Introducing trigeneration in Cheong Soo

| Who | JB Enertek Co., Ltd |

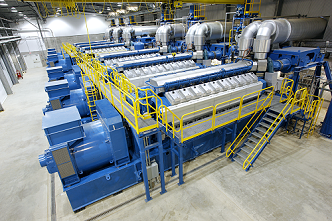

| What | 3 x Wärtsilä 20V34SG Flexible Baseload |

| Where | Cheong Soo, South Korea |

| How | EEQ (Engineered equipment delivery) |

This is what we achieved

MW of electrical output

MW of district heating output

Total operating efficiency

Cheong Soo CHP is the most successful engine plant in South Korea and we are very proud to supply power and heat to our customer by using Wärtsilä 20V34SG engines.

How we did it

Challenge

- Electrical load minimal but head demand maximum at night

- Electricity generation parallel to the grid

- Meeting the noise level and emission requirements set by Korean legislation

Solution

- Charging of heat accumulators during daytime and consumption of heat at night

- Wärtsilä 34SG gensets provide continuous and reliable energy

- Advanced emissions and noise reduction equipment were installed

Benefit

- Minimum 79% efficiency 24 hours a day

- Avoiding the costs of installing external site connections

- Compliance with regulations allows plant to operate efficiently and avoid potential penalties

The main details

| Customer | JB Enertek Co., Ltd (IPP) |

| Type | Wärtsilä 34SG gas trigeneration power plant |

| Operating mode | Flexible baseload |

| Gensets | 3 x Wärtsilä 20V34SG |

| Total output | 25 MWe + 21 MWth |

| Fuel | Natural gas |

| Scope | EEQ (Engineered Equipment Delivery) |

| Delivered | 2010 & 2015 |

Would you like to know more?

Contact us

Fill in a contact form and our experts aim to be in contact within 1-2 business days. Contact us »

Read our brochure

Read our product brochure to get all the details.

Related solutions and services

Related materials

Trusted partner to the best companies in the world

Related press releases

Wärtsilä delivers gas-engines for a power plant in South Korea

Wärtsilä was awarded a contract in May 2007 from JB Entech Co Ltd, South Korea, to deliver engineering and equipment for a 25.3 MWe combined heat and power plant (CHP) for the Cheong Soo community in Cheon Ahn City.

This is Wärtsilä’s first CHP project in South Korea under the CES (Community Energy System) concept, which is based on South Korean government legislation to encourage decentralized energy production. The CES aims to supply heat and electricity from independent heat and power production facilities to residential, commercial, business, and hospital buildings and facilities that are concentrated in a specific area.

Wärtsilä will deliver the equipment in two phases. The first phase requires two Wärtsilä 34SG gas-engined generating sets. In the second phase, Wärtsilä will deliver a third identical generating set, raising the total electrical output to 25 MWe and the thermal output to 21 MWth. Waste heat recovery from these engines will provide thermal energy for district heating and cooling.

The first phase of the plant is due to be operational in the second half of 2009, and the second phase around mid 2012.

For additional information, please contact Ms Eeva Kainulainen, VP Corporate Communications, tel. +358 10 709 5235.

Wärtsilä in brief:

Wärtsilä enhances the business of its customers by providing them with complete lifecycle power solutions. When creating better and environmentally compatible technologies, Wärtsilä focuses on the marine and energy markets with products and solutions as well as services. Through innovative products and services, Wärtsilä sets out to be the most valued business partner of all its customers. This is achieved by the dedication of more than 14,000 professionals manning 130 Wärtsilä locations in close to 70 countries around the world.