Flexicycle™ power plants

Our Flexicycle™ power plants combine the advantages of a flexible simple cycle plant with the high efficiency of a combined cycle plant. Fast load-following power is needed to maintain system reliability, as the share of intermittent renewable energy increases in the power system. The Flexicycle™ solution provides the flexibility needed to facilitate the integration of renewable energy.

As the Flexicycle power plant, supported with lifecycle services, is both agile and highly efficient, it enables competitive performance on both the energy and capacity markets. Depending on the power system, Flexicycle power plants can also be the optimal choice for efficient flexible baseload power generation. The solution is based on a gas, multi-fuel, or liquid fuel engine power plant combined with a steam turbine.

The combination of flexibility and efficiency

The Flexicycle power plant offers a unique combination of flexibility and efficiency. With quick synchronisation and start-up to full engine power in less than five minutes, the Flexicycle plants can be dispatched immediately when an imbalance between supply and demand begins to occur. The solution enables unlimited quick start-up, loading and shut down capabilities without additional costs nor impact on maintenance schedules.

The multi-unit design of engine power plants offers optimised flexibility. High efficiency can be maintained across a wide load range as engine power plant can quickly adjust load by bringing additional engines online or offline to meet changes in demand. In addition this allows optimised plant sizing throughout the lifecycle.

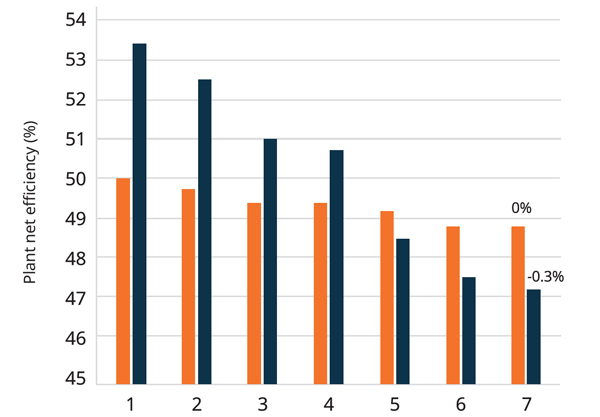

1. ISO conditions sea water cooling

2. Ambient temp 30C

3. Cooling with ACC

4. Gas compression paracitic load

5. Average load 80%

6. Degradation after one year of operation

7. Effects of 100 starts/year

In the Flexicycle concept, the dynamic features of simple cycle combustion engines are maintained as the steam production can be turned on and off individually for each generating set. Additionally, the combined cycle mode, with an optimum efficiency more than 54% (ISO conditions), is ideal for baseload operation and allows for lower carbon emissions per produced kW compared to simple cycle operation.

The Flexicycle power plant solution’s two-in-one characteristic makes it a very competitive solution for handling a grid system’s intermediate load. Thanks to its high combined cycle efficiency, the Flexicycle power plant can also be the optimal choice for flexible baseload generation, depending on the power system’s capacity mix. Features such as fast synchronisation and ramp times, as well as the flexibility of multiple independent units, make these power plants outstandingly well suited to supporting grid systems that require flexibility because of daily load fluctuations, or that have a significant installed base of wind or other non-dispatchable power. It is a perfect solution for both municipal power generation and for the larger utility market.

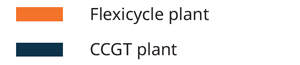

Flexicycle™ technology

In Flexicycle solution, each engine is equipped with a waste heat recovery steam generator. The power plant has a common steam turbine with a condenser. The power plant cooling is typically arranged so that the engines are cooled with closed loop radiators, and the steam cycle with radiators, a cooling tower, raw water or an air cooled condenser. Radiator cooling or air cooled condensers for steam cycle ensures low water consumption of the plant. The fuel flexibility of our solutions enables the choice and utilisation of the most feasible fuels, including natural gas and many other gases, as well as most fuel oils. The customer can also choose to run their plant on multiple fuels.

Flexicycle™ with radiators

The Flexicycle with radiators solution reduces the acquired footprint of the power plant by placing the entire cooling system on the roof. The water consumption of this solution is very low. A Flexicycle power plant with radiators is particularly well suited for cold and moderate climate conditions especially where water consumption is an issue.

Key benefits of Flexicycle™ power plants

HIGH PART LOAD EFFICIENCY AND A WIDE LOAD RANGE

Engines have an exceptional efficiency at part load, which becomes even more valuable in modular plant designs. Also, with Flexicycle plants, the steam production can be turned on and off individually for each generating set to enable flexible operations.

IMMEDIATE DISPATCH WITH NO ADDITIONAL MAINTENANCE COSTS

With short start and shut down times, as well as fast ramp-up capability the Flexicycle plants can be dispatched quickly when required, without impacting maintenance schedules or creating additional costs.

LOWER FUEL CONSUMPTION AND CARBON EMISSIONS

Combined cycle operation extends the plant’s electrical efficiency past 54% (ISO conditions). While fuel consumption and carbon emissions are the same as in simple cycle operation, the relative carbon emissions and fuel consumption per produced kW will be lower in combined cycle operation.

Technology comparison: Engine vs Aero

Curious to find out which is more flexible, reciprocating internal combustion engine or aeroderivative gas turbine? Learn that and more in our technology comparison article series.

References

Would you like to know more?

Contact us

Fill in a contact form and our experts aim to be in contact within 1-2 business days.

