OFFSHORE SUPPORT VESSELS (OSVs)

During the past decades the offshore oil and gas industries have expanded tremendously, which has led to ever increasing demand for offshore support vessels (OSVs) to carry out different operations necessary for floating drilling rigs, as well as moored or fixed production platforms. In order to encompass a more varied and multifunctional role, the facilities installed on board OSVs vessels have been revolutionized, so that they are now amongst the most technically sophisticated vessels afloat.

The OSVs can be divided into a number of types according to the operations they perform: seismic survey ships, platform supply vessels (PSV), anchor handling tugs, anchor handling tug and supply vessels (AHTS), offshore construction vessels (OCV), ROV support vessels, dive support vessels, stand-by vessels, inspection, maintenance and repair vessels (IMR) and variety of combinations of these.

Seismic Survey Ship – A vessel mapping out geological structures in the seabed by firing air guns transmitting sound waves into the bottom of the sea. The echo of the shot is captured by listening devices/hydrophones being towed behind the vessel. Dedicated seismic survey vessels are highly specialised ships. The working decks are enclosed but typically are open at the stern and at a lower level, have the air gun handling system and storage, and at a higher level, they have winches and storage reels for streamers. The ship itself must be capable of accurate track and station keeping and the propulsion system must have low radiated noise and minimal propeller induced noise to avoid interference with the survey equipment.

See also Seismic Ships.

Platform Supply Vessel (PSV) – The PSV is designed for supplying offshore drilling rigs and production platforms with necessary equipment, stores and drilling consumables. These are typically cement, baryte and bentonite transported as dry powders; drill water; oil or waterbased liquid mud, methanol and chemicals for specialized operations.

The PSV loads at a shore base. Liquid cargo is carried in double bottom tanks, dry bulk cargoes in special pneumatic pressure tanks, equipment and drill pipes on the aft open deck. At the rig or platform, the liquid and powder cargoes are pumped up or transferred pneumatically while deck cargo is handled by the rig crane.

A typical PSV operating profile shows the vessel spending about 25% of the time in harbour loading and unloading, 40% sailing at a service in the 14-16 knot range and 35 % loading or discharging at sea, often in strong winds, high seas and strong currents.

The greatest dangers to a crewman working on a supply vessel include being washed overboard in bad weather conditions or being harmed – either by the cargo he is handling or by the equipment he is using. See also Platform Supply Vessel VIKING ENERGY.

Anchor Handling Tug Supply Vessel (AHTS) – The AHTS combines a number of functions in a single hull. These include handling the anchors and mooring chains for drilling rigs, towing of rigs and platforms together with subsequent positioning on site, and platform supply duties. The required bollard pull has a powerful influence on the design, since this defines the power need, the propeller size, hull shape and depth aft to give the necessary propeller immersion. Hull beam and shape shall give good stability, particularly when heavy moorings and anchors are suspended from the stern. Anchor handling requires high power, winch capacity, deck space aft, storage bins for rig chains and auxiliary handling equipment. A stern roller is used to ease the passage of wires and anchors over the stern of the vessel during deploying or weighing of the anchor. See also AHTS SIEM PEARL.

