Integrated solutions for small and medium gas carriers

Wärtsilä delivers integrated hybrid solutions for small and medium gas carriers, helping owners achieve efficiency, compliance, and long-term flexibility. Our offering covers LNG, LPG, and multi-gas vessels, with a special focus on LNG bunkering vessels, a fast-growing segment in global shipping.

Whether you operate a regional LNG carrier, LNG bunkering vessel, or a multi-purpose gas transporter, Wärtsilä helps you cut operating costs, reduce emissions, and prepare for future fuels. Our modular approach combines the following into one optimised system:

- propulsion

- power

- energy storage

One optimised system will help your vessel stay competitive for decades.

With Wärtsilä, you gain proven technology, lifecycle support, and the confidence that your ship meets today’s environmental rules and tomorrow’s challenges.

Why owners choose Wärtsilä

- Lower costs and fewer emissions. Hybrid-electric systems optimise power use and cut fuel consumption. Energy storage reduces genset running hours and smooths load changes. All these help you meet IMO efficiency targets and operate more sustainably.

- Adaptable for changing conditions. Small and medium gas carriers face different voyage lengths, cargo loads, and port requirements. Wärtsilä solutions adjust to these variations. You will avoid installing excess power while still having enough propulsion for safety in rough seas.

- Safe operations in demanding waters. Gas carriers often handle hazardous cargo and sail through narrow channels or fjords. Wärtsilä provides reliable propulsion, advanced steering, and backup systems to keep your vessel safe and manoeuvrable.

- Ready for future compliance. Environmental rules are tightening in ports and sensitive areas. Wärtsilä’s modular design makes it easier to upgrade to future fuels like ammonia and methanol. Your investment can stay competitive for decades.

Proven solutions for small and medium gas carriers

Explore Wärtsilä’s most trusted solutions for small and medium gas carriers. Each combines innovative technology with real-world performance to help you cut costs, reduce emissions, and stay future-ready.

