Top technologies for cruise ships and engines

Whether you're upgrading an existing vessel or planning a newbuild, Wärtsilä can help you cut fuel costs, meet regulations, and elevate the passenger experience – all while protecting your bottom line. From quiet, efficient propulsion systems to digital twins that guide smart decarbonisation investments, we give you the tools to make confident, data-driven decisions.

Turn insight into impact: with Wärtsilä, you’re not just meeting today’s regulations—you can be shaping a more profitable, sustainable future for your fleet.

Most popular next steps

Decarbonisation and cruise lines

The ambition in the cruise industry is to go above and beyond – to exceed expectations. This is as true for the guest experience as it is for the industry’s drive to reduce emissions and decarbonise.

The strive to decarbonise operations is the key challenge for the maritime industry in general, and for the cruise businesses in particular.

Three ways cruise lines can decarbonise

Wärtsilä promotes a three-level approach to the maritime decarbonisation journey:

- Make operations more efficient. Use energy-saving technologies, upgrade engines, and optimise systems.

- Adopt alternative energy sources. Choose engines compatible with LNG, bio-LNG, methanol, and adopt hybrid solutions and shore power.

- Clean up emissions. Install scrubbers, WESPs, SCR systems, and explore carbon capture solutions.

Here’s a more detailed list of actions that cruise lines can take to drive decarbonisation.

Making operations more efficient

Existing cruise ships can benefit from a variety of solutions that help improve the efficiency of operations. For example:

- Energy-saving technologies (ESTs)

- Upgrades and repowering for 4-stroke engines

- Solutions for 2-stroke engines

- Converter and switchboard upgrades

- Shaft generator upgrades

- Hybrid solutions and upgrades

- Optimisation solutions and services

Adopting and using alternative energy sources

New cruise ships must prepare for the future and choose engine technology which runs or has the capability to run on alternative fuels.

- Engine technology, capable to run on alternative fuels such as

- LNG and bio-LNG, which are increasingly popular choices for cruise ship owners

- Methanol - Hybrid solutions

- Shore power solutions and upgrades

Cleaning up emissions

If a ship cannot run on alternative fuels, the smart choice is to clean up emissions.

- Exhaust Gas Cleaning (EGC) or scrubbers acting on SOx

- Wet Electro-Static Precipitators (WESPs) acting on particulate emissions

- Exhaust Gas Recycling (EGR) or Selective Catalytic Reduction (SCR) acting on Nox

- Carbon Capture and Storage (CCS) solutions acting on CO2

All three levels of action are necessary, and for all three, Wärtsilä can offer effective solutions: engines, propulsion solutions, abatement solutions, innovative maritime technology, and services. Integrated solutions from Wärtsilä can give you just what you need to stay competitive, compliant and profitable.

Over the lifetime of a cruise ship, new technologies and fuels will become available. It is essential to have the future in mind to meet regulations, passenger demands and financiers’ preferences.

Discover the opportunities of hybrid systems

Watch now! In less than a minute, Maikel Arts, GM Technical Sales at Wärtsilä will reveal some interesting opportunities that hybrid systems can offer to the cruise industry.

How to be compliant with regulations

Staying up-to-date and compliant with international maritime regulations is essential for your cruise fleet, and Wärtsilä's solutions make it so much easier. For example, our digital tools offer real-time monitoring and reporting, so you can easily track and prove compliance with emissions and safety standards.

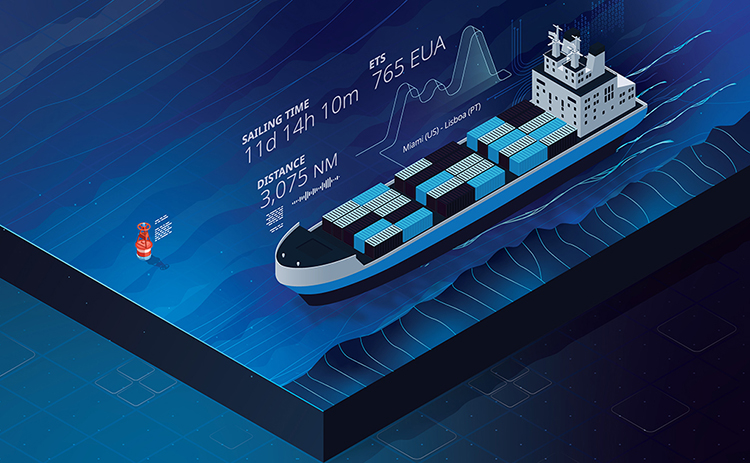

A handy tool that helps you plan, measure and report EUA costs. Accurately and easily!

