How to predict and prevent problems before they cause downtime

Take advantage of vessel data – it will help improve the reliability of your marine assets. The right combination of tools, expertise and data will detect anomalies early on, and your crew can address them before they cause problems.

Predictive maintenance helps prevent problems

Wärtsilä Expert Insight service uses real-time vessel data to detect potential issues. It monitors the performance and behaviour of the engine system and uses this information for predictive maintenance.

Because it uses advanced AI and rule-based diagnostics, it will recognise problem symptoms very early on. It has learned to recognise behaviour patterns that predict a problem. It will then flag these to an expert, who will recommend maintenance that will prevent the problem.

You will have peace of mind because you know that Expert Insight will give you early warning. You can resolve minor symptoms or problems before they can become major issues. The result is increased safety, reliability and efficiency.

How does Expert Insight make your maintenance activities more predictable?

Watch the video to find out:

Key benefits

- You will have actionable data for the basis of your decisions

- The vessel will be more reliable and available

- The service will reduce unscheduled downtime

- You can avoid costly repairs

- The vessel will operate more efficiently thanks to predictive maintenance

Because the online service lets your office-based and onboard crew collaborate with Wärtsilä experts, you will get better and more transparent support for your daily operation.

How does Wärtsilä Expert Insight work?

Expert Insight uses AI and rule-based diagnostics combined with expert analysis.

The AI algorithms will compare the real-time data from your vessel to its unique operating profile. Because it has learned to detect anomalies, it can spot problems early on.

The rule-based detection is based on rules that define the boundaries of optimal equipment behaviour. The boundaries are based on equipment configuration, design recommendations and field experience with the equipment.

The AI and rule-based diagnostics will detect tiny deviations and patterns that no human can notice. If they flag an anomaly, the assigned Wärtsilä experts will investigate the issue and then recommend actions for the crew via the online app.

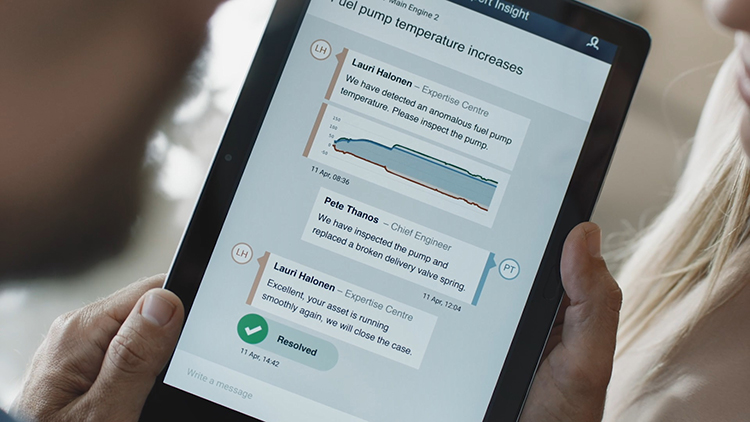

The online app lets the on-board crew and the onshore personnel collaborate with the Wärtsilä expert and follow the progress of cases. They can chat with the experts and get the support they need for solving the issues.

The vessel's operational data, and trends are also available in the online app. This way, your personnel can easily see how the equipment is performing.

The online app has a chat functionality

How early detection and remote support work in real life

December 2020: The diagnostic expert sees indications of a potential problem that could affect the shuttle tanker Aurora Spirit, sailing close to Stavanger, Norway.

Anomaly detection

Because the vessel is connected to Wärtsilä Expert Insight, the Expertise Centre staff notice an abnormal lube oil pressure at the turbocharger inlet in an engine onboard the vessel.

Remote troubleshooting

The expert team analyses the situation and identifies the reason: there is a bearing failure on the turbocharger compressor side. The operational support team uses a remote connection to guide the crew to take corrective action.

Problem solving

The crew replaces the bearing, and the engine continues to operate as it should.

Expert Insight identified that there could be an issue. The crew were able to take corrective action and avoid bigger problems.

This incident demonstrated not only the value of Expert Insight, but also the dedication of the Wärtsilä team in verifying the problem and coming up with a solution in a very short timeframe.

How to get started with Expert Insight

Expert Insight is available as part of service agreements for Wärtsilä 4-stroke and 2-stroke engines. It is delivered globally through Wärtsilä Expertise Centres, where experts are available round-the-clock, safeguarding the reliability of your vessel.

A cyber secure connectivity means that it is possible to continuously monitor your vessel's operational data. It is also the enabler for remote support that your crews can get from Wärtsilä experts.

Related products and services

You may be interested in the following related services included in Wärtsilä Lifecycle Agreements:

Customer stories

Discover the benefits others already gained from Expert Insight.

Insights on predictive maintenance

Discover these insightful articles and stories - they will build your knowledge on data-driven and predictive maintenance.

Discover the power of vessel data and take an easy first step in improving the reliability of your marine assets. Get in touch and let's discuss your needs and options!