Converting engines to run on gas

– and beyond

As gas grids expand and emission levels continue to tighten, conversion to natural gas is an increasingly viable alternative for power plants. Wärtsilä engines are flexible and easily adapted to using gas as a primary fuel, helping to cut operational costs and exhaust gas emissions while increasing fuel flexibility. Gas conversion is one key feature in future-proofing power plants, as it enables transition to synthetic, sustainable fuels in the future.

Moving forward with future-proof options

Why consider a gas conversion?

As natural gas is both attractively priced and efficient, converting an existing engine to operate on gas offers significant economic and environmental benefits. Gas also offers you increased operational flexibility as other fuels can still be used if needed. A gas conversion helps to future-proof your plant by allowing you to transition to synthetic fuels at a later date and enables integration of renewable energy sources by providing reliable balancing.

A cost-optimal business move

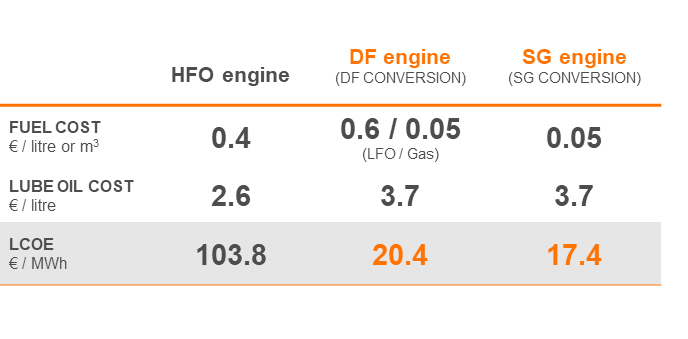

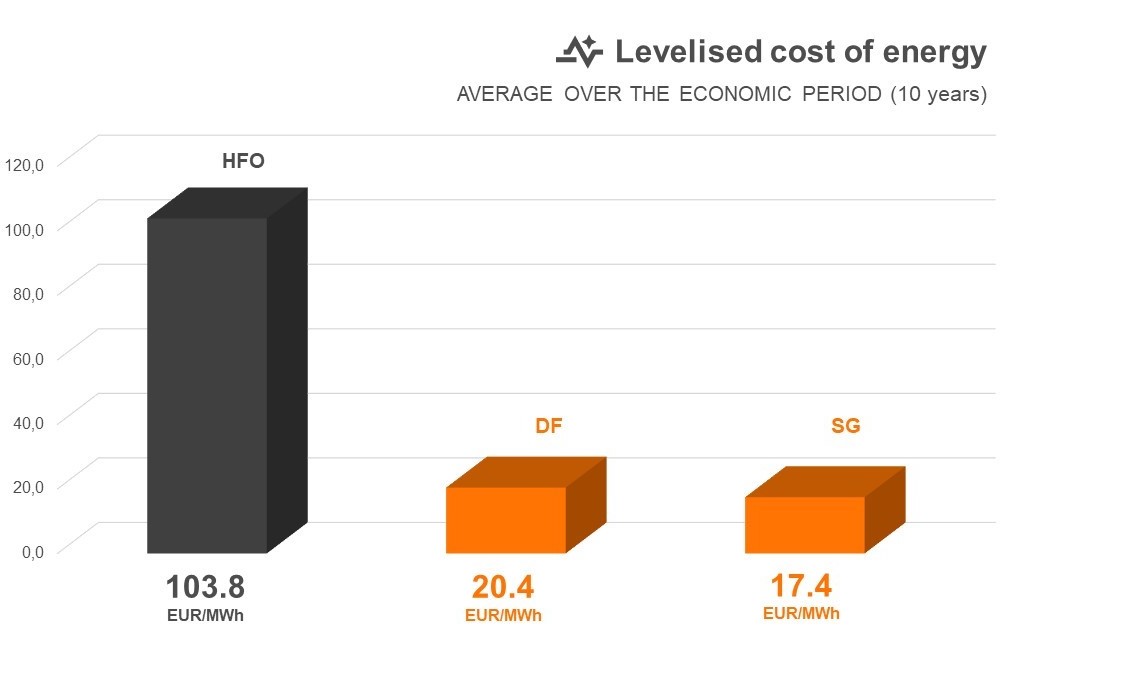

Case example: the impact of fuel type and technology on levelised cost of energy.

The example demonstrates the impact of technology and fuel type on levelised cost of energy. The example is based on a 100 MW power plant, with six W18V46 engines. The actual values are not directly applicable for any power plant, but will depend on several variables and factors.

Reduced power plant emission levels

Case: Delimara gas conversion

Shanghai Electric Power reduced both electricity production costs and emission levels at their Delimara 3 Power Plant in Malta as eight Wärtsilä HFO-fuelled engines were converted to run on natural gas including installation of the new UNIC C3 engine control system. This means a lower heat rate for the engines, increased efficiency, higher power output capacity, and lower emissions, in other words, reduced operational costs.

News

Wärtsilä gas conversion project will accelerate Senegal’s move to cleaner energy production