Diverse operations require flexible systems to maximise efficiency

Small and medium gas carriers generally transport liquid natural gas (LNG) or liquid petroleum gas (LPG), or other chemical products in gaseous form. Some vessel designs may be tailored for bunkering or ship-to-ship operations. Vessels in this size class need to be adaptable for varying voyage distances, loading conditions, and sailing speeds as well as varying power requirements for cargo handling and port entry and exit operations. Vessel CAPEX and OPEX are crucial to secure profitable and competitive business.

Gas carriers sail under variable cargo loads and with varying operational profiles, meaning propulsive and electrical power requirements can vary greatly. As a result, owners must balance the need to minimise a vessel’s Energy Efficiency Design Index (EEDI) with the need to ensure that installed propulsive power is sufficient to cope with adverse weather conditions as required by the IMO’s MARPOL Convention.

Vessels carrying hazardous or pollutant goods are usually required to have backup steering and navigational systems in case of failure. Small and medium gas carriers also often sail in challenging waters such as channels or fjords, making a reliable propulsion system, effective steering capability and excellent manoeuvrability a must. They may also be sailing in environmentally sensitive areas with strict emission and underwater noise limits. In addition, port operations may take place close to urban areas where even stricter local environmental regulations apply.

Integrated solution for small and medium gas carriers

Hover or click on the symbols to reveal more information on the six parts of the integrated solution.

