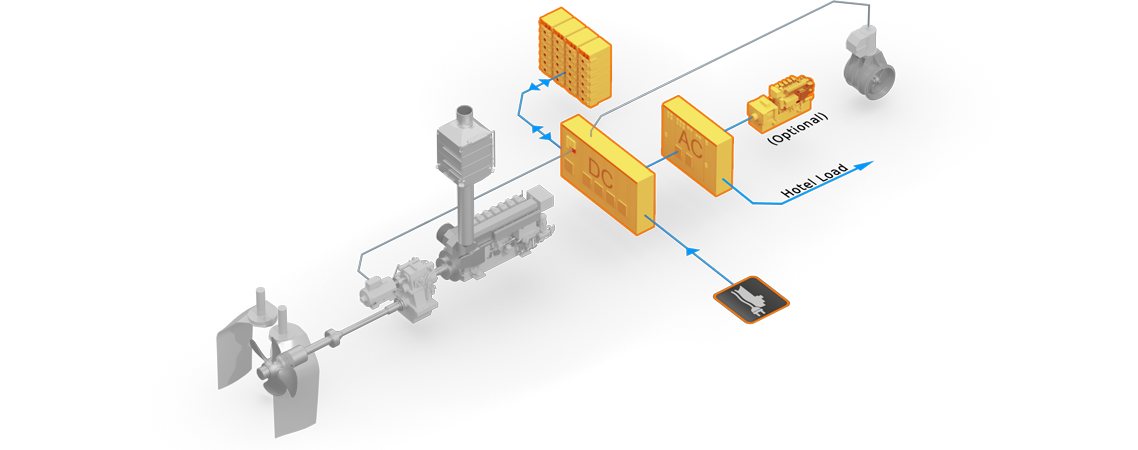

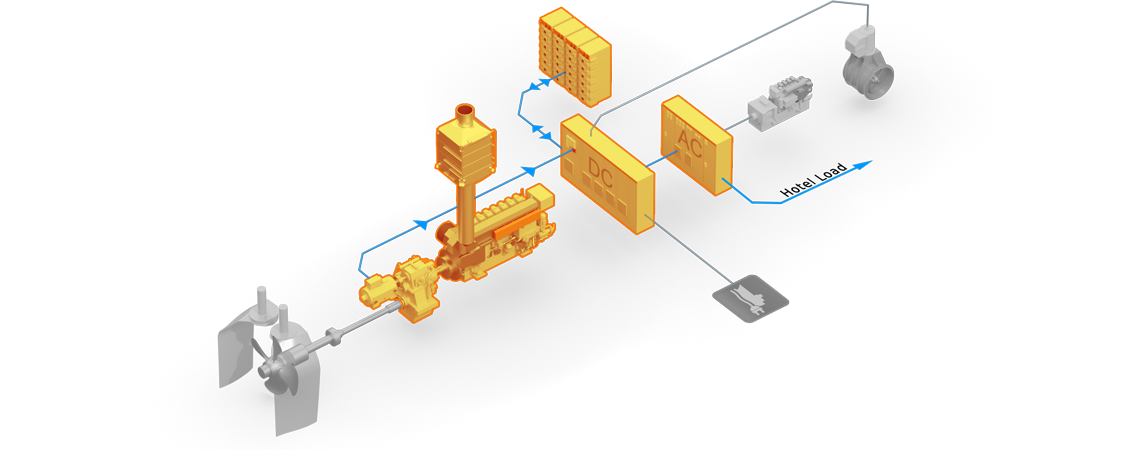

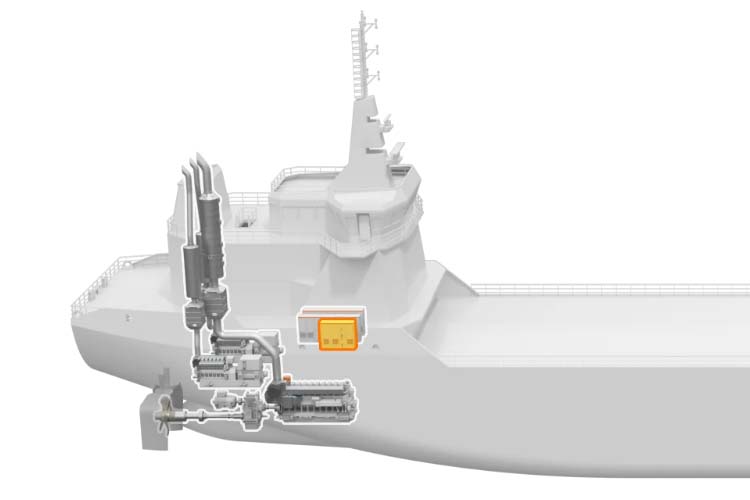

Power conversion

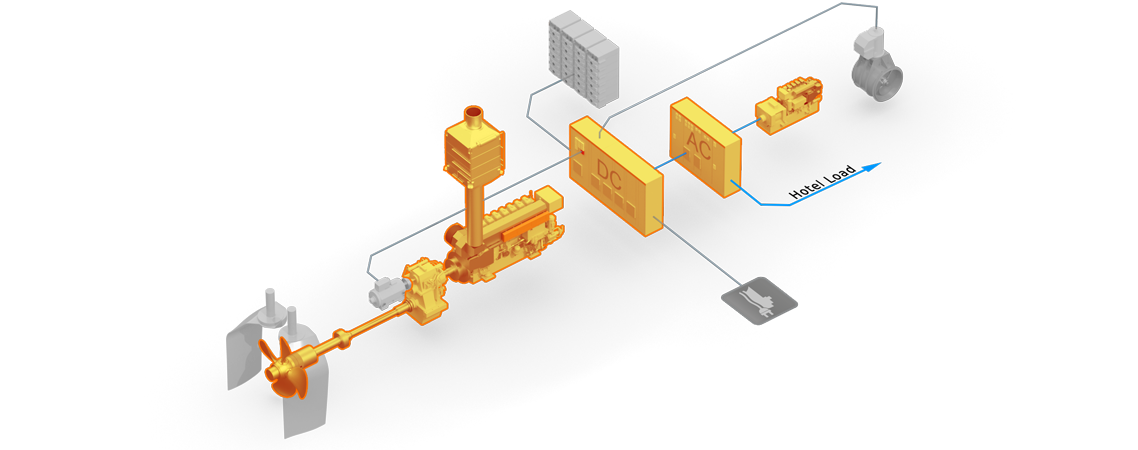

