Three teams across Wärtsilä are awarded annually in Technology and Innovation, Customer Care, and Sustainability, reflecting the company's dedication to excellence and fostering a culture of innovation. The awards acknowledge and honour the exceptional efforts of teams and individuals who have contributed significantly.

By recognising their achievements, Wärtsilä aims to motivate and inspire others within the company to strive for distinction in their respective fields. Kari Hietanen, Wärtsilä Executive Vice President and sponsor of the award said, “Our competitive edge has always been, and will always be, our ability to innovate, bring new solutions to the market and continuously improve our ways of working. The submissions highlight outstanding initiatives, both small and large scale, within our businesses and processes.”

As energy storage adoption increases, we will see battery facilities edge into urban areas and dense communities and interface with the urban wildland, making fire safety an even greater priority.

This year's notable winner was the Energy Storage and Optimisation (ES&O) team at Wärtsilä Energy. They received the Sustainability Award for ensuring fire safety within the energy storage industry. Launched in 2021, the prize rewards those who have actively worked on a project that improves environmental or social responsibility areas within Wärtsilä's operations or society.

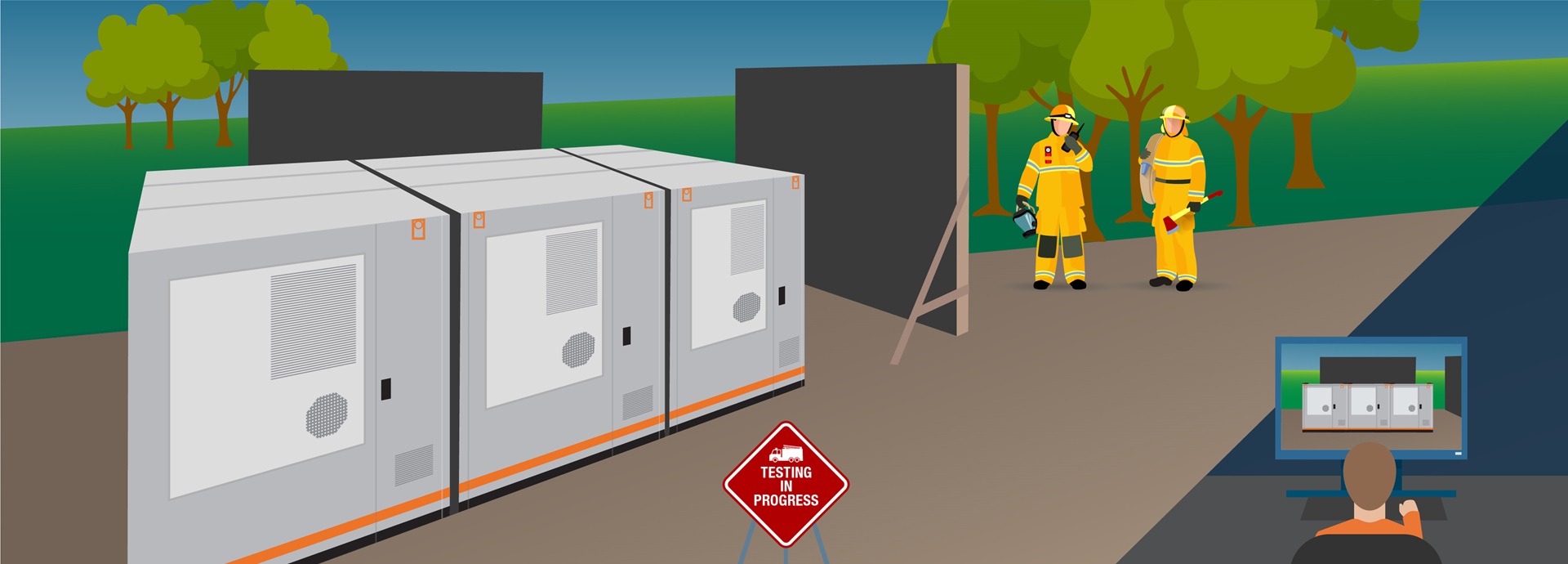

Over the last year alone, the ES&O team has spent almost 9,000 hours on fire safety testing, analysis and reporting to assure stakeholders that its GridSolv Quantum energy storage system (ESS) is safe. To gain insight into what goes into designing an award-winning product, we spoke to Christopher Groves, a Program Manager with the ES&O team and a recipient of the prize.

