Converting engines to run on gas

– and beyond

As gas grids expand and emission levels continue to tighten, conversion to natural gas is an increasingly viable alternative for power plants. Wärtsilä engines are flexible and easily adapted to using gas as a primary fuel, helping to cut operational costs and exhaust gas emissions while increasing fuel flexibility. Gas conversion is one key feature in future-proofing power plants, as it enables transition to synthetic, sustainable fuels in the future.

Moving forward with future-proof options

Why consider a gas conversion?

As natural gas is both attractively priced and efficient, converting an existing engine to operate on gas offers significant economic and environmental benefits. Gas also offers you increased operational flexibility as other fuels can still be used if needed. A gas conversion helps to future-proof your plant by allowing you to transition to synthetic fuels at a later date and enables integration of renewable energy sources by providing reliable balancing.

A cost-optimal business move

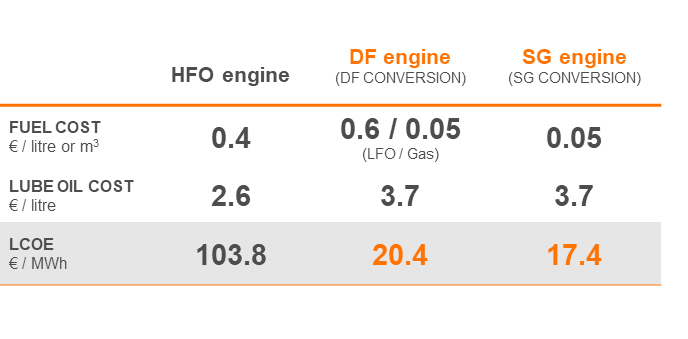

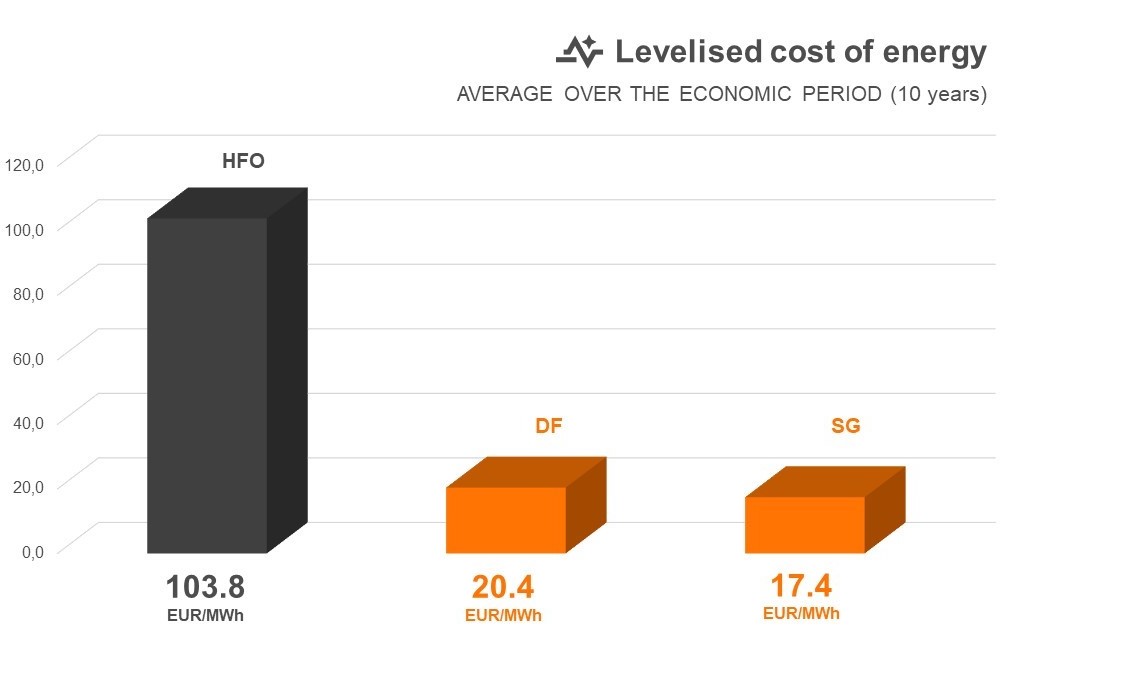

Case example: the impact of fuel type and technology on levelised cost of energy.

The example demonstrates the impact of technology and fuel type on levelised cost of energy. The example is based on a 100 MW power plant, with six W18V46 engines. The actual values are not directly applicable for any power plant, but will depend on several variables and factors.