How to be smarter about services

Decarbonisation discussions often concentrate on fuel-saving, but one should not overlook the effect of maintenance. A well-maintained cruise ship with a clean hull will save fuel and generate less emissions. Simple maintenance practices can have a surprisingly big impact on the efficiency of your ship.

And though some improvements may be small, make enough of them and they will add up to substantial fuel savings – and therefore a significant reduction in emissions.

Learn more about the effect of maintenance practices on your decarbonisation success: “One simple secret that will make your emissions reduction strategy look awesome”.

Did you know that the guaranteed asset performance service helped Carnival decarbonise? Learn more from this case study on a win-win partnership between Carnival and Wärtsilä.

A service agreement can keep you a step ahead

Managing the lifecycle of your vessels and other assets is the key to your competitiveness. And you won’t have to do that alone. Wärtsilä can help you in so many ways.

If you are planning a new cruise ship, you may think that as long as you have a warranty, you’re well covered. But there are six eye-opening reasons you should think again.

Decarbonisation services offer data-led advice

Decarbonisation services can help you to find your optimal decarbonisation path. You will get help for selecting the right solutions and technologies which will make the most economic sense.

When you are looking for the right decarbonisation strategy for your cruise ship, three simple steps with an expert will help you avoid investment risks:

- Analysis of the current fleet

- Modelling and data analysis

- Selecting the right solutions

How Princess Cruises found the best ways to decarbonise

Watch this video to learn how Princess Cruises discovered the best way to decarbonise their fleet with the help of Wärtsilä Decarbonisation Services.

What could your financial benefits be?

Imagine reducing your operational costs while improving your fleet's efficiency. With Wärtsilä, you benefit from the lowest total cost of ownership—because while engines matter, fuel is your biggest expense. Our solutions are designed to help you:

- Save significantly on fuel with our high-efficiency engines and hybrid propulsion systems. These technologies use less fuel, which means lower expenses for you.

- Benefit from energy-saving technologies which help ensure that every bit of fuel is used effectively, saving you even more over time.

- Cut maintenance costs thanks to our durable, reliable equipment that keeps your vessels running smoothly with fewer breakdowns and less downtime.

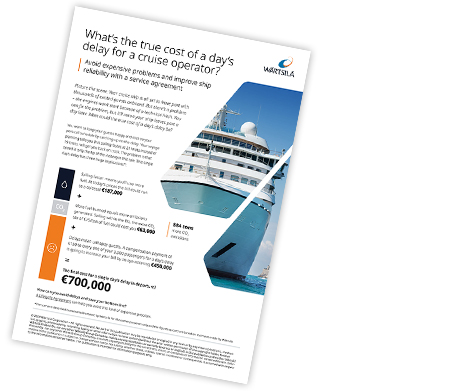

How to avoid the really expensive problem

Picture the scene: Your cruise ship is set to leave port with thousands of guest onboard. But there’s a problem which means your ship leaves port a day later than it should. What is the true cost of a day’s delay for a cruise operator? And how could you avoid such expensive problems?

Customer stories from the cruise industry

Discover the benefits others have already gained from choosing Wärtsilä.

Essential webinars

What everyone in the cruise industry should know about future-proof maritime solutions. Register now! Or catch up on webinar recordings.

Important insights

Discover these hand-picked articles to learn about the many solutions for future-proof, sustainable cruise ship operations.

Latest news for the cruise industry

Frequently asked questions

Wärtsilä’s cruise ship solutions, from hybrid propulsion to LNG systems can be part of your path to decarbonisation. Choose Wärtsilä, and you're not just getting great technology; you're making a smart financial decision for your cruise operations.

Let’s talk about your fleet’s future. Contact us to start your journey.