Small gas carrier DF-DE

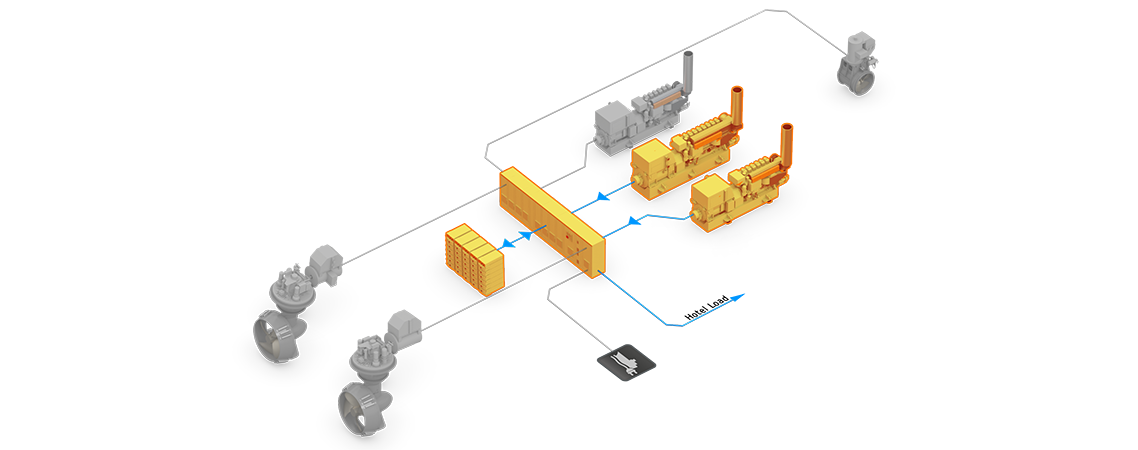

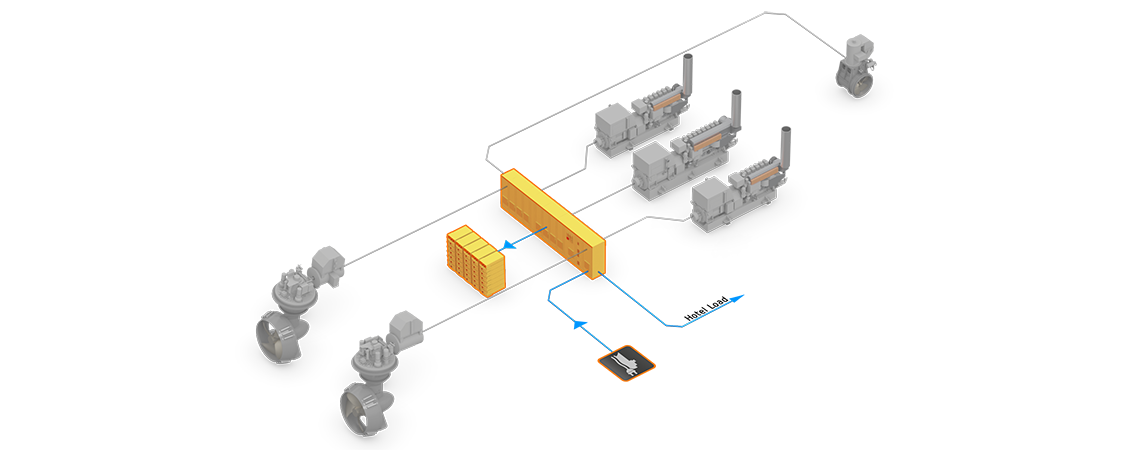

Wärtsilä dual fuel-diesel electric (DF-DE) propulsion system

Emission reduction and operational flexibility are the main drivers behind the development of Wärtsilä propulsion systems for small and medium gas carriers. These highly adaptable, customised propulsion systems can be enhanced with a variety of advanced functionalities according to the intended operational profile of the vessel in question.

