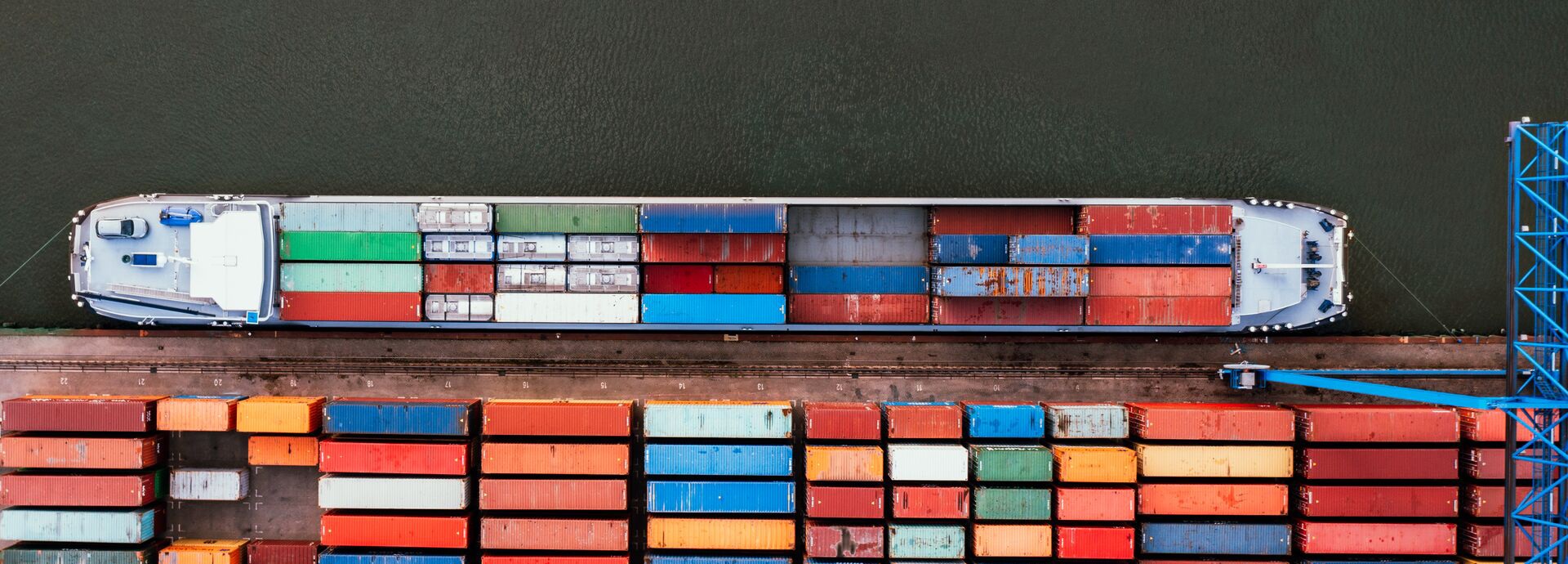

Sustainable container shipping solutions

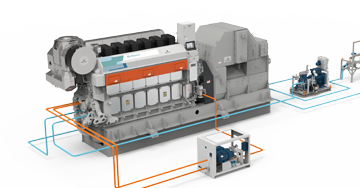

In today's ocean-borne trade, ship owners and operators must optimize asset utilization, meet environmental regulations and safety standards, and enhance vessel performance to stay competitive. At Wärtsilä, we offer smart technology solutions that revolutionize sea transport systems.

With over 185 years of experience, we understand the dynamic nature of the industry and the need to embrace sustainable solutions that contribute to a better and more environmentally friendly future. Our technologies provide increased efficiency, reduced emissions, and enhanced overall performance.

Join us on this journey to a more sustainable future by unlocking the full potential of your vessels. Let Wärtsilä help you drive transformation in the industry and make a difference.

Set sail towards better sustainability: 5 ways to decarbonise container shipping

Thriving global trade is bringing the environmental impact of container shipping into sharp focus. Carbon emissions and air and water pollution are becoming increasingly critical challenges to tackle. Reduce your carbon footprint and overall environmental impact with sustainable container shipping solutions based on decarbonisation innovations.

