Pump

A machine used to raise liquids from a low level to a higher one, or to provide liquid with an increase in energy enabling it to flow or build up a pressure.

Marine pumps fall into two classes:

1 . Displacement (reciprocating and rotary pumps).

2 . Centrifugal.

Reciprocating and rotary pumps are self-priming and can deal with liquid from a level below the pump. Centrifugal units require to be primed if the liquid is below the pump.

- Axial flow pump – A centrifugal pump which uses a screw propeller to accelerate the liquid axially. It is effectively a propeller in a tube. A large volume flow of liquid at low pressure is produced.

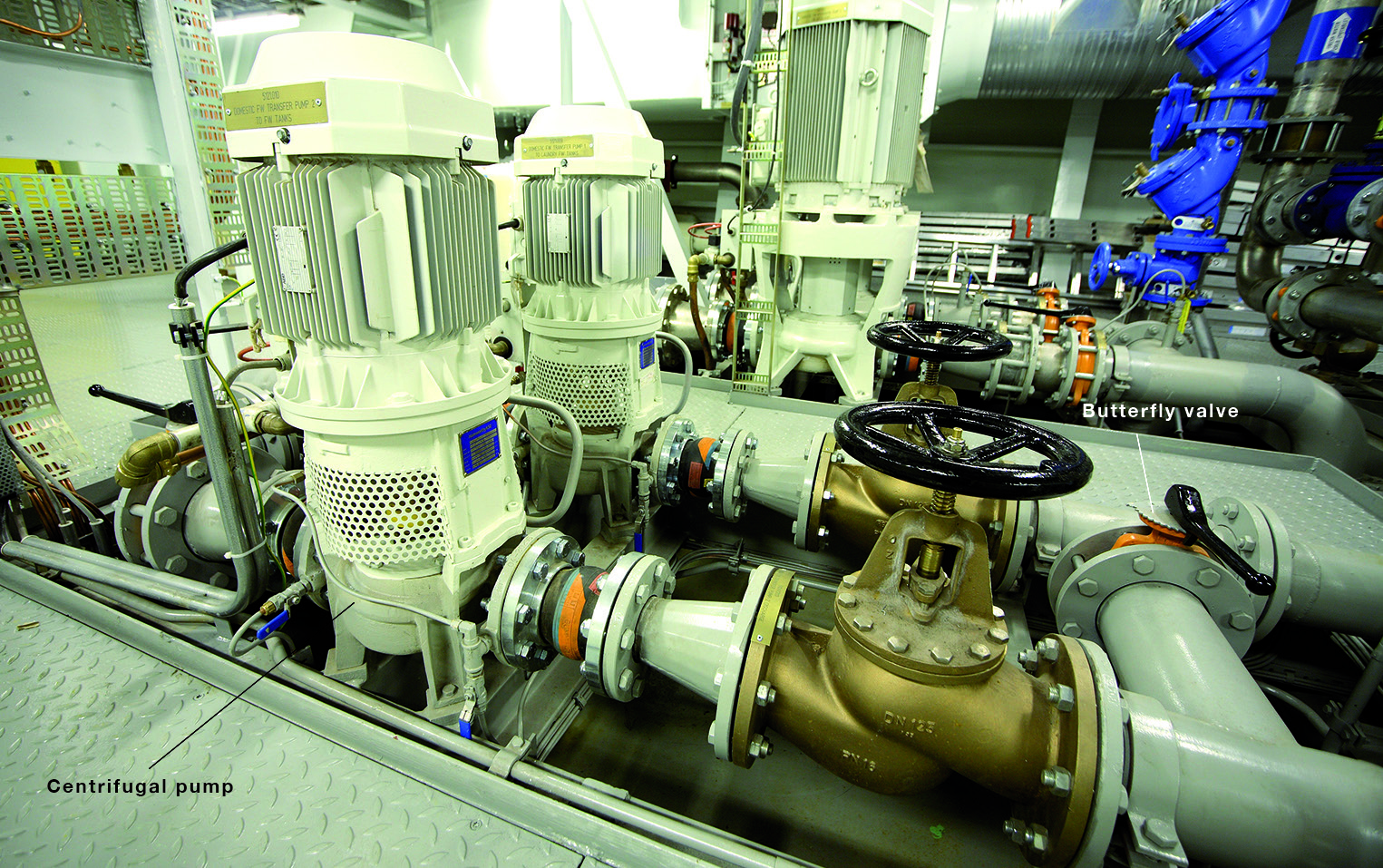

- Centrifugal pump – It develops its pressure as a result of centrifugal force. Liquid enters the centre of the impeller and flows radially out between vanes. Its velocity being increased by the impeller rotation. It escapes through a discharge pipe at the circumference of the casing.

Pumps of this type operate at comparatively high speed usually directly connected to their driver. They are used where large volumes at relatively low pressures are required. They run as fresh or seawater cooling pumps, general service, boiler feed, ballast, firefighting or as lubricating oil pumps. Centrifugal pumps are not self-priming except for some very special designs.

Centrifugal pumps may be classified in several ways. For example, they may be either single-stage or multi-stage. A single-stage pump has only one impeller; a multi-stage pump has two or more impellers housed together in one casing. In a multi-stage pump, each impeller usually acts separately, discharging to the suction of the next- stage impeller.

Centrifugal pumps are also classified as horizontal or vertical ones, depending on the position of the pump shaft. Impellers used in centrifugal pumps may be classified as single-suction or double-suction, depending on the way the liquid enters the eye of the impeller. The single-suction impeller allows liquid to enter the eye from one side only; the double-suction impeller allows liquid to enter the eye from both sides. The doublesuction arrangement has the advantage of balancing the end thrust in one direction with the end thrust in the other direction.

- Displacement pump – A pump operating by the reduction or increase in volume of a space by a mechanical action which physically moves the liquid or gas.

- Reciprocating pump – A pump in which a plunger or piston is mechanically reciprocated in a liquid cylinder. The reciprocating pump has positive pressure characteristics and is used principally to handle small volumes at relatively high pressures. Due to its reciprocating motion and the inertia effect of the parts, speeds are relatively low. This type of pump is self-priming and the delivered capacity is practically constant regardless of discharge pressure.