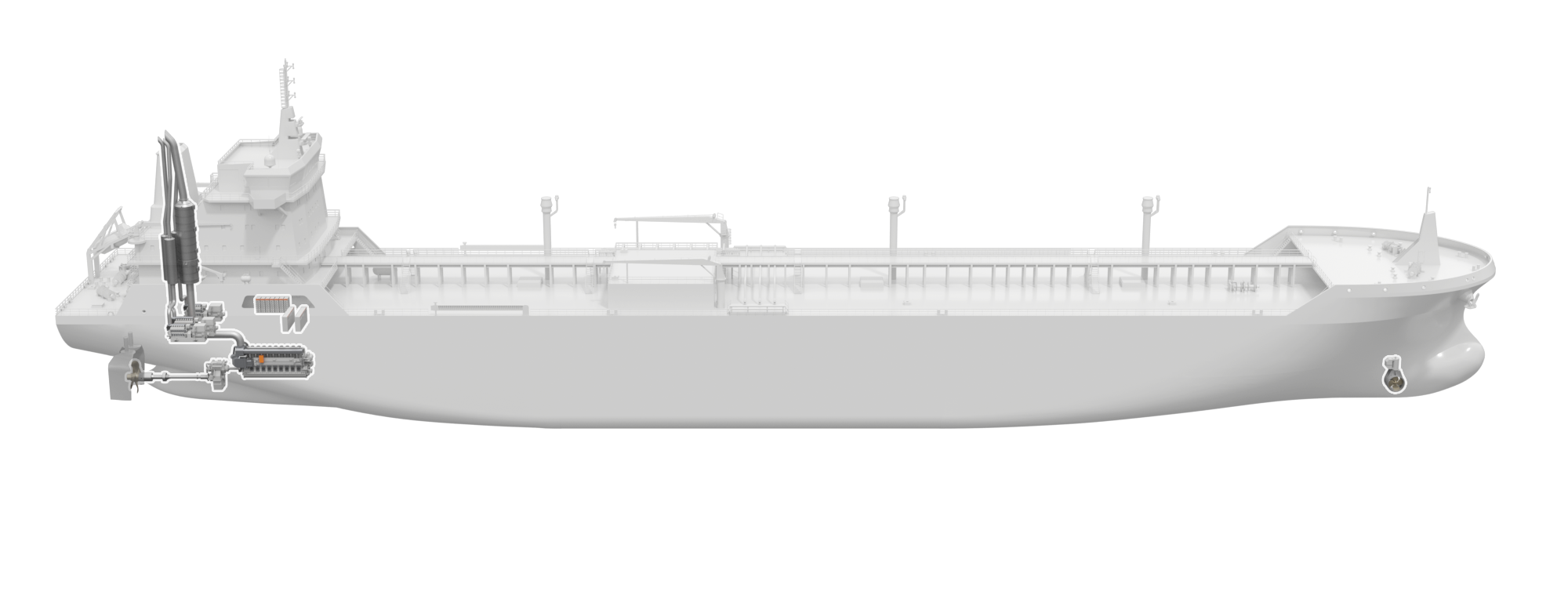

Integrated solution – scope of supply

To meet IMO and regional decarbonisation targets, Wärtsilä offers a fully integrated solution for small and medium gas carriers. It optimises efficiency and minimises emissions across all operating profiles.

Decarbonisation

Wärtsilä’s hybrid system HY improves overall efficiency and reliability while reducing installed mechanical power. This helps you achieve a lower EEDI and stay compliant with current and future CII targets. Flexible propulsion means longer lifetime and lower emissions even under variable conditions.

Propulsion

The main engine connects to a controllable pitch propeller CPP via a gearbox with PTO/PTI options. This set-up can adapt to energy efficiency rules and requires minimum power in harsh weather. Wärtsilä ProTouch™ makes control simple, while Gate Rudders and bow thrusters boost manoeuvrability and fuel economy.

Main engine

Wärtsilä’s 4-stroke medium-speed engine offers unmatched fuel flexibility—it can consume boil-off gas (BOG) directly. Our portfolio includes engines that are ready for future fuels such as ammonia or methanol. Advanced mountings reduce vibration and underwater noise, and exhaust aftertreatment options help you meet emissions regulations.

Power conversion

Power is managed through an AC system with a DC Hub. A variable-speed shaft generator provides efficient power during sailing and can drive the bow thruster without affecting propulsion. Shore connection in port and auxiliary gensets ensure backup power when needed.

Fuel storage and supply

Our solutions can adapt to multiple fuels, from conventional liquids and LNG to future fuels such as ammonia or methanol. Compact 4-stroke engines save space compared to 2-stroke designs, which gives you flexibility for future fuel storage requirements.

Battery-based ESS

The Energy Storage System ESS connects to the DC Hub to enable hybrid functionality for propulsion and cargo handling. It supports spinning reserve, reduces genset running hours, and can be sized to your vessel’s operating profile. Thanks to the DC Hub, adding solar panels or fuel cells later is simple.

Special focus: LNG bunkering vessels (LBVs)

Why LBVs matter

LNG bunkering vessels are essential for supplying cleaner fuel to ships. They spend much of their time in harbour or during ship-to-ship transfers, where efficiency and low emissions are critical. Wärtsilä’s integrated package combines hybrid-electric propulsion with advanced cargo handling and boil-off gas management to make these operations safe, sustainable, and cost-effective.

Hybrid electric LNG bunkering vessel solutions

Our approach reduces fuel use, cuts methane slip, and ensures compliance with strict port regulations. It also gives you flexibility for future fuels, so your investment remains competitive for decades.

Key facts: What makes Wärtsilä LBV solutions stand out

Integrated systems

Complete power system including engines, catalyst systems, propulsion, fuel supply system and energy saving devices.

Hybrid-electric propulsion

Dual-fuel engines with Energy Storage and Management for zero-emission port windows and smoother power profiles.

Future fuels

Modular design supports ammonia, methanol, and easy integration of fuel cells or solar power.

How Wärtsilä solutions perform in operation

Gas carriers operate under very different conditions, from harbour manoeuvring to long-distance sailing. Because Wärtsilä’s integrated solutions are designed to optimise efficiency and reliability across operational modes, your vessel will perform economically and safely.

