Sterntube seals, propeller shaft seals

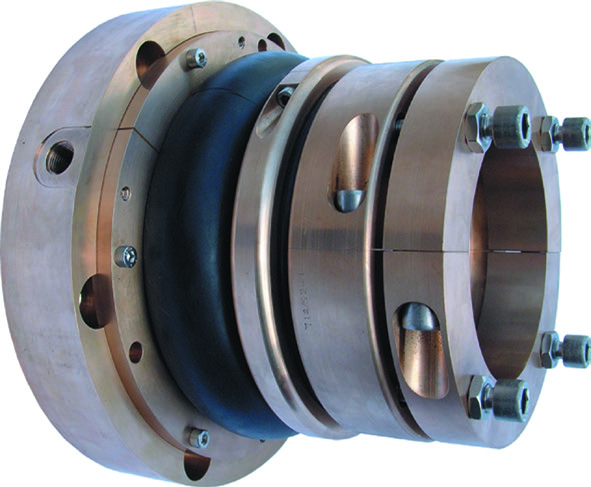

A housing with series of seal rings clamped into position on the bush. Sterntube seals have to perform two separate functions, one is to ensure that water does not enter the engine room, the second one to allow the propeller shaft to rotate as smoothly and freely as possible. Oil lubricated sterntube requires two types of seals, one water/oil seal for the external arrangement (aft seal) and one oil seal for the inboard end (forward seal). Modern sterntube seals are highly-engineered units designed and manufactured to withstand a rigorous working environment for long periods.

- Aft sterntube seal – The function of the aft seal is to prevent leakage of lubricating oil from the sterntube outboard, and to prevent seawater from entering the sterntube and contaminating the lubrication system.

The bush of the after seal is made from a high quality chrome steel resistant to corrosion and wear. In order to extend normal life, an optional ceramic coating can be applied. Viton seal rings are then mandatory. The housing is made from seawater resistant bronze. The lip seals are housed in accurately machined rings and are statically sealed by means of a clamping ring.

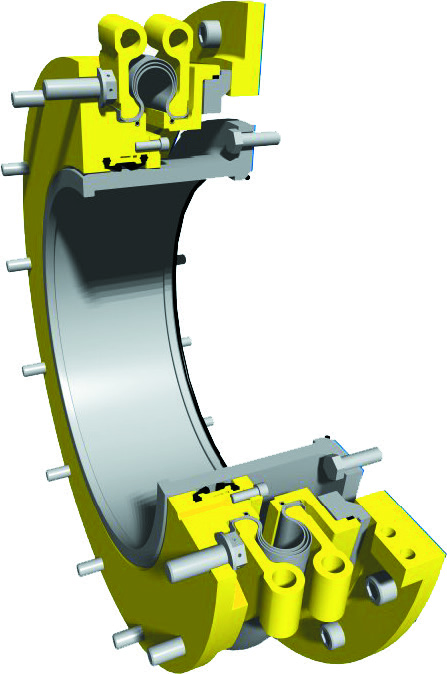

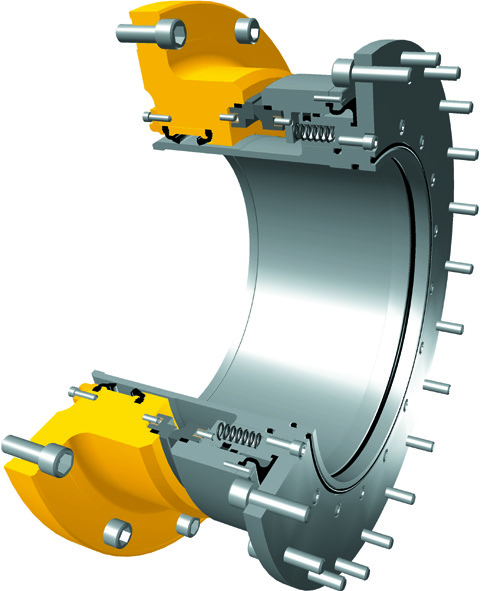

- Split sterntube seals – Split sterntube seals allow the renewal of both lip seal and bush in situ. Split after seals are mostly fitted in cases where the classification society has approved a long interval (10-15 years) between inspections. The split after seal permits inspection of the propeller shaft, particularly the area between the shaft and the flange in installations with CP propellers.