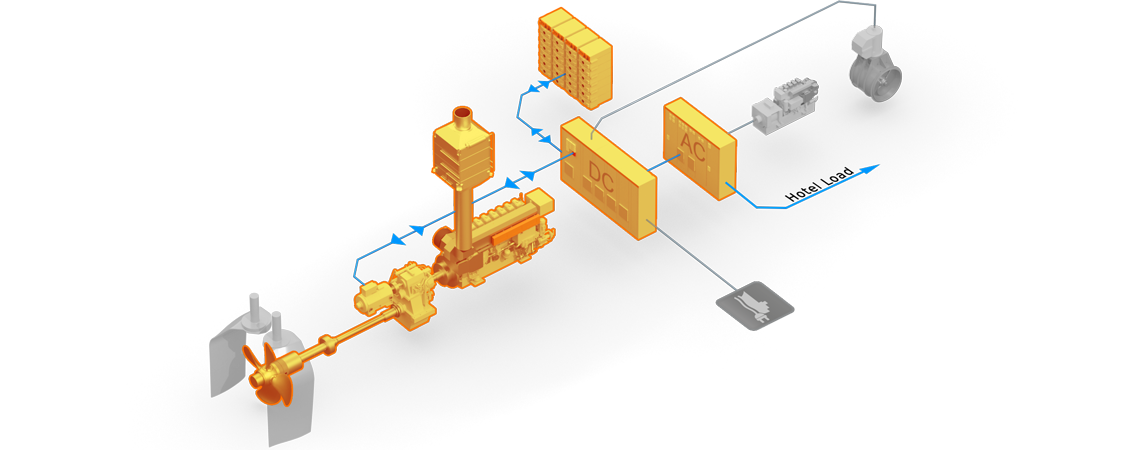

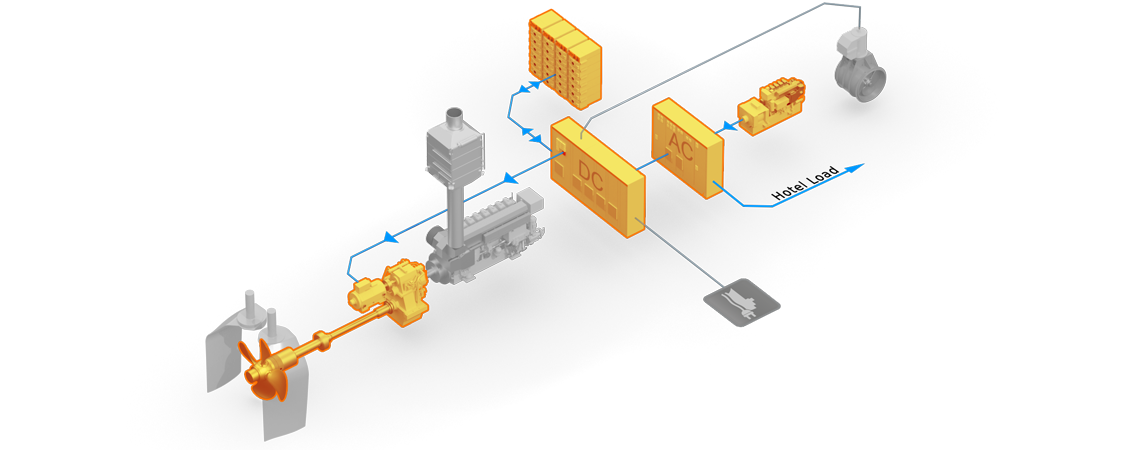

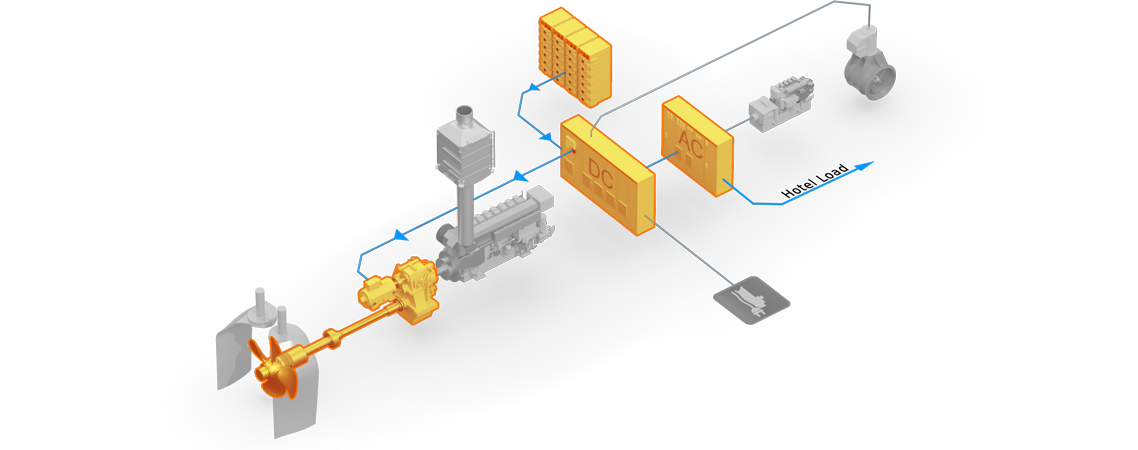

Power conversion onboard is based on an AC configuration with a DC hub. Power is supplied primarily by a variable-speed shaft generator during sailing and by shore connection in port. An auxiliary genset is provided as a backup. The shaft generator can also be used as a motor in PTI/PTH mode.

