Bulk carrier, bulker

A vessel designed to carry dry cargo, loaded into the vessel with no containment other than that of the ship, s boundaries, as distinguished from the liquid bulk carrier or tanker. Conventional bulk carrier is constructed with a single deck, single skin, double bottom, hopper side tanks and topside tanks in cargo spaces.

Common to all are intensive deployment and aggressive environmental conditions and port handling procedures, factors that contributed to a disturbing number of casualties in the 1980s and 1990s. 116 bulk carriers have been lost and 618 seafarers have died since 1992 till 2002. The toll stimulated a number of remedial initiatives by classification societies and IMO, targeting the structural areas of risk.

Structural failure nevertheless remains a consistent and significant cause of losses – 14 bulkers were lost with 23 fatalities in 2000, the average age of the ship 20.4 years – while the presence of heavy cargoes featured in many of the casualties. In 2001 four bulkers were identified as total losses and 64 crewmembers lost their lives; The CHRISTOPHER and HONGHAE SANYO went down with all hands. To prevent this situation, the International Association of Classification Societies (IACS) is to introduce the harmonized class notations for bulk carriers:

- BC-I, covering design loading conditions for homogeneous light cargo, heavy grain and ballast.

- BC-II, vessels designed to carry homogeneous heavy cargo.

- BC-III, covering loading conditions for heavy cargo with specified holds empty. The conventional bulk carrier design, with its single side plating between the upper wing tanks and two lower hopper tanks, exposes its vertical framing to the rigors of fatigue, corrosion and mechanical damages. Even a significant increase in the scantling of these members would not offer as much improvement as would be derived from a doublesided alternative design.

Double side skin design eliminates the exposed, damage-prone transverse framing and its end attachments. They protect against cargo–related corrosion and mechanical damage. They allow for better quality surface preparation and coating application. Most importantly, they create much stiffer side structures, effectively eliminating the flexing or fatiguing of the side frame and shell plating connection as occurs in conventional designs. Operators of double side skin bulkers also report noticeable operational improvements, particularly higher discharge rates, simpler cleaning, faster turnarounds and fewer repairs. It must also be remembered that double sides, by themselves, will not eliminate the possibility of loss. Attention must also be paid to freeboard requirements, to the reintroduction of raised forecastles, to strength of vents and deck fittings and to the strength and watertight integrity of hatch covers, together with particular attention to maintenance and coatings.

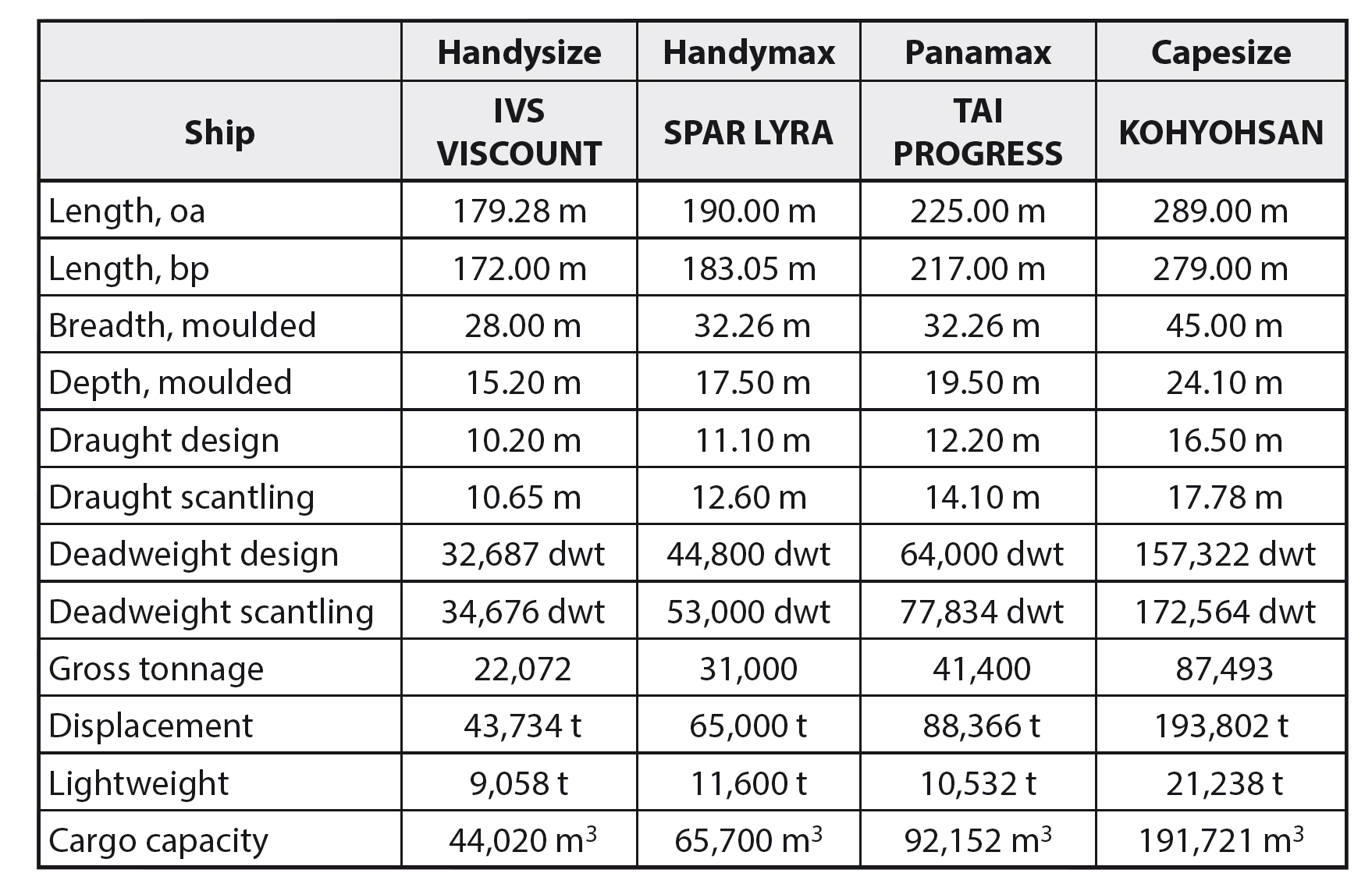

INTERCARGO, subdivides bulk carriers in Handysize, Handymax, Panamax and Capesize according to their deadweight ranges.

- Handysize bulk carriers – Bulkers in the 10,000 – 34,999 dwt capacity range capable of carrying either dry bulk cargoes or industrial consignments packed in units (e.g. bags of sugar or flour, metallurgical products, timber).

- Handymax bulk carriers – Bulkers in the 35,000-49,999 dwt capacity range.

- Panamax bulk carriers – 50,000 – 79,999 dwt bulkers, which can pass through the Panama Canal.

- Capesize bulk carriers – 80,000 – 199,000 dwt bulkers, the size of which obliges them to go round the Capes of Good Hope and Horn.

- Dunkirk-Max – A new “max” design was presented in “Significant Ships of 2001”, named Dunkirk-Max by the builder CSBC; it was marketed as the largest ship, in terms of deadweight and cubic capacity, to meet the specific limitations of the de Gaulle Lock in the port of Dunkirk, France.

See also Bulk carrier EYLUL K.

Further reading: Bulk carriers “Guidelines for Surveys, Assessment and Repair of Hull Structures”, IACS.

IACS Recommendation 46: BULK CARRIERS Guidance and Information on Bulk Cargo

Loading and Discharging to Reduce the Likelihood of Over-stressing the Hull Structure.

Both can be downloaded from www.iacs.org.uk