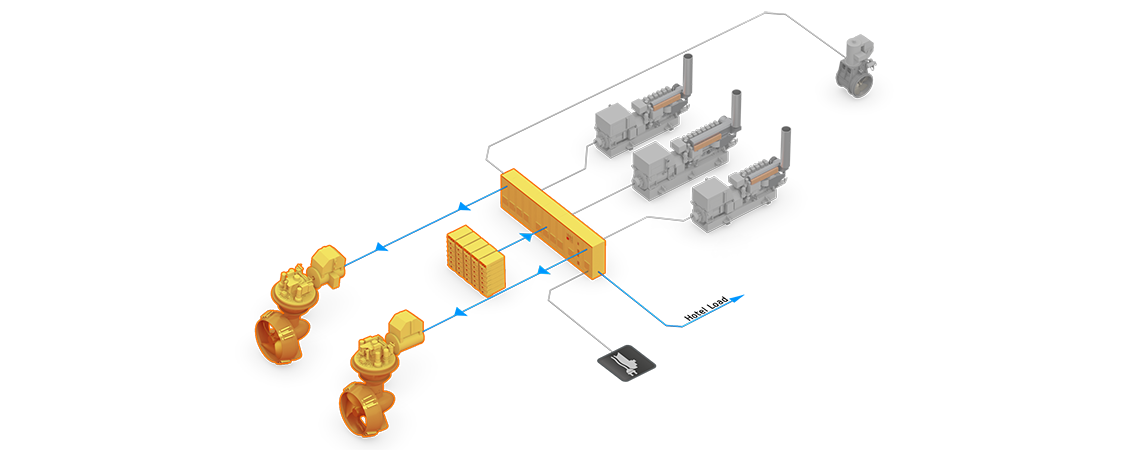

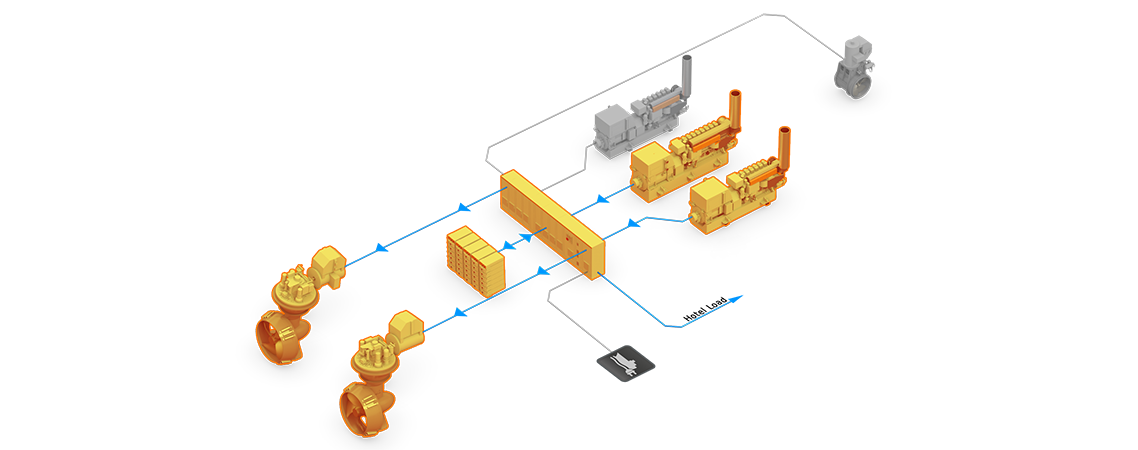

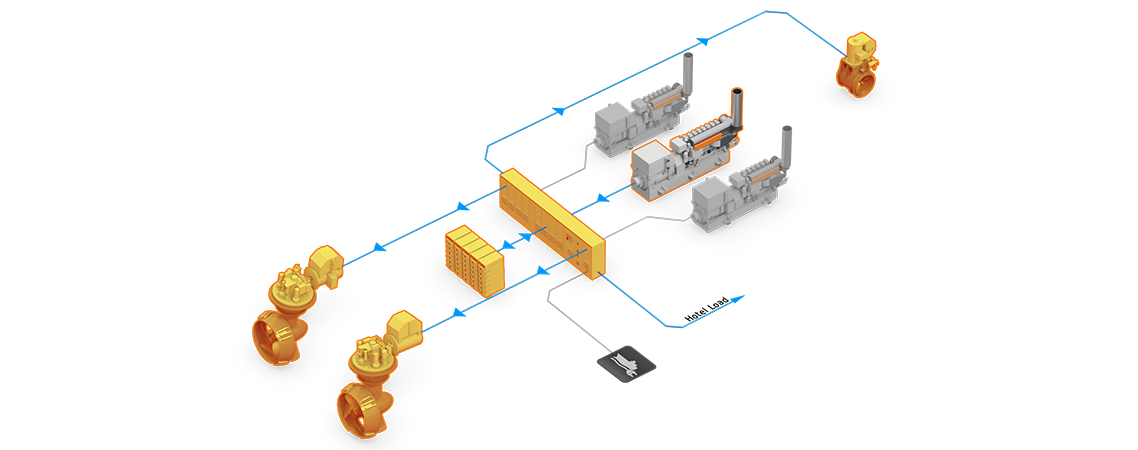

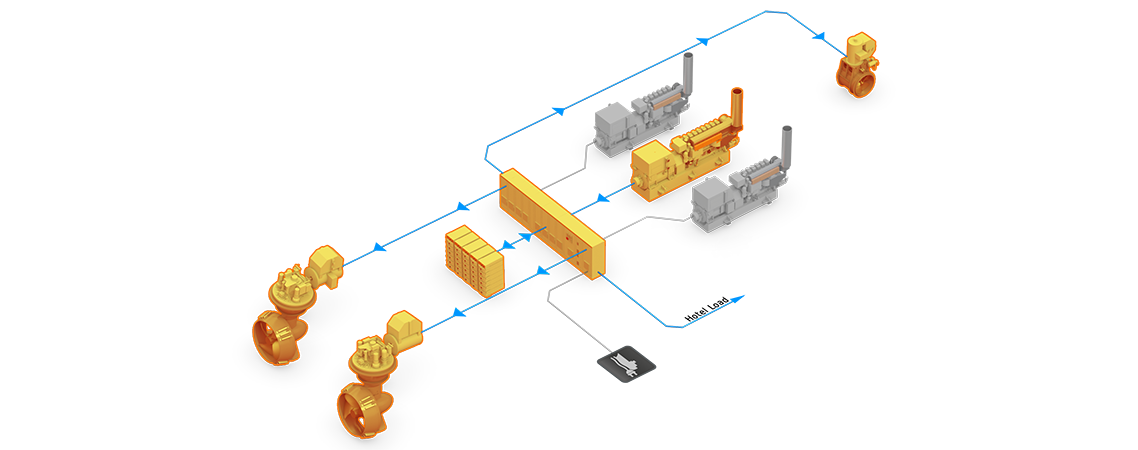

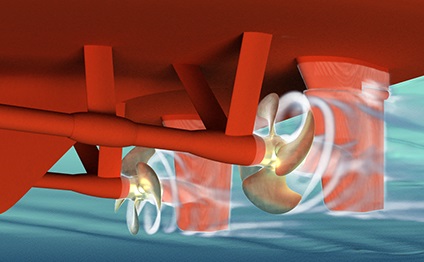

A great option for this vessel type is a diesel-electric hybrid propulsion system that includes fuel-flexible medium-speed gensets, a switchboard and a propulsion motor connected to steerable aft thrusters, a forward tunnel thruster and a battery-based energy storage system (ESS). An integrated Energy Management System (EMS) ensures all the elements work seamlessly together, optimising energy flows to achieve the best performance in all operational modes.