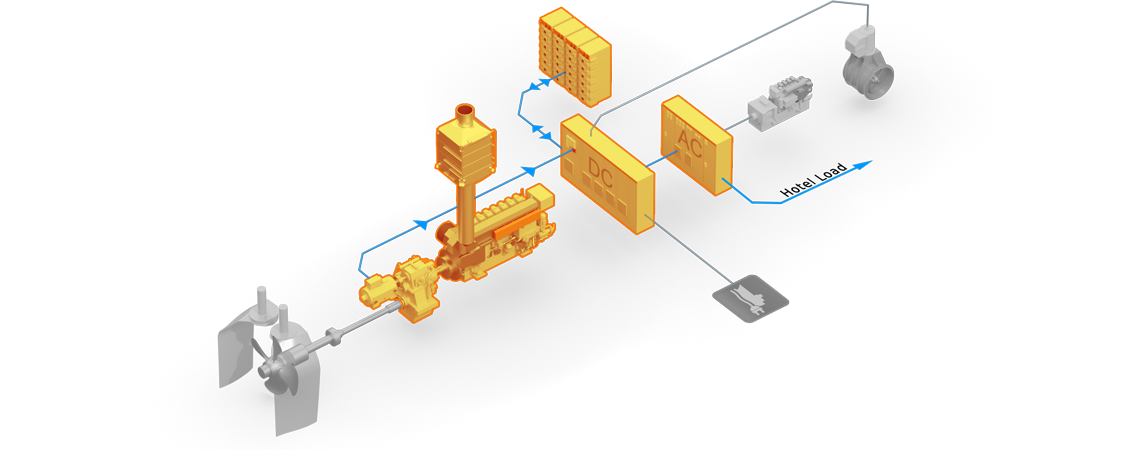

Small gas carrier DF-DE

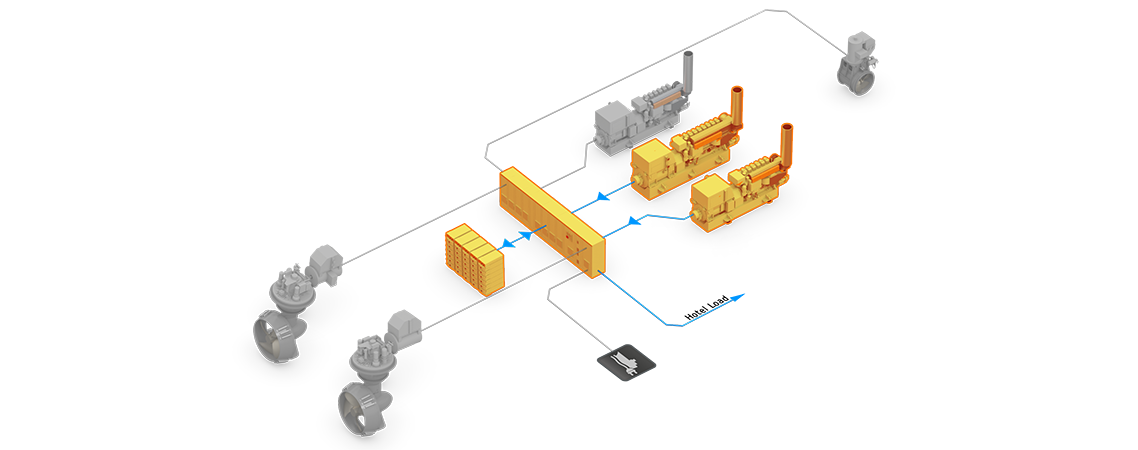

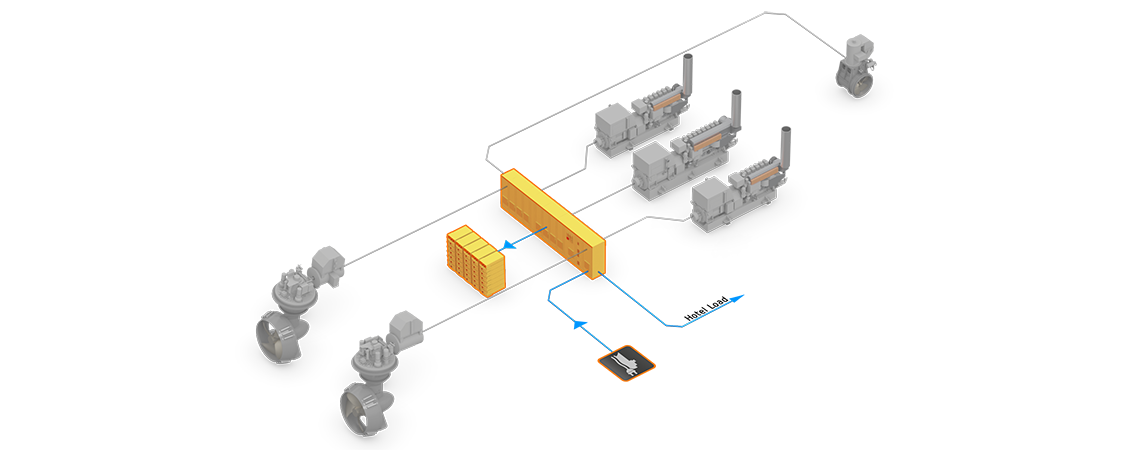

Small gas carrier – Diesel Electric (DF-DE)

