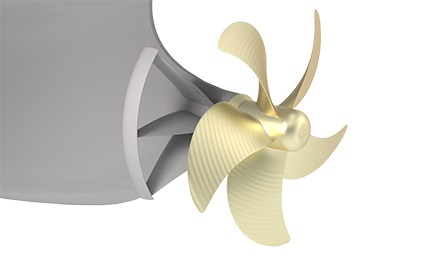

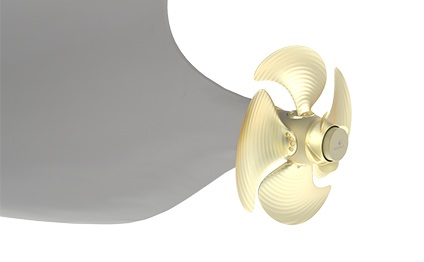

Fixed Pitch Propellers

Optimal performance and efficiency

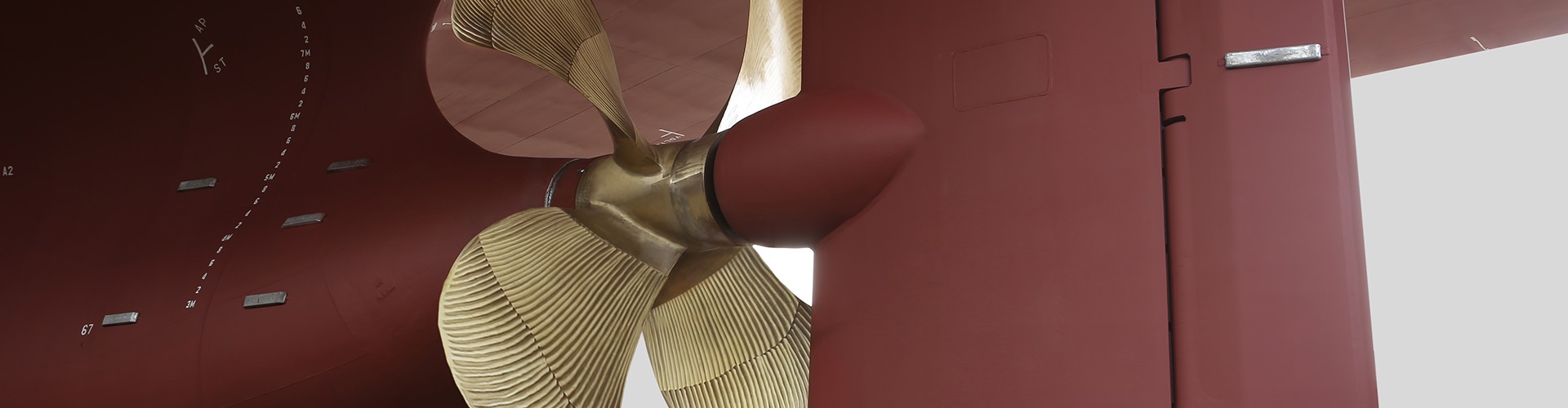

Wärtsilä Fixed pitch propellers are designed by a team of industry-leading in-house hydrodynamic experts plus each design draws on decades of experience and data from LIPS and Wärtsilä which is all integrated into to high-quality propeller design and production specific to each vessel and customer needs.

Propeller efficiency, noise, and vibration requirements are the main design considerations to ensure optimal performance for a wide range of speeds and power densities, and for any vessel type. The unique Wärtsilä Cunial® propeller material provides excellent casting, machining, and fatigue properties.

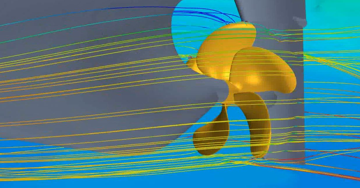

The propeller and shaft line design tools are based upon deep knowledge and experience with calculations, model test results, computational fluid dynamics (CFD), and full scale results. Bringing all these capabilities together ensures that every delivery is of the highest quality and performance standards.