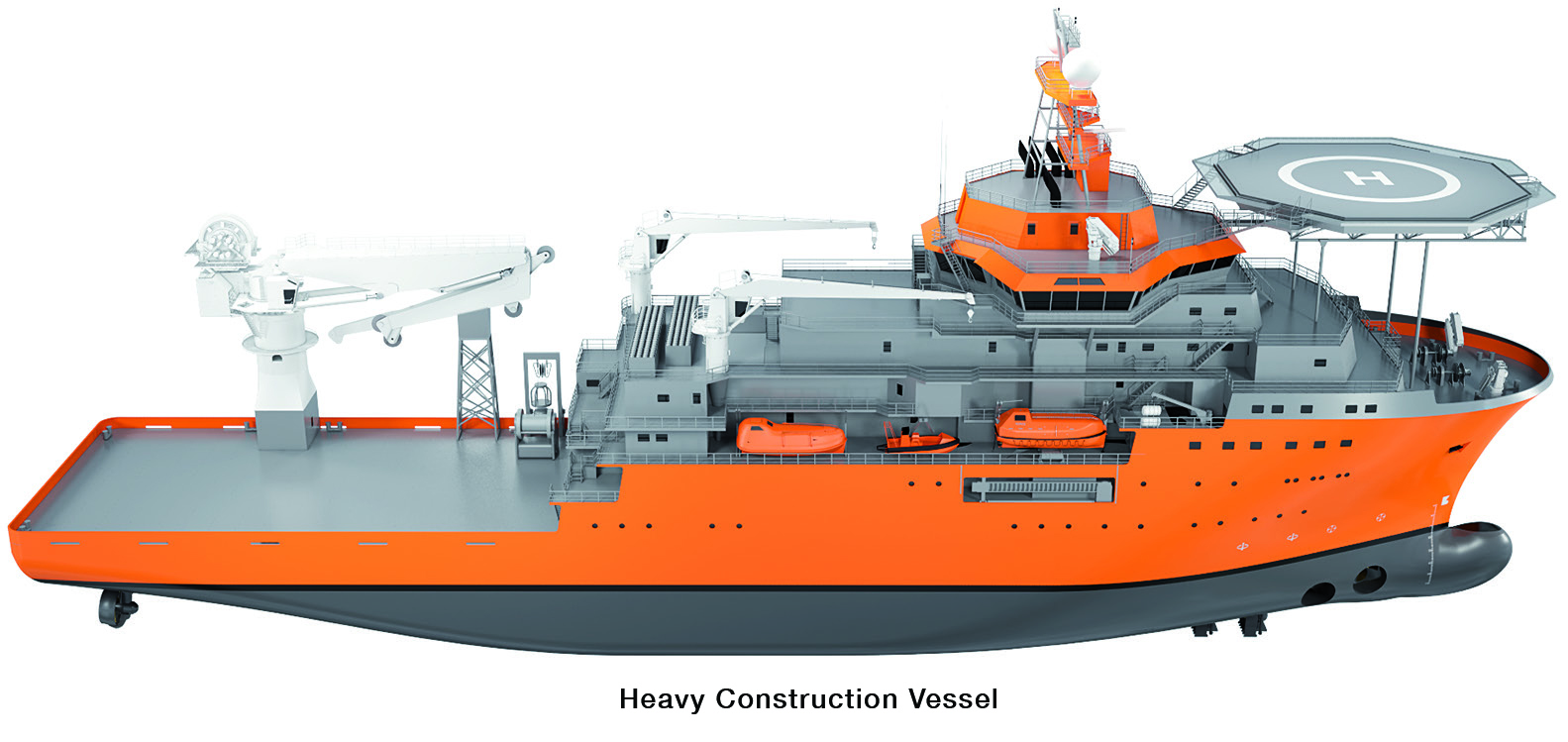

Construction Support Vessels – Dynamically-positioned Class 3 vessels with large unobstructed deck areas, substantial accommodation capacity and significant surface and subsea heavy lift crane capability, able to support surface and subsea construction and installation projects, as well as inspection, repair and maintenance (IRM) programmes. Construction Support Vessels are designed to provide tailored solutions and facilitate larger projects that often require such vessels to remain on location for long periods of time.

