Flexicycle™ power plants

Our Flexicycle™ power plants combine the advantages of a flexible simple cycle plant with the high efficiency of a combined cycle plant. Fast load-following power is needed to maintain system reliability, as the share of intermittent renewable energy increases in the power system. The Flexicycle™ solution provides the flexibility needed to facilitate the integration of renewable energy.

As the Flexicycle power plant, supported with lifecycle services, is both agile and highly efficient, it enables competitive performance on both the energy and capacity markets. Depending on the power system, Flexicycle power plants can also be the optimal choice for efficient flexible baseload power generation. The solution is based on a gas, multi-fuel, or liquid fuel engine power plant combined with a steam turbine.

The combination of flexibility and efficiency

The Flexicycle power plant offers a unique combination of flexibility and efficiency. With quick synchronisation and start-up to full engine power in less than five minutes, the Flexicycle plants can be dispatched immediately when an imbalance between supply and demand begins to occur. The solution enables unlimited quick start-up, loading and shut down capabilities without additional costs nor impact on maintenance schedules.

The multi-unit design of engine power plants offers optimised flexibility. High efficiency can be maintained across a wide load range as engine power plant can quickly adjust load by bringing additional engines online or offline to meet changes in demand. In addition this allows optimised plant sizing throughout the lifecycle.

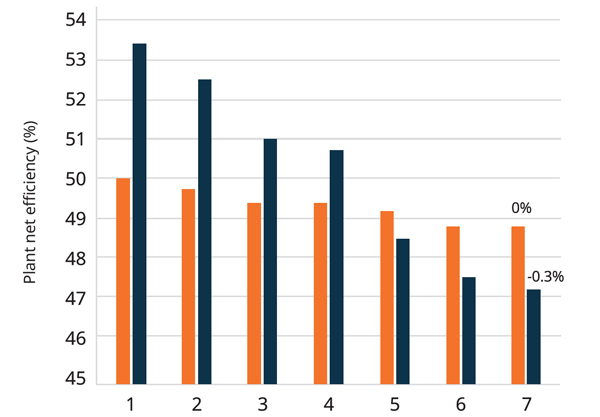

1. ISO conditions sea water cooling

2. Ambient temp 30C

3. Cooling with ACC

4. Gas compression paracitic load

5. Average load 80%

6. Degradation after one year of operation

7. Effects of 100 starts/year

In the Flexicycle concept, the dynamic features of simple cycle combustion engines are maintained as the steam production can be turned on and off individually for each generating set. Additionally, the combined cycle mode, with an optimum efficiency more than 54% (ISO conditions), is ideal for baseload operation and allows for lower carbon emissions per produced kW compared to simple cycle operation.

The Flexicycle power plant solution’s two-in-one characteristic makes it a very competitive solution for handling a grid system’s intermediate load. Thanks to its high combined cycle efficiency, the Flexicycle power plant can also be the optimal choice for flexible baseload generation, depending on the power system’s capacity mix. Features such as fast synchronisation and ramp times, as well as the flexibility of multiple independent units, make these power plants outstandingly well suited to supporting grid systems that require flexibility because of daily load fluctuations, or that have a significant installed base of wind or other non-dispatchable power. It is a perfect solution for both municipal power generation and for the larger utility market.

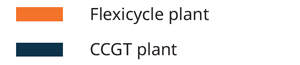

Flexicycle™ technology

In Flexicycle solution, each engine is equipped with a waste heat recovery steam generator. The power plant has a common steam turbine with a condenser. The power plant cooling is typically arranged so that the engines are cooled with closed loop radiators, and the steam cycle with radiators, a cooling tower, raw water or an air cooled condenser. Radiator cooling or air cooled condensers for steam cycle ensures low water consumption of the plant. The fuel flexibility of our solutions enables the choice and utilisation of the most feasible fuels, including natural gas and many other gases, as well as most fuel oils. The customer can also choose to run their plant on multiple fuels.

Flexicycle™ with radiators

The Flexicycle with radiators solution reduces the acquired footprint of the power plant by placing the entire cooling system on the roof. The water consumption of this solution is very low. A Flexicycle power plant with radiators is particularly well suited for cold and moderate climate conditions especially where water consumption is an issue.

Key benefits of Flexicycle™ power plants

High part load efficiency and a wide load range

Engines have an exceptional efficiency at part load, which becomes even more valuable in modular plant designs. Also, with Flexicycle plants, the steam production can be turned on and off individually for each generating set to enable flexible operations.

Immediate dispatch with no additional maintenance costs

With short start and shut down times, as well as fast ramp-up capability the Flexicycle plants can be dispatched quickly when required, without impacting maintenance schedules or creating additional costs.

Lower fuel consumption and carbon emissions

Combined cycle operation extends the plant’s electrical efficiency past 54% (ISO conditions). While fuel consumption and carbon emissions are the same as in simple cycle operation, the relative carbon emissions and fuel consumption per produced kW will be lower in combined cycle operation.

Technology comparison: Engine vs Aero

Curious to find out which is more flexible, reciprocating internal combustion engine or aeroderivative gas turbine? Learn that and more in our technology comparison article series.

References

Would you like to know more?

Contact us

Fill in a contact form and our experts aim to be in contact within 1-2 business days. Contact us »

Read our brochure

Read our product brochure to get all the details. Download brochure »

Find your local office

News

Wärtsilä completes three EPC projects to Brazil in record time – enables customer to meet vital power supply commitment