Evolving Standards, Stronger Safety Features

“Fires at large energy storage facilities have raised serious safety concerns about the industry. With the US aiming to install 100 GW of ESSs by 2030, manufacturers must urgently address these risks, as failure to do so may compel regulators to restrict deployment. This could derail the progress of the energy transition, fail to enhance grid resiliency and leave us exposed to the threat of blackouts and brownouts, which is a temporary drop in the voltage magnitude of an electrical power system.”

Standards and testing methods for energy storage systems are evolving to address the risks of fire incidents. Previously focused on single-cell thermal runaways, recent updates now require manufacturers to also test against multiple-cell thermal runaways, allowing the industry to address the root causes rather than the symptoms. In response, engineers are designing more robust safety features.

Our competitive edge has always been, and will always be, our ability to innovate, bring new solutions to the market and continuously improve our ways of working.

Wärtsilä’s ESS modules, such as those used in GridSolv Quantum, are among the first to pass some of the highest U.S. standards for energy storage safety. “In one instance, a large-scale testing program exceeded the mandatory requirements, setting a new industry standard for fire safety testing.”

Seeing how an ESS reacts in the improbable event of a catastrophic failure provides essential information to stakeholders—from customers to manufacturers and safety officials—about how a system will respond, building confidence in technology and ERP (emergency response plan) best practices. “Even in a worst-case scenario, a fire in a GridSolv Quantum unit would not spread to neighbouring enclosures.”

During the testing process, water samples were also collected to analyse the firefighting water and plume gas emitted by the unit.

“The fire water analysis indicated that the number of contaminants fell above the limits requiring action. As such, the recommendation was to use defensive firefighting or non-intervention tactics in response to an event. Should offensive firefighting be required, a firewater discharge risk assessment should be conducted for ESS facilities. The plume analysis concluded that the smoke from an ESS fire is no worse regarding environmental impact than fires involving normal consumer products.”

The submissions highlight outstanding initiatives, both small and large scale, within our businesses and processes.

Ensuring Robust Fire Safety Measures

To win one of Wärtsilä’s three annual awards and follow in the footsteps of last year’s sustainability award winner, ZEEDS - Zero Emission Energy Distribution at Sea, required a committed team of engineers and managers pursuing advanced research and development around lithium-ion hazards without sacrificing safety.

With thermal stability, a vital step was using Lithium Iron Phosphate (LFP) batteries, emphasised Groves. GridSolv Quantum integrates with LFP batteries, which have a higher flash point and a slower self-heating rate during thermal runaway, making them less prone to fire risk. “Fire safety is an important consideration in our component selection and system design for every project.”

For GridSolv Quantum, there are several safety features, including battery rack protection, rack-level battery management system, integrated fire alarm system, hydrogen sensors, and explosion protection systems, which provide safety on both the battery rack and enclosure levels. The impacted battery rack is also isolated for a safe shut-down in the event of a cell failure.

“Each battery cabinet has a dry pipe fire suppression with a thermally activated nozzle—an aerosol or water-based fire suppression system can be added to the design. Each battery enclosure is also connected to our GEMS Digital Energy Platform, which safely and remotely manages battery state-of-charge and monitors performance on a module level.”

The design also features a central fire safety panel, allowing for the remote shutdown of individual enclosures from a central control room. All ESS sites are designed for remote operations and 24/7 monitoring from a Wärtsilä Customer Expertise Centre.

With the energy storage industry recognising the need for improved communication with local regulators and authorities responsible for enforcing safety codes, efforts are being made to standardise best practices, share knowledge and provide training on emergency preparedness to these stakeholders.

“Collaborating with independent fire safety organisations can enhance the industry’s credibility and facilitate the exchange of important information. As energy storage adoption increases, we will see battery facilities edge into urban areas and dense communities and interface with the urban wildland, making fire safety an even greater priority. These test results solidify Wärtsilä’s position as a market leader in manufacturing safe, compliant battery systems.”

Did you like this? Subscribe to Insights updates!

Once every six weeks, you will get the top picks – the latest and the greatest pieces – from this Insights channel by email.