This setup uses multiple dual-fuel gensets to power propulsion and onboard systems. It offers flexibility for vessels that spend more time in port or short voyages. Wärtsilä’s hybrid option adds batteries and energy management to reduce fuel use, cut emissions, and provide zero-emission windows during harbour operations.

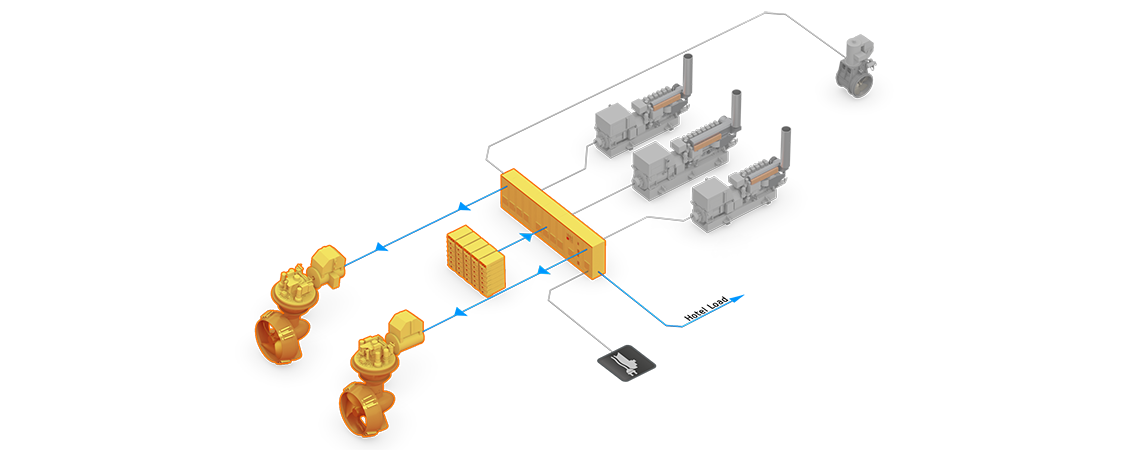

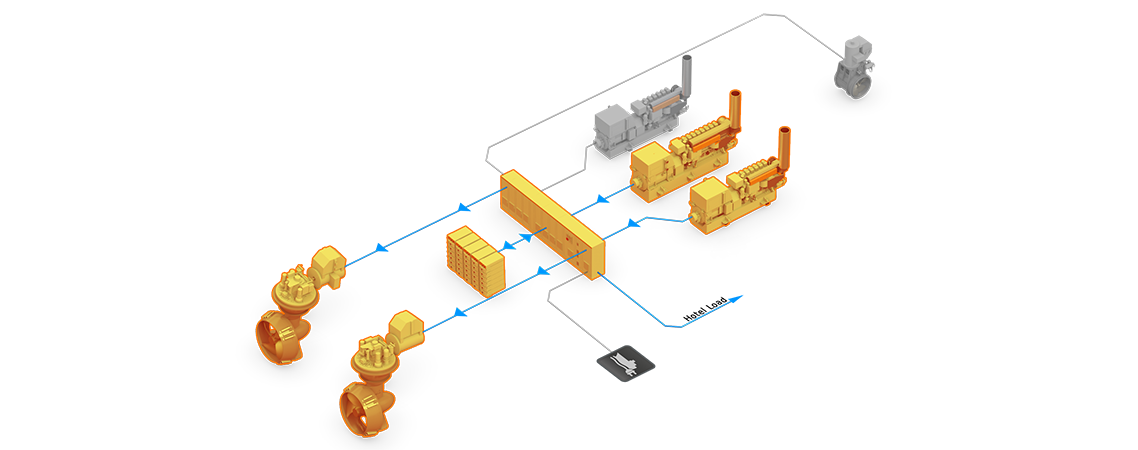

System operational modes for small gas carrier DF-DE

Small gas carrier DF-DE

Expand all

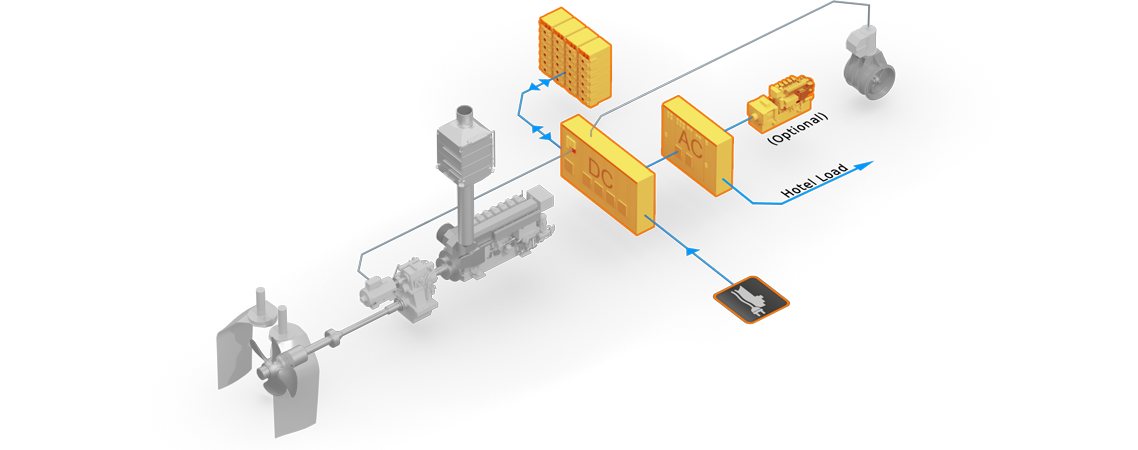

Small gas carrier DF-DM

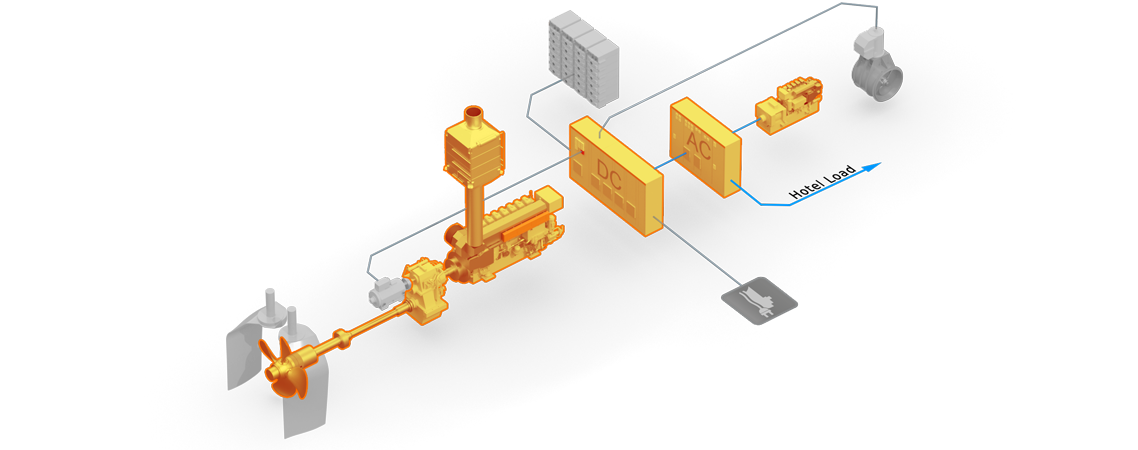

