Keeping up the thrust

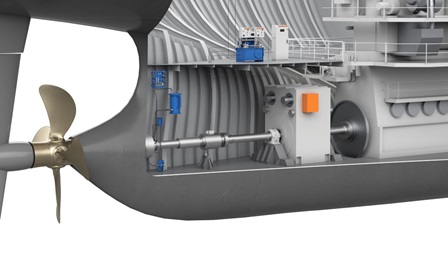

No matter what kind of vessels or platforms you operate, or where they are located, Wärtsilä can provide the parts, repairs, maintenance and modernization solutions to keep propulsion systems running strong and efficiently.

Wärtsilä Propulsion Services offer a complete set of efficiency improving upgrades, as well as environmental solutions, field services, spare parts and technical support. We also offer propulsion controls & monitoring, metallurgical repairs, and underwater services.

Maintenance and spare parts

We supply OEM spare parts and maintenance for Wärtsilä, LIPS and Wichmann propulsion systems as well as seals and bearings systems for all Wärtsilä brands including Cedervall, Japan Marine Technologies (JMT) and Deep Sea Seals (DSS).

Our Field Services team provides outstanding support at yards all over the world. We have our own specialized workshops in various locations, and also offer a full range of underwater repairs to decrease downtime and eliminate the need for dry-docking.

Maximising efficiency and performance

Older propulsion systems have usually been subjected to wear and tear, and spare parts might have become obsolete and scarce. A retrofit or upgrade of e.g. the remote control system and the mechanical parts of the propulsion system can help prevent unexpected maintenance and repair periods that increase operational costs. Propulsion efficiency upgrades or installing energy saving devices brings major savings in fuel costs.

Wärtsilä EnergoFlow

In today’s increasingly competitive shipping environment, you need solutions that not only increase your efficiency, but that are also reliable and have a short payback period. Wärtsilä EnergoFlow is an innovative and cost-effective pre-swirl stator that increases fuel efficiency by up to 10% – without increasing maintenance needs.

Wärtsilä EnergoFlow creates optimal inflow for the propeller by guiding one side of the stern flow in the opposite direction to the propeller rotation, generating pre-swirl. The solution consists of multiple curved fins and a ring attached to the ship’s hull to prevent the power losses that typically occur in a propeller’s slipstream.

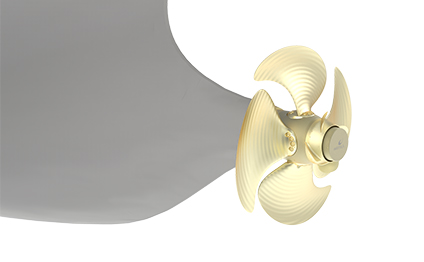

Wärtsilä EnergoProFin

The Wärtsilä EnergoProFin is an energy saving propeller cap with fins that rotate together with the propeller. This solution provides average fuel savings of 2%, with a payback time of less than one year.

The propeller’s energy losses are among the factors related to the flow phenomena around and behind the propeller boss. Installing the Wärtsilä EnergoProFin helps to reduce these energy losses and increase overall propulsion efficiency.

The Wärtsilä EnergoProFin is suitable for all new builds and vessels in operation.

New propeller design

Improving fuel efficiency is considered to be the most effective way to reduce a vessel’s operating costs. Redesigning the propeller can lead to significant efficiency gains for vessels that employ slow steaming to save fuel, but also for fast ferries, which can achieve higher speeds and efficiency gains with modifications to controllable-pitch propeller (CPP) blades.

A new propeller design, along with reduced vessel speeds and engine power, can lead to propulsive efficiency improvements of up to 15%.

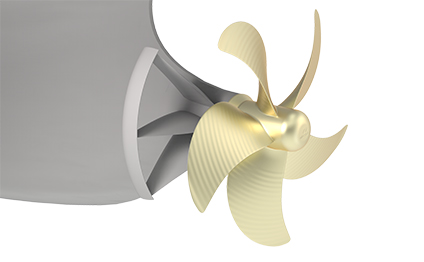

High performance nozzle

Propulsion efficiency is one of the most effective ways of reducing operating costs. The Wärtsilä High Performance (HP) Nozzle improves propulsion efficiency resulting in increased thrust and fuel savings and performs significantly better than the industry standard nozzle types, such as the 19A or 37 type nozzles.

Wärtsilä Underwater services

Performing maintenance and repairs to propellers, thrusters, rudders and stern tube seals while keeping the vessel in service enables uninterrupted operation with the best propulsion efficiency for lower fuel consumption.

Wärtsilä Underwater Services reduce the need for vessel downtime for dry docking and the need for off-hire. By providing OEM quality maintenance, Wärtsilä’s Global Underwater Services save considerable time and money.