A strategic approach to reaching GHG emission targets

Lowering GHG emissions in the container shipping industry is a must as cargo ships alone are responsible for 3% of the world’s CO2 emissions. And there are many ways to achieve impressive results in this objective. From LNG conversion and alternative fuels to increasing uptime and optimized route planning, there are so many solutions that can be used and that make economic sense.

Discover more from our infographic to learn how you can benefit.

Download the infographic

We offer complete solutions for reducing your environmental footprint. Move your mouse on the ship to explore examples of our environmental solutions and click the links to find out more.

Offering: Sustainable container shipping solutions

Important insights

Discover these hand-picked webinars and white papers to learn about the many solutions for decarbonised and profitable container operations.

Interesting articles

Discover these hand-picked articles and you will learn more about the many solutions.

Customer stories from the container industry

Discover the benefits others have already gained from choosing Wärtsilä.

Hand-picked press releases

Wärtsilä to install Silverstream’s Air Lubrication System on trial basis to reduce Maersk container ship’s carbon footprint

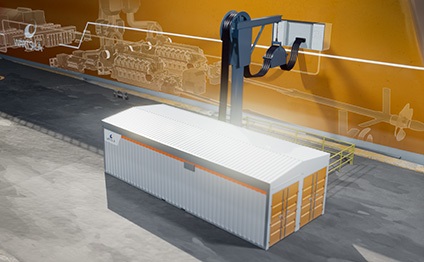

The technology group Wärtsilä, in cooperation with Silverstream Technologies, will install Silverstream’s proprietary Air Lubrication System, the Silverstream® System, on a trial basis on a large container vessel owned by A.P. Moller - Maersk, the world’s largest container vessel operator. The trial will examine possible improvements to the ship’s overall efficiency, focusing on the reduction of fuel consumption and associated emission levels.

The programme will have a special emphasis on the potential application of the System for methanol-fuelled Maersk vessels. The ultimate aim of all three companies is to support efforts to decarbonise shipping operations. The order was placed by Maersk in May 2021.

Silverstream’s Air Lubrication System creates a carpet of microbubbles that coat the entire flat bottom of the vessel. This carpet effectively reduces frictional resistance between the hull and the water. The technology works in all maritime conditions, is not weather dependent, and does not constrain or negatively impact the normal operational profile of the vessel.

“We are delighted that A.P. Moller - Maersk is backing our market leading technology, which is proven to significantly improve operational efficiency and reduce associated greenhouse gas emissions. We also wish to thank Wärtsilä for their collaboration in the delivery of this integrated solution,” says Noah Silberschmidt, Founder & CEO, Silverstream Technologies.

“Everything that we do today inevitably sets the future for coming generations, so we need to act in a positive way to ensure that decarbonising vessel propulsion is an effective priority for the industry. This is a view that is shared by Maersk, a company with whom we have worked closely for many years. Silverstream’s Air Lubrication System is an important stepping stone along this path,” says Bernd Bertram, Vice President, Propulsion, Wärtsilä Marine Power.

The Wärtsilä / Silverstream equipment will be delivered during the second quarter of 2022.

Wärtsilä is an authorised sales and service partner for the System, which is fully integrated within the company’s propulsion portfolio. For newbuild vessels, air lubrication can notably improve compliance with the Energy Efficiency Design Index (EEDI). The System has been proven to reduce fuel burn and associated emissions by five to ten percent, depending on vessel type.

Media contacts for more information on this release:

|

Ms Marit Holmlund-Sund

Mr Rupert Andrews |

Image caption: The Silverstream System creates microbubbles to reduce frictional resistance, thereby lowering fuel consumption. Wärtsilä is an authorised global sales and service partner © Silverstream Technologies

All Wärtsilä releases are available at https://www.wartsila.com/media/news-releases and at http://news.cision.com/wartsila-corporation where also the images can be downloaded.

|

Wärtsilä Marine Power in brief: |

|

Wärtsilä in brief: |

|

Silverstream Technologies in brief: |