Reduced power plant emission levels

Case: Delimara gas conversion

Shanghai Electric Power reduced both electricity production costs and emission levels at their Delimara 3 Power Plant in Malta as eight Wärtsilä HFO-fuelled engines were converted to run on natural gas including installation of the new UNIC C3 engine control system. This means a lower heat rate for the engines, increased efficiency, higher power output capacity, and lower emissions, in other words, reduced operational costs.

News

Wärtsilä gas conversion project will accelerate Senegal’s move to cleaner energy production

The technology group Wärtsilä will convert the close to 90 MW Bel-Air power plant in Dakar, Senegal to operate on liquefied natural gas (LNG). The plant, which is owned by Senelec, Senegal’s public utility company, currently operates on heavy fuel oil. The conversion will future-proof the facility as Senegal’s long-term strategy is to lower the carbon footprint of energy production by switching to gas when a domestic supply is available. This project is part of an interim LNG-to-Power ‘bridge’ solution, and is the first ever power plant gas conversion in Senegal. The order with Wärtsilä was booked in Q1 2021.

“Our two main aims were to improve the plant’s environmental profile and to lower the operating costs. By taking advantage of Wärtsilä’s deep experience and strong capabilities in power plant gas conversions, we can achieve both of these goals. At the same time, we are preparing the plant for the country’s future gas supply infrastructure,” said Papa Mademba Biteye, Managing Director of Senelec.

“Future-proofing the customer’s assets to meet the requirements over the lifecycle via a gas conversion is far more cost-effective than building a new plant. It also facilitates the greater use of energy from renewable sources, such as solar and wind, since the converted plant will be able to provide highly flexible, fast-starting baseload power for balancing the grid,” commented Marc Thiriet, Energy Business Director, Africa West, Wärtsilä.

The Bel-Air plant’s existing six Wärtsilä 46 engines will be converted to six Wärtsilä 50DF dual-fuel engines. Wärtsilä’s current operation & maintenance agreement covering the existing engines is being renegotiated in view of the conversion. Wärtsilä’s dual-fuel engine technology allows the use of multiple fuels, providing the option to operate on gas with liquid fuels as back-up.

Besides the engine conversion, the project will cover all aspects to ensure successful operations on gas. Everything from safety to operational reliability are taken into account, with control functions, mechanical auxiliary systems, as well as electrical and automation systems being changed or upgraded as required. As part of the engineering, procurement, and construction contract, Wärtsilä will manage all phases of the project, which is expected to be completed before the end of 2021.

In addition to the Bel-Air plant, Senelec also has three other Wärtsilä power plants in operation in Senegal. Wärtsilä has a leading position in supplying flexible power generation to West Africa with 4792 MW of capacity installed.

Read more:

Gas conversions for power plants

Lifecycle upgrades for power plants

Wärtsilä Lifecycle solutions

Media contact for more information on this release:

Mirja-Maija Santala

Manager, Marketing & Communications

Wärtsilä Energy

Mob: +358 400 793 827

mirja-maija.santala@wartsila.com

Image1 and 2: Conversion of six Wärtsilä engines to Wärtsilä 50DF dual-fuel engines will enable Senelec to provide highly flexible, fast-starting baseload power from Bel-Air plant for balancing the grid ©Wärtsilä Corporation

Image 3 of the control room: ©Senelec

All Wärtsilä releases are available at https://www.wartsila.com/media/news-releases and at http://news.cision.com/wartsila-corporation where also the images can be downloaded.

Wärtsilä Energy in brief

Wärtsilä Energy leads the transition towards a 100% renewable energy future. We help our customers in decarbonisation by developing market-leading technologies. These cover future-fuel enabled balancing power plants, hybrid solutions, energy storage and optimisation technology, including the GEMS energy management platform. Wärtsilä Energy’s lifecycle services are designed to increase efficiency, promote reliability and guarantee operational performance. Our track record comprises 74 GW of power plant capacity and more than 80 energy storage systems delivered to 180 countries around the world. https://www.wartsila.com/energy

Wärtsilä in brief

Wärtsilä is a global leader in smart technologies and complete lifecycle solutions for the marine and energy markets. By emphasising sustainable innovation, total efficiency and data analytics, Wärtsilä maximises the environmental and economic performance of the vessels and power plants of its customers. In 2019, Wärtsilä’s net sales totalled EUR 5.2 billion with approximately 19,000 employees. The company has operations in over 200 locations in more than 80 countries around the world. Wärtsilä is listed on Nasdaq Helsinki. www.wartsila.com