Key benefits

- Optimal performance and efficiency, while minimizing noise and vibration levels

- Improved vessel EEDI/EEOI

- Tailor-made designs using the latest available technology

- Excellent hydrodynamic guidance

- Fixed pitch propulsion solutions for all power levels

- Minimised propeller weights with Wärtsilä’s unique Cunial® propeller material

- A reliable propulsion solution for all classification and applications

- Complies with EPA Vessel Permit 2013 requirements (EAL application)

- Available with pollution free stern tube arrangement

- Easy installation

- Easy to maintain, good reparability characteristics

- Increased fuel savings when used with Energopac, EnergoProFin and OPTI Design

Application

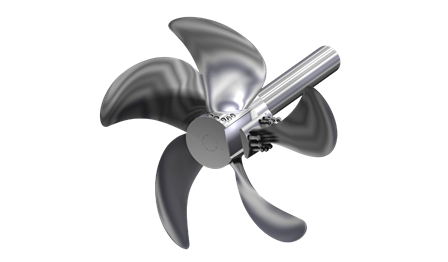

Monobloc Fixed Pitch Propellers are propellers casted in a single piece with the hub and blades. Wärtsilä FP propellers can be produced to meet all requirements regarding the number and size of the blades. The FP propeller guarantees maximum efficiency and minimum noise and vibration levels thanks to tailor-made designs using the latest available technology. The Cunial® material used provides excellent casting, machining, and fatigue properties. An additional advantage is the ease of reparability. A fixed pitch propeller is the choice when optimum efficiency, reliability and robustness are required. Fixed pitch propellers are usually installed for ocean going vessels, for example:

- Container vessels

- Tankers

- Bulk carriers

- Dry cargo vessels

- Passenger liners

Each ship’s hull has its own characteristics. In order to achieve the highest possible overall efficiency of the vessel, the propeller must be perfectly matched with the engine and hull. Propeller designs are always tailored to the specific application, and for this modern design tools are utilised by a vastly experienced hydrodynamic design team.

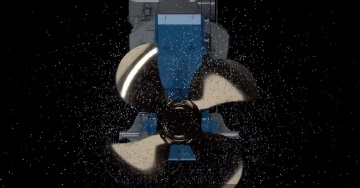

Wärtsilä’s hydrodynamic engineers are also specialized in high-end Fixed Pitch Propeller designs for more advanced applications, such as:

- Research vessels

- Navy vessels

These vessels commonly have typical requirements related to under water radiated noise levels.

For additional fuel savings, Wärtsilä Fixed Pitch Propellers can be equipped with Wärtsilä's fuel saving EnergoProFin propeller cap, or with Wärtsilä's optimised manoeuvring and propulsion Energopac solution. In cases where the propeller is heavily loaded, a High Performance Nozzle can be installed. OPTI Design produces even greater fuel savings by being able to thoroughly analyse the performance of both the propeller and the propeller-hull interaction.

Technical info

Replacement propellers

Wärtsilä's extensive design knowledge and modern design tools can enable significant efficiency increases when retrofitting propellers. Existing propellers that are based on older design principles or different operational conditions, such as slow steaming, can be replaced so as to reduce fuel oil consumption. Efficiency improvements of up to 15% are possible.

The main reasons for a propeller replacement are:

- Improved efficiency

- Change in operating profile, such as slow steaming

- The propeller is too severely damaged and cannot be repaired

- Upgrading of the propeller design to modern standards

- Lower propeller induced pressure pulses

- Poor initial design

Supply package

Each ship's shaftline has its own design and requirements. The propeller shaft installation has a proven and effective basic design, which enables easy installation:

- Hydraulic tool sets

- Hydraulic nut assembly

- Hydraulic ring

- Propeller and intermediate shafts

- Hydraulic coupling flange

- Hydraulic sleeve coupling

Shaftline accessories’ scope of supply

- Efficiency rudder (Energopac)

- High performance nozzle

- Propulsion control system

- Build-up propellers

- EnergoProFin

- Sterntube with or without bearings

- Seals and bearings

- Thrust bearings

- Torque measurement device

- Turning device

- Shaft grounding device

- Shaft brake

- Rope guard

- Net cutter

Consultancy

- Hydrodynamic optimisation and detailed propeller design

- Shaftline design

- Alignment calculation

- Whirling vibration calculation

- Jackload calculation

- Evaluation of jackload measurement