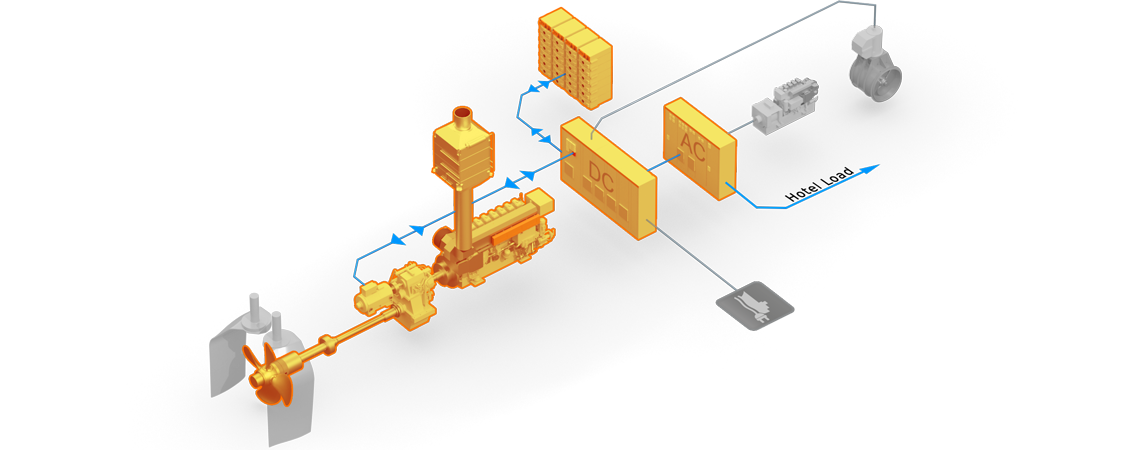

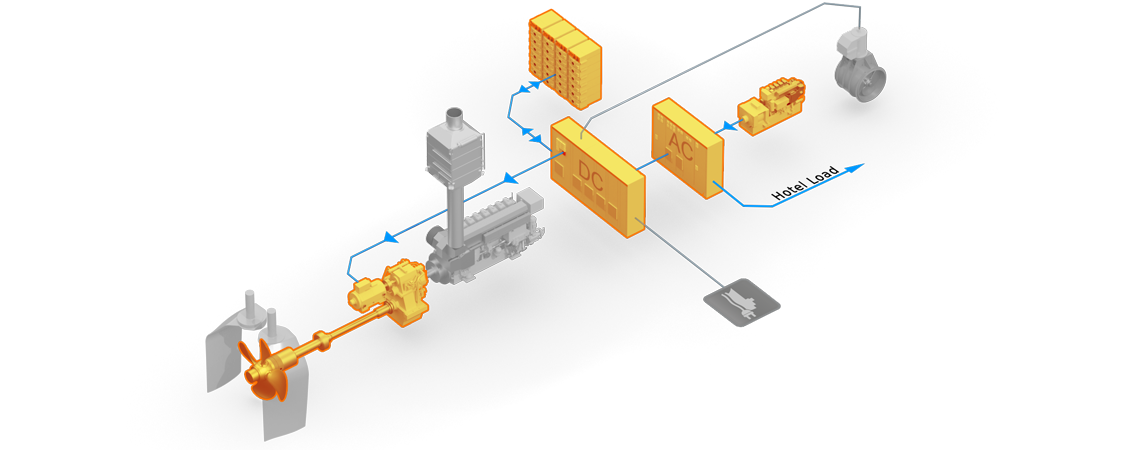

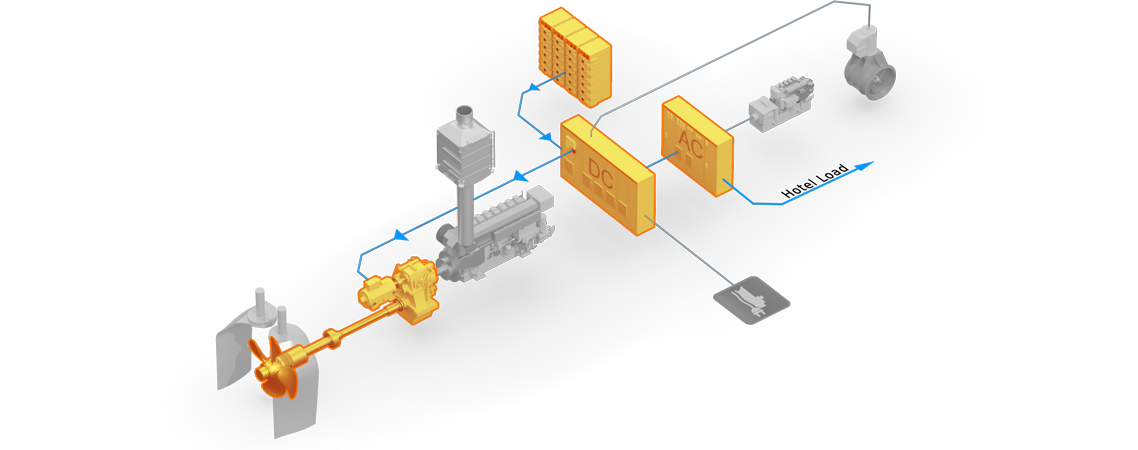

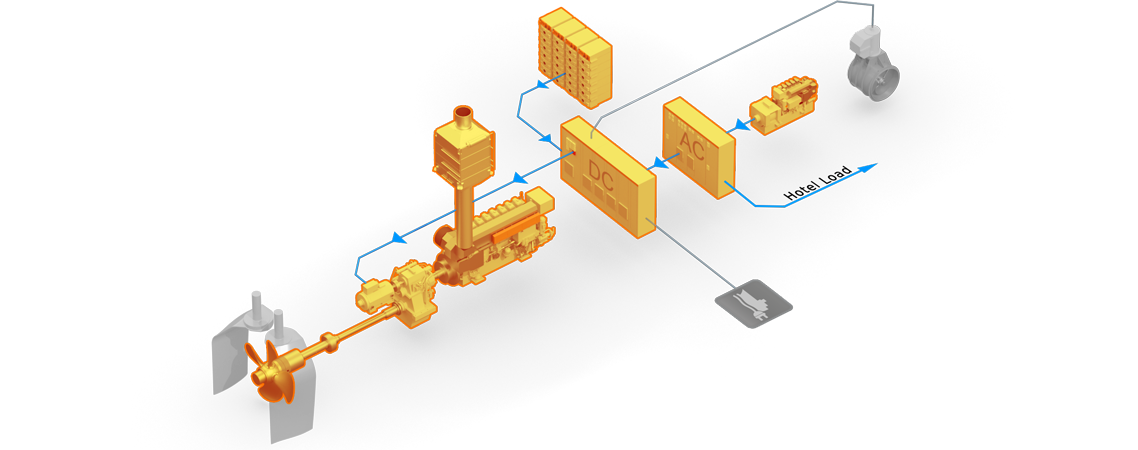

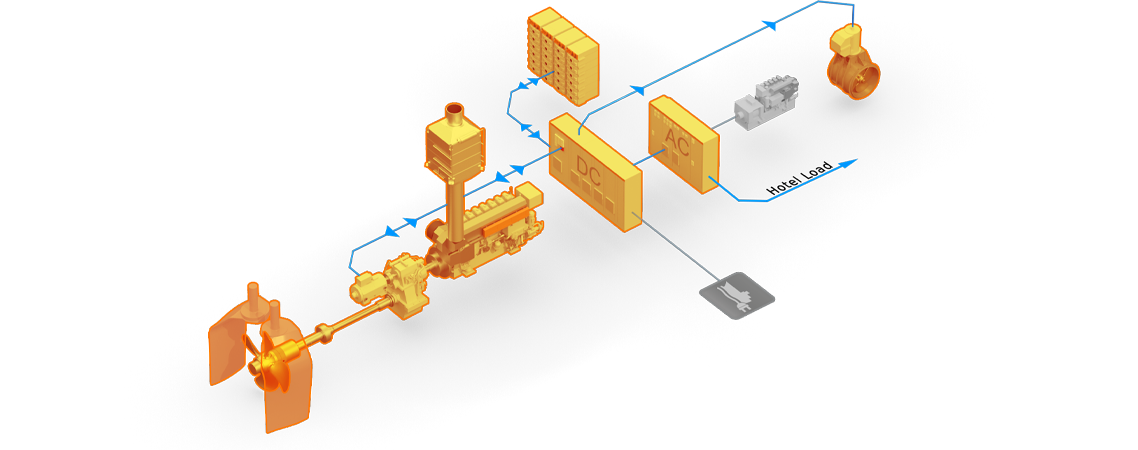

Small gas carrier – Diesel Mechanical (DF-DM)

Here, a main engine drives the propeller directly, supported by auxiliary gensets for hotel loads and cargo pumps. Wärtsilä’s solution improves efficiency with PTO/PTI options and hybrid integration, so you can recover energy and reduce running hours. This means lower operating costs and compliance with tightening efficiency rules.