System operational modes for small gas carrier DF-DE

Small gas carrier DF-DE

Expand all

Small gas carrier DF-DM

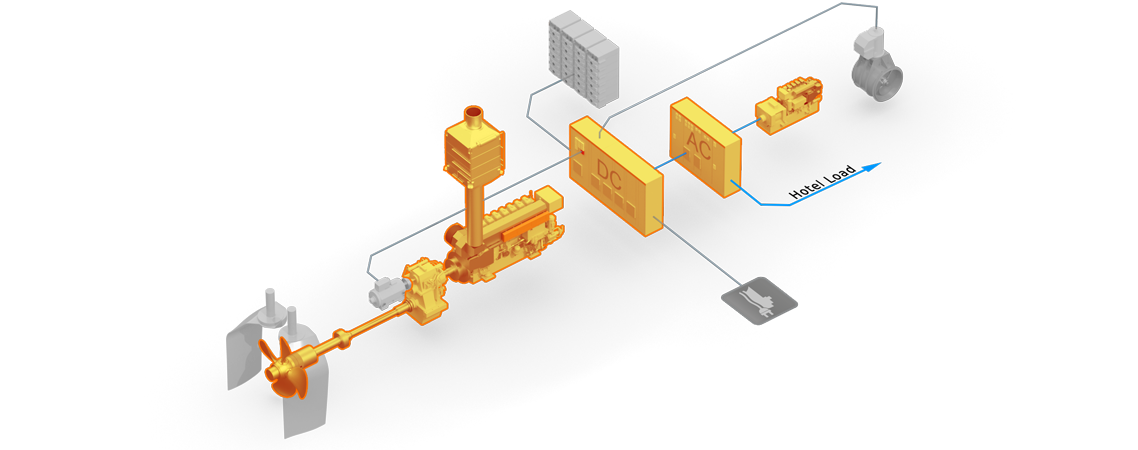

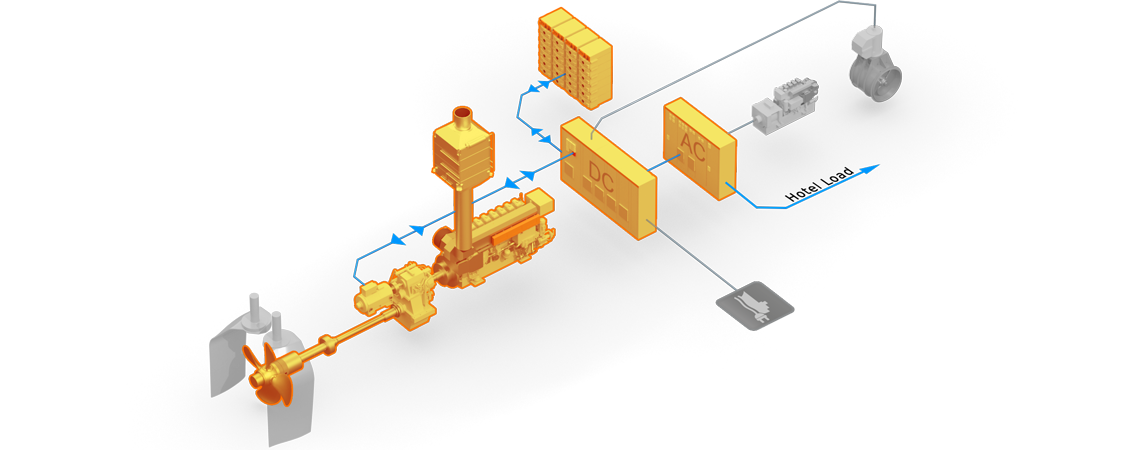

Wärtsilä dual fuel-diesel mechanical (DF-DM) propulsion system

Emission reduction and operational flexibility are the main drivers behind the development of Wärtsilä propulsion systems for small and medium gas carriers. These highly adaptable, customised propulsion systems can be enhanced with a variety of advanced functionalities according to the intended operational profile of the vessel in question.