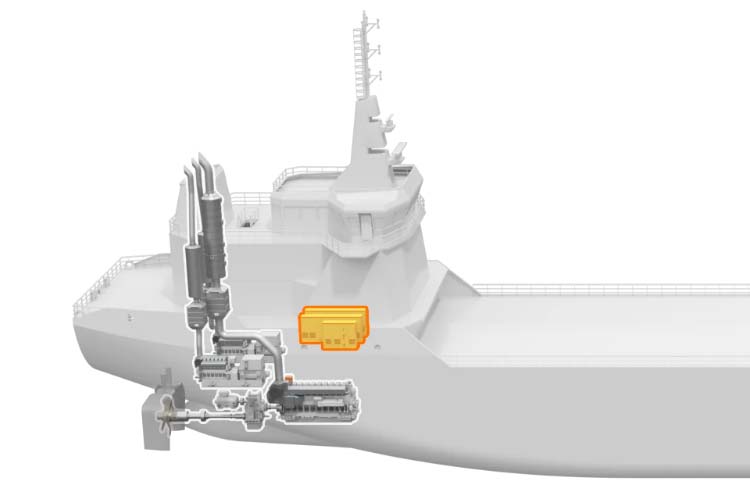

Battery-based ESS

A battery-based ESS is connected to the DC hub to enable the hybrid functionalities of the Wärtsilä smart propulsion system. The energy capacity and power of the marine-certified lithium-Ion batteries are based on the vessel’s operating profile. The DC hub enables easy integration of additional energy sources like solar panels or fuel cells during the lifecycle of the vessel.

Fuel storage and supply

Fuel storage and supply can be adapted to multiple fuels, ranging from conventional liquid fuels and LNG to future fuels such as ammonia or methanol.

System operational modes explained

The integrated Wärtsilä Smart Propulsion System supports multiple operating modes to match the real-world demands of short sea fleets. Whether your vessel is manoeuvering in port, cruising under partial load, or idling at berth, each mode is designed to optimise fuel use, reduce emissions, and enhance reliability.

How Wärtsilä supports the decarbonisation journey of small merchant vessel owners

- Wärtsilä can provide a detailed analysis of propulsion system alternatives. This will include open and transparent benchmarking of the solutions based on parameters such as GHG emissions, CAPEX, OPEX, EEDI, and CII.

- Detailed technical specifications for the scope of supply is included. This supports the integration of the propulsion machinery system into the vessel specification.

- A functional specification describes how the propulsion machinery system alternatives would be integrated. It will also detail their functionalities and operational modes.

The analysis with the technical and functional specifications of the propulsion machinery system helps the owner understand the full potential of the solution.

For the naval architect and ship designer, the analysis helps integrate the propulsion machinery system successfully into the vessel design.

Find a collection of helpful resources: Essential solutions for naval architects and ship designers

Insights on short sea shipping

Why a retrofit can still matter

Certain retrofits can still benefit small merchant vessels that have some lifetime left. For example:

- Engine upgrades for fuel savings

- Compliance retrofits for EEXI/CII

- Retrofit feasibility assessments

- Lifecycle planning and fleet-wide strategies

Customer stories from the short sea shipping segment

See how other small merchant vessels have benefited from solutions provided by Wärtsilä.

Hand-picked press releases

Build smarter, sail smoother: integrated solutions for short sea shipping.

Choosing Wärtsilä means choosing a partner who understands the complexity of short sea operations. Wärtsilä can also delivers power, propulsion, and control solutions that work together in an optimal way.

Whether you're designing a new container feeder, coastal bulker or tanker, or general cargo vessel, Wärtsilä’s integrated approach helps meet emissions targets and reduce fuel costs. You can stay competitive in this changing market.

Take the first simple step toward a smarter vessel: talk to us about your project.

Parts of this page have been written with the help of AI. A human expert has checked all contents for accuracy.