Contact us »

Read our brochure

Read our product brochure to get all the details. Download brochure »

Find your local office

News

Wärtsilä completes three EPC projects to Brazil in record time – enables customer to meet vital power supply commitment

The technology group Wärtsilä’s engineering, procurement and construction (EPC) capabilities have been clearly demonstrated with three recent project deliveries to Brazil, which were successfully completed in record time. The orders were placed in Q4, 2021 by TEVISA, Linhares Geração, and Povoação Energia, companies held by funds managed by BTG Pactual Asset Management.

The urgency for completion was the result of the need to meet the required Commercial Operation Date of the power plants as set by the rules of the Reserve Capacity Auction, which was arranged by Brazil’s Ministry of Mines and Energy in October 2021. From contract signing to commencement of commercial operation, the time normally required for each project would be approximately 14 months. In this case, however, Wärtsilä completed all three projects in less than 8 months. Construction of the buildings until commissioning took just three months, and although the equipment was delivered in Q2/2022, all three plants were already in commercial operation by July 2022.

Thanks to Wärtsilä’s ability to meet the strict deadline requirements, the customer has been able to meet fully the Power Purchase Agreement requirements by the Brazilian energy authorities. The electricity produced by these power plants will be fed to the national grid, thereby assuring system reliability.

“We are extremely pleased with Wärtsilä’s efficiency and reliability in having everything completed on time, despite the exceptionally tight schedule. They overcame all the many challenges involved and, in partnership with our team, performed a first-class job. Their reputation in Brazil for being a reliable partner with outstanding EPC capabilities, is well earned,” said Marcelo Oliveira, CEO at TEVISA, Linhares Geração and Povoação Energia.

“Completing these projects within the necessary time-frame required all our experience and know-how. Our existing strong presence in Brazil and understanding of the local needs and practices was of essence in making the fast-track deliveries a success. We utilised increased manpower and extra construction equipment on the sites, and worked in two shifts seven days a week. I think we have sent another clear message to the energy sector regarding Wärtsilä’s capabilities,” commented Jorge Alcaide, Director, Americas South, Wärtsilä Energy.

Among the many difficulties encountered were shipping congestion difficulties resulting from logistic hold-ups and the Covid 19 pandemic, and the war in Ukraine which affected material availability. Wärtsilä was able to meet these challenges, for example, by specifically chartering a vessel to deliver equipment and materials, and using a significant number of air freight deliveries to ensure everything was on site when needed.

The three power plants are part of three separate projects, all in the state of Espirito. The UTE Luiz Oscar Rodrigues de Melo plant and the UTE Povoaҫӑo1 plant are both located in the city Linhares, and the UTE Viana 1 plant in the city of Viana. All three projects feature Wärtsilä 34SG gas engines, in total 16 engines with a combined output of approximately 150 MW, sufficient to provide electricity to some 280,000 households in the region.

To date, Wärtsilä’s track record of EPC deliveries comprises 551 power plants in 109 countries. Their total output is close to 21,720 MW. For each project, specific needs must be met, as well as compliance with regulations, concern for the environment, and the well-being of the local communities affected. Wärtsilä has developed a flexible approach to the varying demands, providing the customer with a single point of contact to ensure efficient project management, while making full use of the latest digital technologies and information systems.

Wärtsilä has been present in Brazil since 1990 and has operations in Rio de Janeiro and Manaus. To date, Wärtsilä has delivered 2.9 GW of power plant capacity in Brazil, of which over 700 MW are currently covered by Wärtsilä long-term service agreements. Wärtsilä has also converted 275 MW of oil-fuelled capacity in the country to run on natural gas.

Learn more:

Wärtsilä engine power plants

Article about Wärtsilä's other recent activities in Brazil: Gas conversions accelerate Brazil’s journey towards decarbonisation

Media contact for more information on this release:

Mirja-Maija Santala

Manager, Marketing & Communications

Wärtsilä Energy

Mob: +358 400 793 827

mirja-maija.santala@wartsila.com

Image1 UTE Povoaҫӑo 1 power plant in Linhares ©Wärtsilä Corporation

Image2 UTE Luiz Oscar Rodrigues de Melo power plant in Linhares ©Wärtsilä Corporation

Image3 UTE Viana 1 power plant in Viana ©Wärtsilä Corporation

All Wärtsilä releases are available at https://www.wartsila.com/media/news-releases and at http://news.cision.com/wartsila-corporation where also the images can be downloaded.

Wärtsilä Energy in brief

Wärtsilä Energy leads the transition towards a 100% renewable energy future. We help our customers in decarbonisation by developing market-leading technologies. These cover future-fuel enabled balancing power plants, hybrid solutions, energy storage and optimisation technology, including the GEMS energy management platform. Wärtsilä Energy’s lifecycle services are designed to increase efficiency, promote reliability and guarantee operational performance. Our track record comprises 76 GW of power plant capacity and 110 energy storage systems delivered to 180 countries around the world.

https://www.wartsila.com/energy

Wärtsilä in brief

Wärtsilä is a global leader in innovative technologies and lifecycle solutions for the marine and energy markets. We emphasise innovation in sustainable technology and services to help our customers continuously improve their environmental and economic performance. Our dedicated and passionate team of 17,000 professionals in more than 200 locations in 68 countries shape the decarbonisation transformation of our industries across the globe. In 2021, Wärtsilä’s net sales totalled EUR 4.8 billion. Wärtsilä is listed on Nasdaq Helsinki.

www.wartsila.com

/huinala.tmb-448x262.png?Culture=en&sfvrsn=20d4c145_1)