Vessel battery charging

Vessel charger solutions are designed for ships that have an energy storage system including a marine battery. A marine charging system works in much the same way as a charging system for electric road vehicles. Unlike alternative marine power (AMP) systems, vessel charging systems are not yet standardised and often require fast charging or DC charging, although normal charging or AC vessel charging is also possible.

There are two types of charging systems:

Manual marine charging systems

With a manual vessel charger the operator manually connects their vessel to the shore power charging station. This type of vessel charging is typically used for vessels that do not have short turnaround times. Wärtsilä is delivering a manual marine vessel charging solution for a fast, zero-emission passenger ferry as part of the TrAM Project. This will be the first marine charging system to use the CCS plug standard that is common in the automotive industry.

Automated marine charging systems

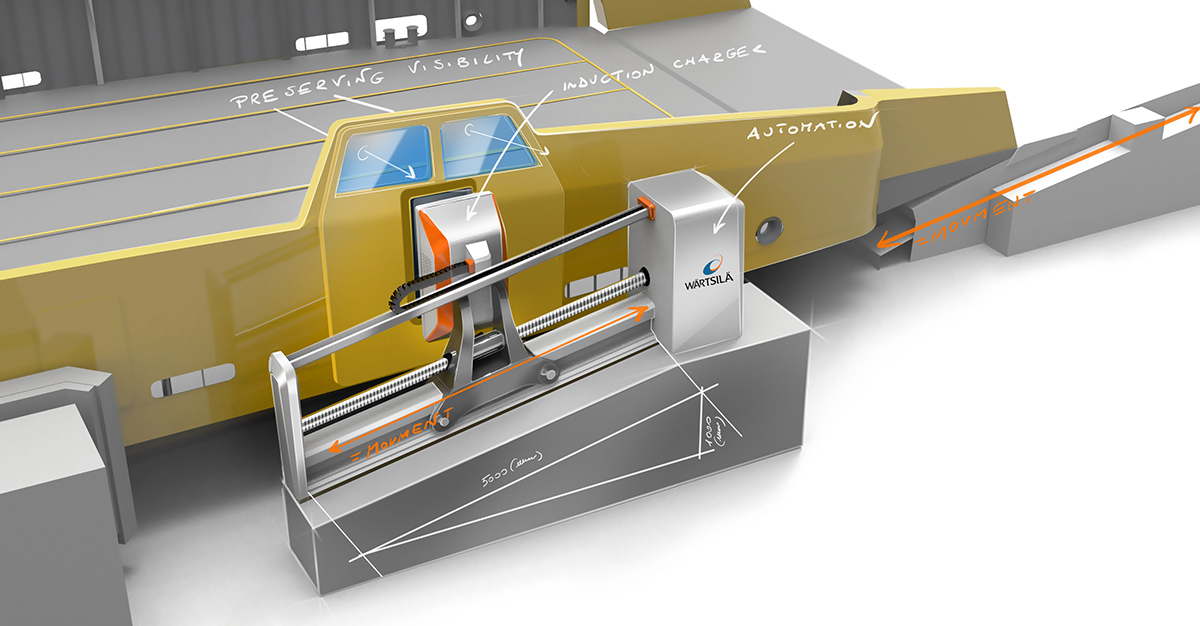

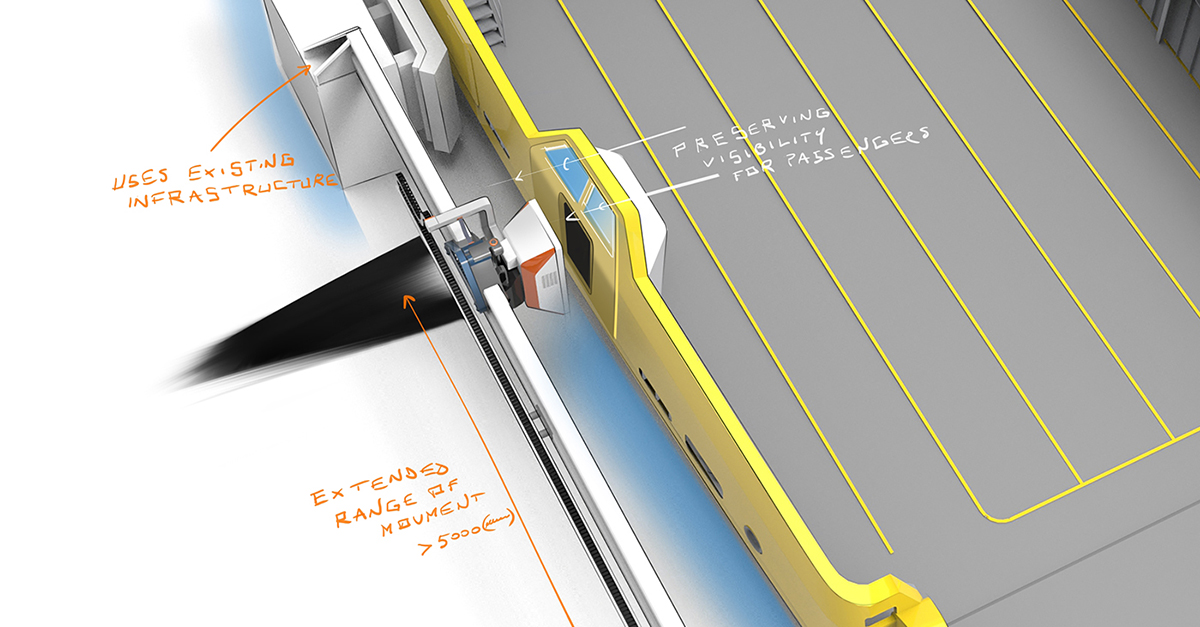

Automated vessel charging maximises the time available for charging an electric or hybrid vessel by starting the vessel charging process as soon as the ship is in range of the wireless charger. Wärtsilä has delivered wireless marine charging systems including charging towers for two zero-emission ferries operate by the Norwegian company Boreal Sjö.