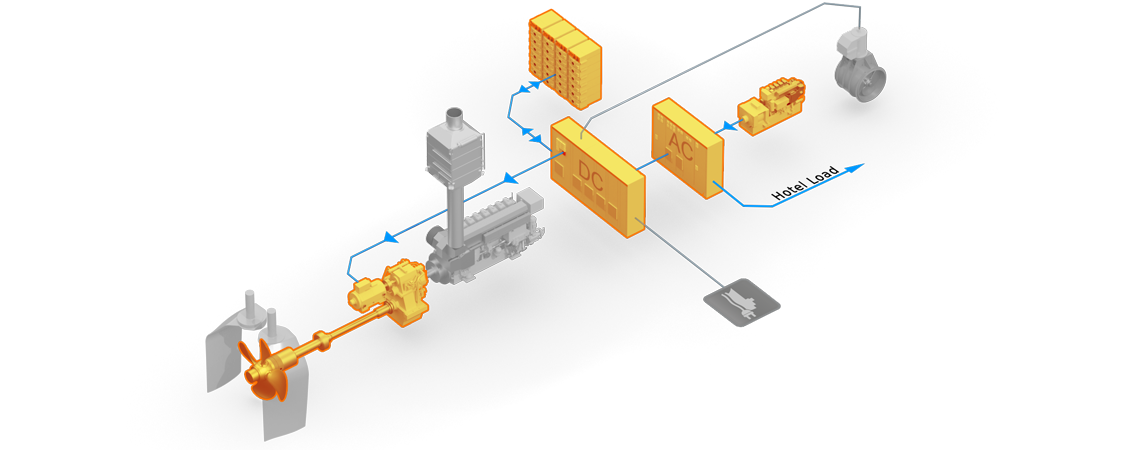

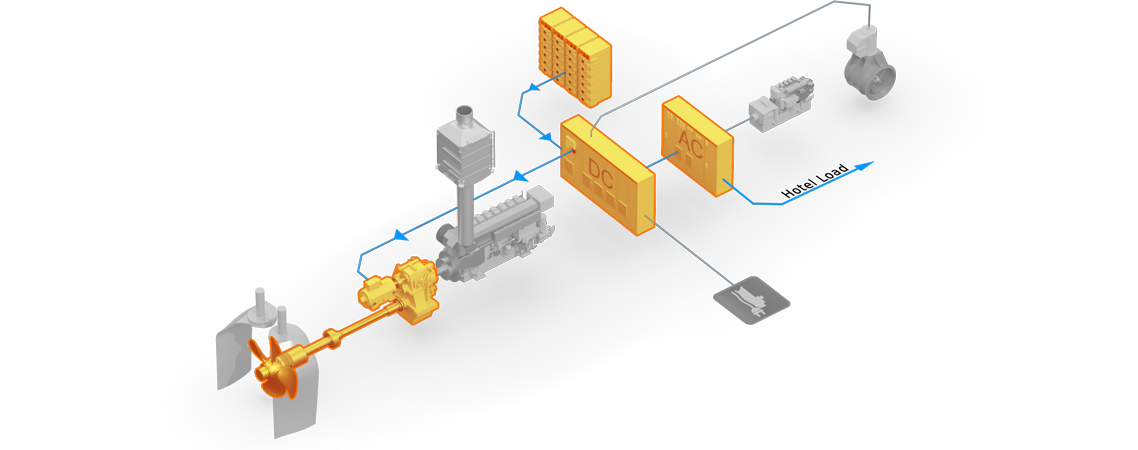

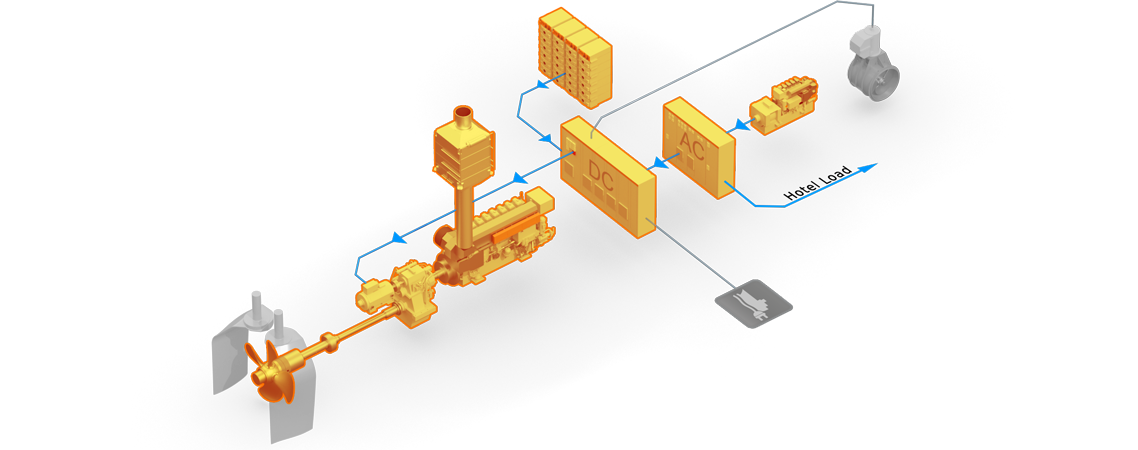

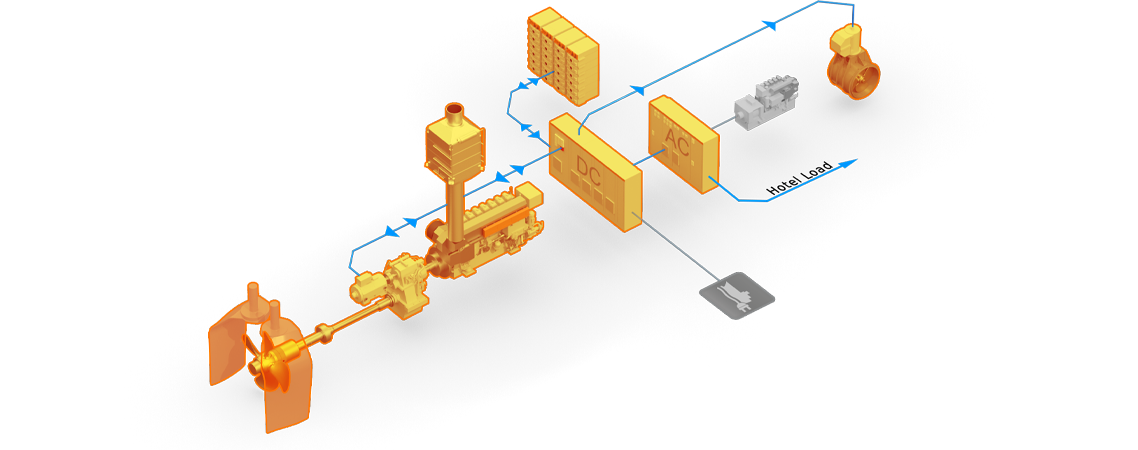

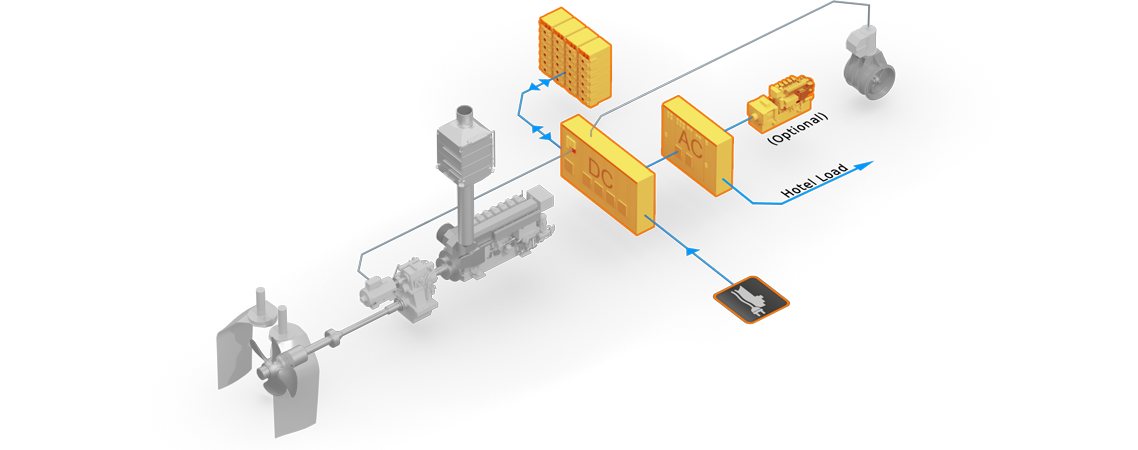

A great option for this vessel type is a hybrid propulsion system that includes a fuel-flexible medium-speed main engine, a geared propeller system, a shaft motor/generator (PTO/PTI) and a battery-based energy storage system (ESS) as well as an auxiliary genset. An integrated Energy Management System (EMS) ensures all the elements work seamlessly together, optimising energy flows to achieve the best performance in all operational modes.

