Marine solutions deliver value

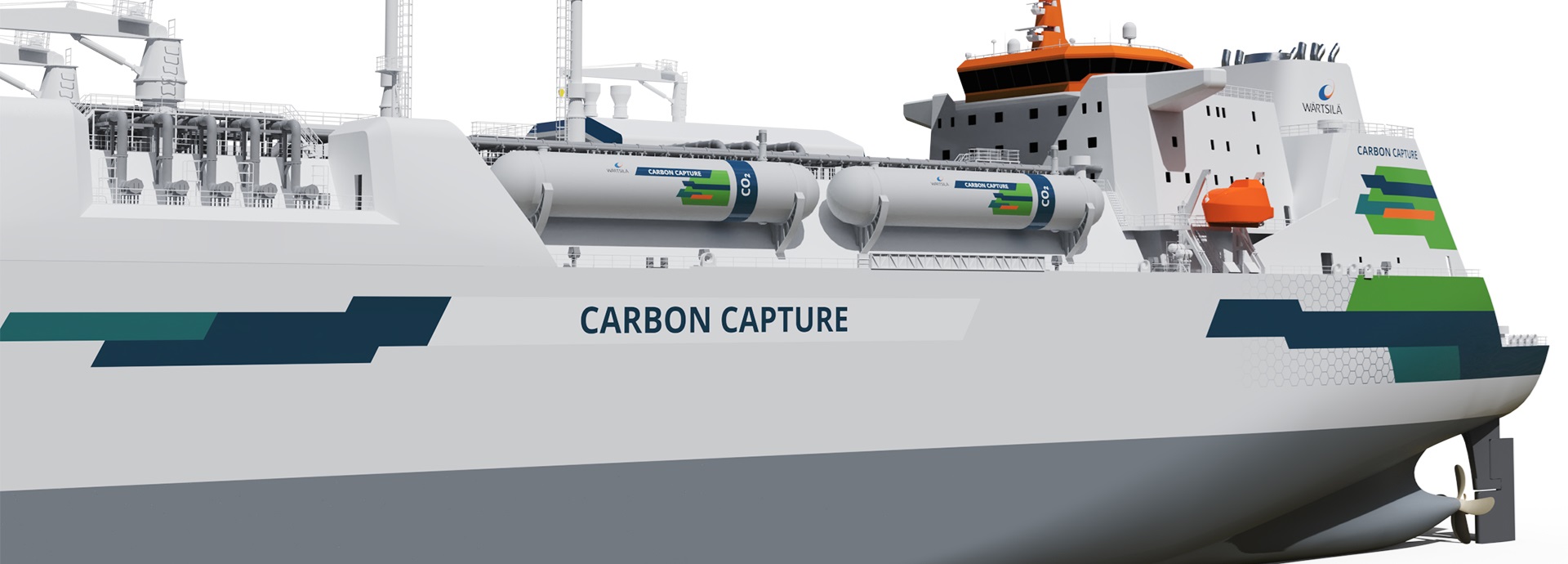

Marine technology, ship engines, and other solutions from Wärtsilä will help you run your maritime business profitably. Get vessel-specific insights or the entire fleet point of view to define the best decarbonisation strategy just for you.

Most popular next steps

Find Wärtsilä’s powerful, fuel flexible marine engines for your newbuilds. Get retrofits, upgrades, and fuel conversion for your current vessels. You can also opt for a unique service which can deliver savings in fuel consumption while lowering your emissions – guaranteed.

Sustainable fuels for shipping by 2050 – the 3 key elements of success

How to decrease the environmental footprint of shipping? What are the key actions that will keep the shipping industry on course to achieve net-zero by 2050?

Download this research-backed report on future fuels in the marine industry to find out:

Data and digital tools from Wärtsilä help smart vessels and ports operate more efficiently for the benefit of a seamless, safe and sustainable global supply chain.

Wärtsilä has an extensive portfolio of solutions for liquid and gas handling on vessels: ballast water management, freshwater generation, gas solutions, and exhaust treatment solutions.

Get your spare parts fast and cost-efficiently. Choose Wärtsilä spare parts, and you will enjoy market-leading part availability, premium quality and the expertise required to reduce downtime and future-proof your fleet.

Marine applications

Choose your business segment and you will find special products and solutions for you.

Webinars

Webinars for the hottest topics in the maritime industry. Register for upcoming webinars. Sign in to watch recorded webinars and download the materials.

Articles

Insights on the trending topics in the maritime industry.

Latest press releases

Customer stories

Did you know? Every third vessel sailing the oceans of the world has Wärtsilä solutions on board. Here you can discover Wärtsilä’s references from the maritime sector. Stories from customers ranging from cruise ships, ferries, bulkers, yachts, and merchant, navy, offshore, and special-purpose vessels.