Oily water separator, bilge water separator

A device used to separate oil from oily water mixtures and from the emulsion. Bilge separators are necessary aboard vessels to prevent discharge of oil overboard while pumping out bilges or while cleaning oil tanks. An oilcontent monitor is provided to measure continuously the oil content of the effluent. If the set limit of the oil content is exceeded, the effluent is automatically recirculated to the collecting tank, or the separator is stopped. Many conventional oily water separators fail to split stable emulsions and remove suspended colloidal particles from the water phase. This often results in equipment malfunction because the separation of oil below 15 ppm is not achieved or because of clogging from excessive solids.

- 15 ppm bilge separator – Any combination of a separator, a coalescer or other means, and also a single unit designed to produce an effluent with oil content not exceeding 15 parts of oil per million parts of water by volume.

Note: According to Resolution MEPC.107(49), a sampling point should be provided in a vertical section of the water effluent piping as close as practicable to the 15 ppm bilge separator. Re-circulating facilities should be provided after and adjacent to the overboard outlet of the stopping device to enable the 15 ppm bilge separator system, including the 15 ppm bilge alarm and the automatic stopping device, to be tested with the overboard discharge closed. One of the main causes of oilywater filtering equipment malfunction is the effect of bilge water containing cleaning agents. Detergent-based cleaning fluids can produce chemically stabilised oil emulsions which cannot be separated on board ship by the gravity alone. The best way to improve the performance of oily bilge water separating equipment is to avoid the use of surfactant-based cleaning materials.

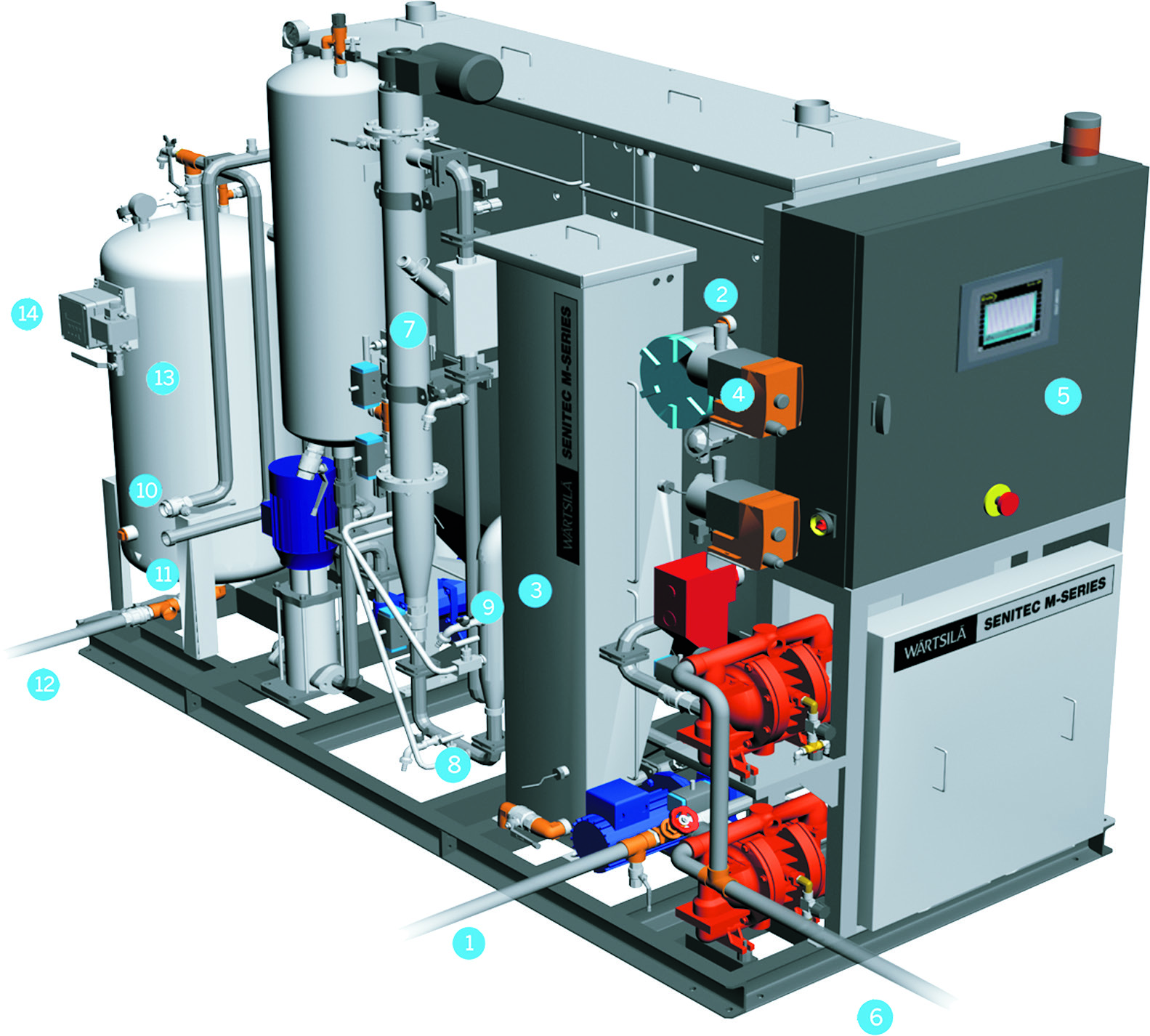

The Wärtsilä Senitec oily water treatment units use optimized emulsion breaking and separation technology that surpasses all existing regulations and guarantees an oil content in the cleaned water of below 5 ppm. In normal operation the actual levels have repeatedly been shown to be as low as 1 ppm, which gives a priceless safety margin to the IMO limit.

1. Bilge water inlet

2. Oil separation stage

3. Emulsion tank

4. Chemical dosing pumps

5. Control panel

6. Oil and solids effluent

7. Chemical stage

8. Dissolved air inlet

9. Inlet to flotation stage

10. Overboard

11. Backwashing water outlet

12. Fresh water inlet (to filter stage)

13. Filter stage

14. Oil monitor

Further reading: Wärtsilä Environment Technologies Product Guide