System operational modes for small gas carrier DF-DM

Small gas carrier DF-DM

Expand all

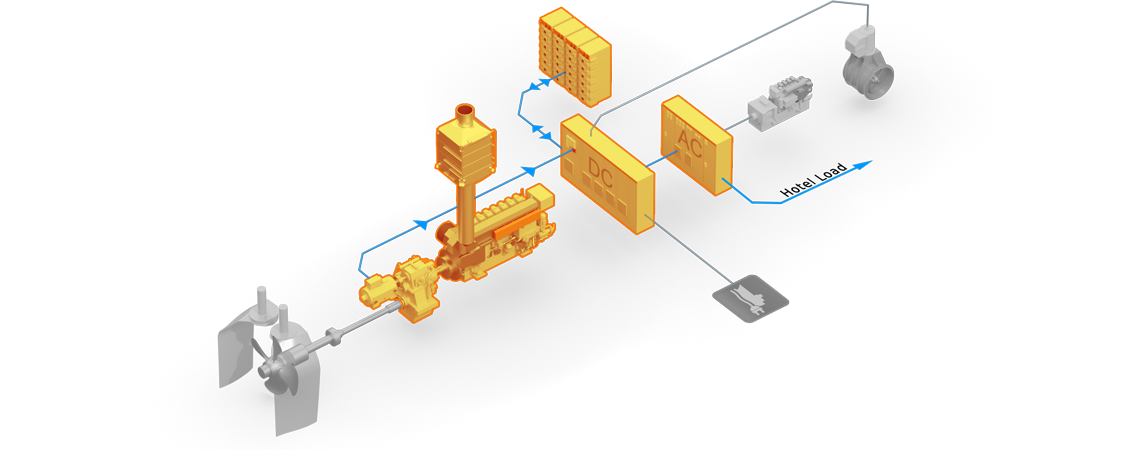

Medium gas carrier

The Wärtsilä propulsion system for this vessel type has a main engine mechanically connected to a CPP through a one-step gearbox with PTO/PTI connection. This helps owners to balance the need to minimise a vessel’s Energy Efficiency Design Index (EEDI) and comply with the IMO’s MARPOL Convention while ensuring that installed propulsive power is sufficient to cope with adverse weather conditions. The Wärtsilä ProTouch Propulsion Control System offers a user-friendly interface and advanced features such as EcoControl. A GATE RUDDER™ can be added for superior efficiency and manoeuvrability and a bow thruster to further enhance manoeuvrability.

System operational modes for medium gas carrier

Medium gas carrier

Expand all

Essential solutions for small and medium gas carriers

Hand-picked press releases

Renewal of Wärtsilä Maintenance Agreement emphasises continuation of a successful collaboration

The technology group Wärtsilä has signed a five-year renewal of its existing Maintenance Agreement with Norway’s Höegh LNG Fleet Management (HLNG). The renewed agreement includes delivery of spare parts and field maintenance services, as well as Wärtsilä’s latest digital solutions and extends the value-adding cooperation between the two companies. The order was included in Wärtsilä’s order book in December 2022.

The agreement covers maintenance on the Wärtsilä 50DF dual-fuel engines installed on ten vessels, nine of which are operating as Floating Storage and Regasification Units (FSRUs). One of these FSRUs, the ‘Höegh Esperanza’, is currently being used to supply gas to the new LNG terminal in Wilhelmshaven, Germany.

The scope of the agreement includes digital solutions such as Wärtsilä’s unique Expert Insight predictive maintenance service, Remote Operational Support, Data-driven Dynamic Maintenance Planning, and fluids management service. Also included is the use of a new collaboration app. The app makes communication between HLNG’s technical crew and Wärtsilä experts easy and manages all necessary reporting. HLNG has direct access to the Wärtsilä Expertise Centres providing support and guidance round-the-clock.

“We recognise Wärtsilä as a technology leader in developing efficiency-based solutions that support decarbonisation efforts, which is an important target for our company. We see this renewed agreement as providing a solid foundation for continued cooperation, and a partnership for joint projects towards decarbonised operations,” says Nils Jakob Hasle, SVP, Head of Fleet Management at Höegh LNG.

“Renewal of the earlier agreement is an endorsement of its value to our customer. It also positions Wärtsilä to continue to support Höegh LNG on their decarbonisation and digital development journey. Expert Insight and the remote support services offered enables issues to be resolved proactively without having to have the physical presence of a service engineer. These services also lessen the environmental footprint and address concerns regarding cyber security,” says Henrik Wilhelms, Director Agreement Sales at Wärtsilä.

HLNG is a long-time customer of Wärtsilä, and the two companies have collaborated on various projects aimed at improving efficiencies and reducing emissions.

Media contact for more information on this release:

Nicole Lyons

Global Communications Manager

Wärtsilä Marine Power

Tel: +44 (0) 78241 38855

marine.media@wartsila.com

Image caption: STS operation with the FSRU Independence © Höegh Lng As

All Wärtsilä releases are available at https://www.wartsila.com/media/news-releases and at http://news.cision.com/wartsila-corporation where also the images can be downloaded.

Wärtsilä in brief:

Wärtsilä is a global leader in innovative technologies and lifecycle solutions for the marine and energy markets. We emphasise innovation in sustainable technology and services to help our customers continuously improve their environmental and economic performance. Our dedicated and passionate team of 17,500 professionals in more than 240 locations in 79 countries shape the decarbonisation transformation of our industries across the globe. In 2022, Wärtsilä’s net sales totalled EUR 5.8 billion. Wärtsilä is listed on Nasdaq Helsinki.

www.wartsila.com