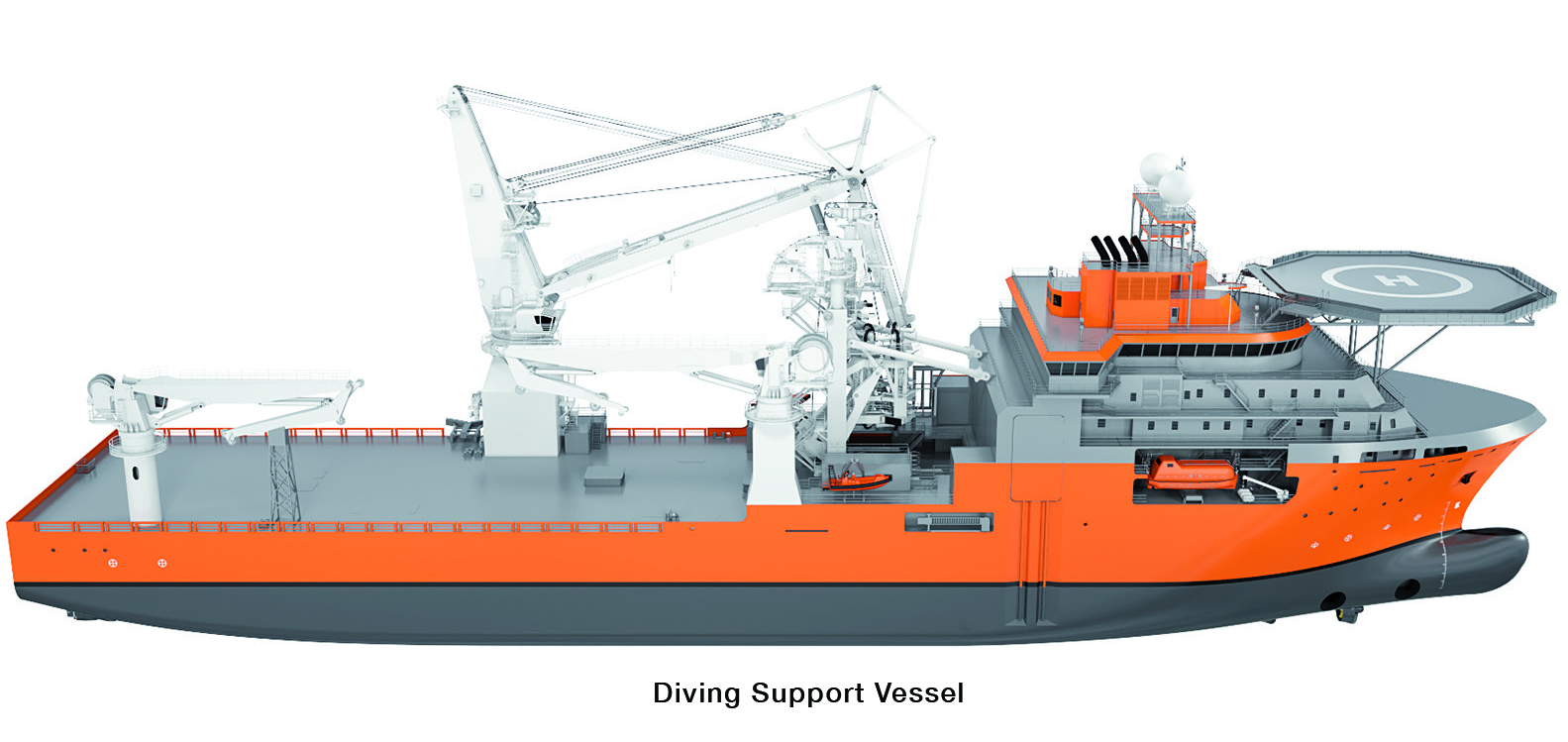

Diving Support Vessel (DSV) – A vessel provided with diving equipment and used for underwater work such as the maintenance and inspection of mobile platforms, pipelines and their connections, well-heads, etc. The DSV is fitted with a moonpool – a hole in the middle of the vessel open to the sea – through which divers, remotely-operated vehicles and other equipment is passed to and from the worksite. The DSV shall maintain an almost exact position over the worksite during diving operations. In order to accomplish this, it shall be provided with a DP3 class positioning system. See also Diving Support Vessel SEVEN ATLANTIC.

Inspection Maintenance and Repair (IMR) Vessel – A dynamically positioned ship-shaped offshore unit provided with equipment for well stimulation or maintenance (e.g. coil tubing). Such vessels are often able to carry out other tasks, such as ROV operations and general supply duties.

ROV Support Vessels – Dynamically Positioned (DP) Vessels from which ROV operations are conducted. ROV Support Vessels are equipped with computer-controlled, precision, position-keeping capabilities with added redundancy features, such as multiple computers, thrusters and reference systems. Such vessels have additional cabins, mess room facilities and Client offices, to comfortably accommodate the Client’s ROV support crews.

Find out more about solutions for Offshore applications