Wireless charging

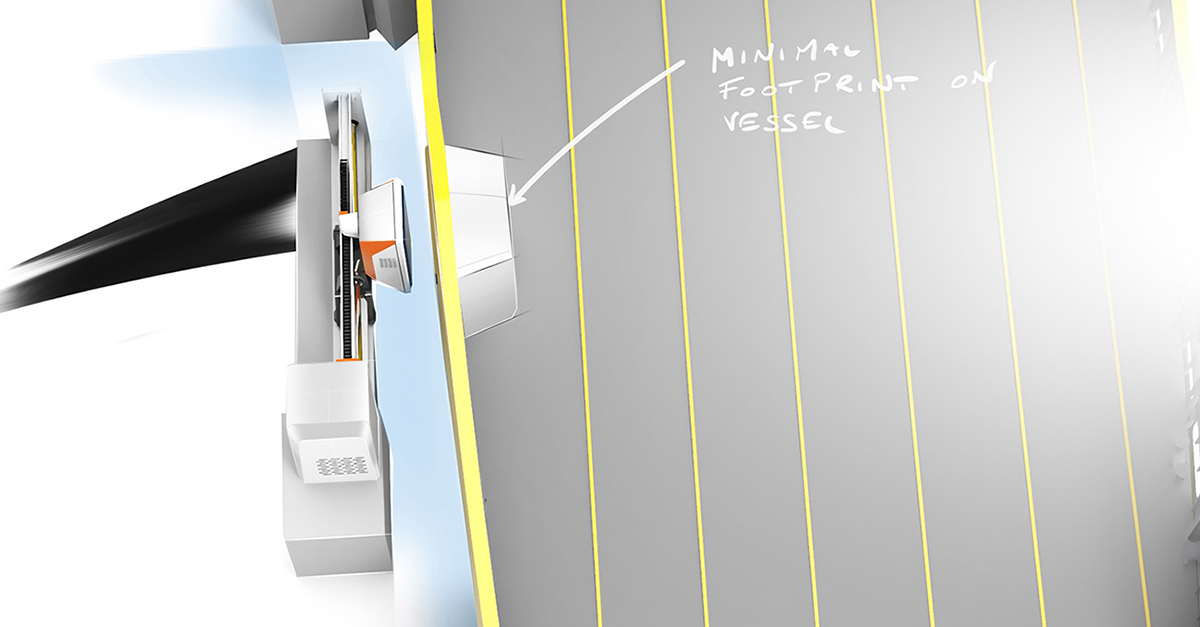

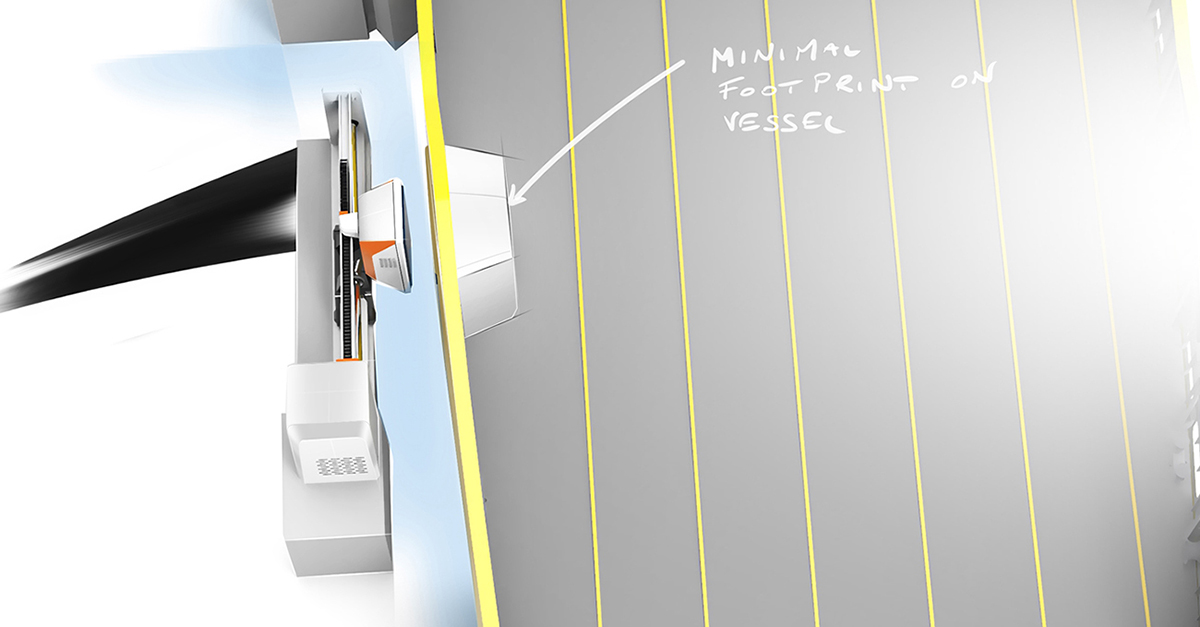

The Wärtsilä wireless vessel charging system replaces the traditional cable connection method. This type of marine battery charging system is particularly well suited to fully electric vessels that spend little time in port, such as ferries. Vessel charging can start the moment the ship docks, meaning that the same amount of energy can be supplied to the vessel over a longer time, reducing the total power rating requirement of the shore power charging station.

When combined with systems such as auto docking and vacuum mooring, docking and undocking becomes faster, safer and more efficient.

Wireless charging solution with tide compensation device

Frequently asked questions

2019_MB_Wireless_charging_FAQs

Expand all

More answers to common questions about wireless charging

Didn’t you find the answer you were looking for in the above FAQ section? Download this full document where we have gathered even more frequently asked questions and answers regarding Wärtsilä’s wireless charging system for easy transfer of power from shore to ship.