System operational modes for small gas carrier DF-DM

Small gas carrier DF-DM

Expand all

Medium gas carrier

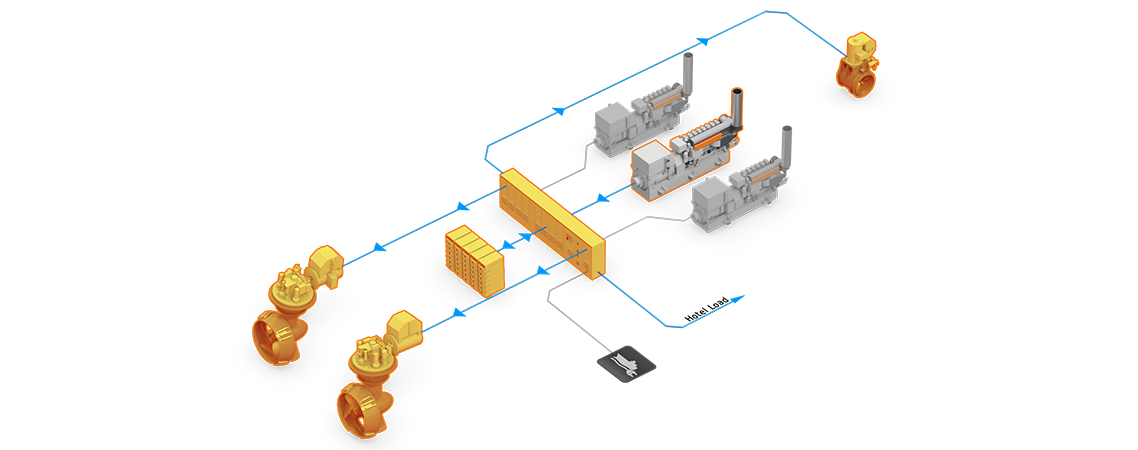

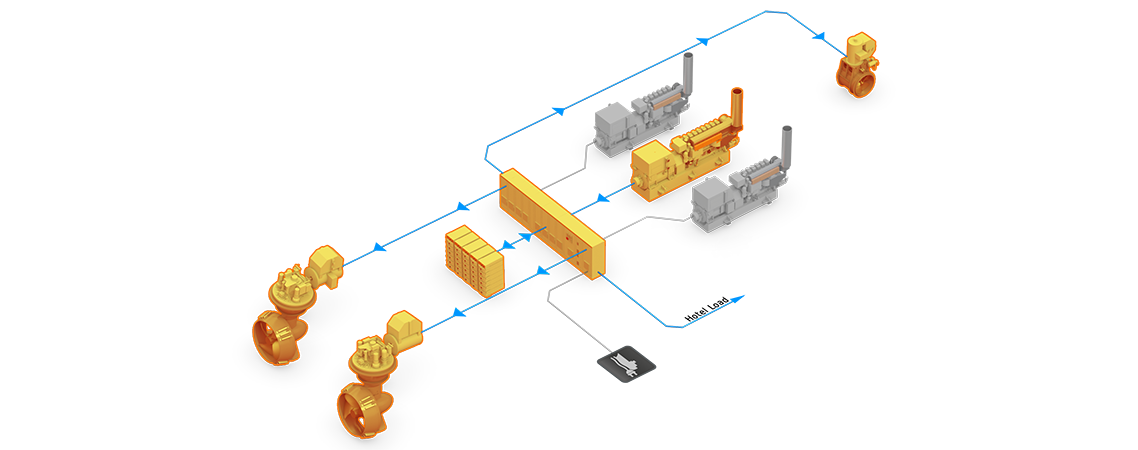

Medium gas carrier – Flexible hybrid concept

Medium carriers often sail longer routes and face variable cargo loads. Wärtsilä combines dual-fuel engines with hybrid-electric technology to keep power stable and emissions low. Energy storage supports peak shaving and spinning reserve, while modular design makes future fuel upgrades simple.

System operational modes for medium gas carrier

Medium gas carrier

Expand all

Proven solutions

Wärtsilä’s innovative technology can ensure that gas carriers are efficient and future-ready. An excellent example is the Spanish operator Grupo Ibaizabal, a decarbonisation pioneer in the LNG bunkering vessel segment.

How Ibaizabal’s LNG bunkering vessel cuts methane slip

Wärtsilä 25DF engines with NextDF technology achieve dramatic reduction in methane slip, lowering the risk of FuelEU Maritime penalties.

Frequently asked questions

Hand-picked press releases

Ready to power your next gas carrier?

Discover how Wärtsilä’s integrated solutions can make your vessel efficient, compliant, and future-ready. Let’s turn your plans into proven performance.

This page was written with the help of AI. A human expert has checked and verified the contents.