Thruster maintenance for Noble drillships

Noble, a world leader in offshore drilling, entrusted Wärtsilä with the thruster maintenance programme for its entire fleet of D-rig semisubmersibles and V-rig drillships. The thruster maintenance programme is divided into three steps: removing the units from the rigs, refurbishing the removed units ready for reuse and fitting new or refurbished units on the rigs. Watch the video to see why meticulous planning and close collaboration were vital to the success of the thruster exchange for the Noble Voyager V-rig drillship.

Programme scope

- Maintenance programme for a total of 62 thrusters (48 operating units, 14 spare units)

- Thruster exchange, replacement and upgrade

- Complete turnkey project service including Wärtsilä Underwater Services support for vessel Special Periodic Survey (SPS), project management, lifting/strandjack services and logistics services

High-quality OEM maintenance for mission-critical thrusters

Thrusters are the beating heart of any modern drillship. These sophisticated propulsion systems enhance manoeuvrability, enabling complex movements and station-keeping in deep water environments. For Noble, the thrusters on their vessels are mission-critical systems with a direct impact on operational success, safety compliance and financial performance.

Noble operates one of the most modern, versatile and technically advanced fleets in the offshore drilling industry. Its fleet of D-rig semi-submersible vessels and V-rig drillships relies on Wärtsilä thrusters to provide unparalleled dynamic positioning capabilities, enhanced manoeuvrability and critical operational support.

Wärtsilä thrusters provide the dynamic positioning capability that allows Noble’s vessels to maintain their position over drilling sites even in extremely challenging ocean conditions. Noble trusts Wärtsilä to provide high-quality OEM maintenance to keep the thrusters onboard their vessels operating reliably.

New and upgraded thrusters for the Noble Voyager

When Noble needed a partner for a comprehensive thruster maintenance programme across seven of its most important rigs – including three semi-submersible D-rigs and four drillships (V-rigs) it turned to Wärtsilä. The programme covers maintenance for 62 thrusters, with 48 operating units and 14 spare units.

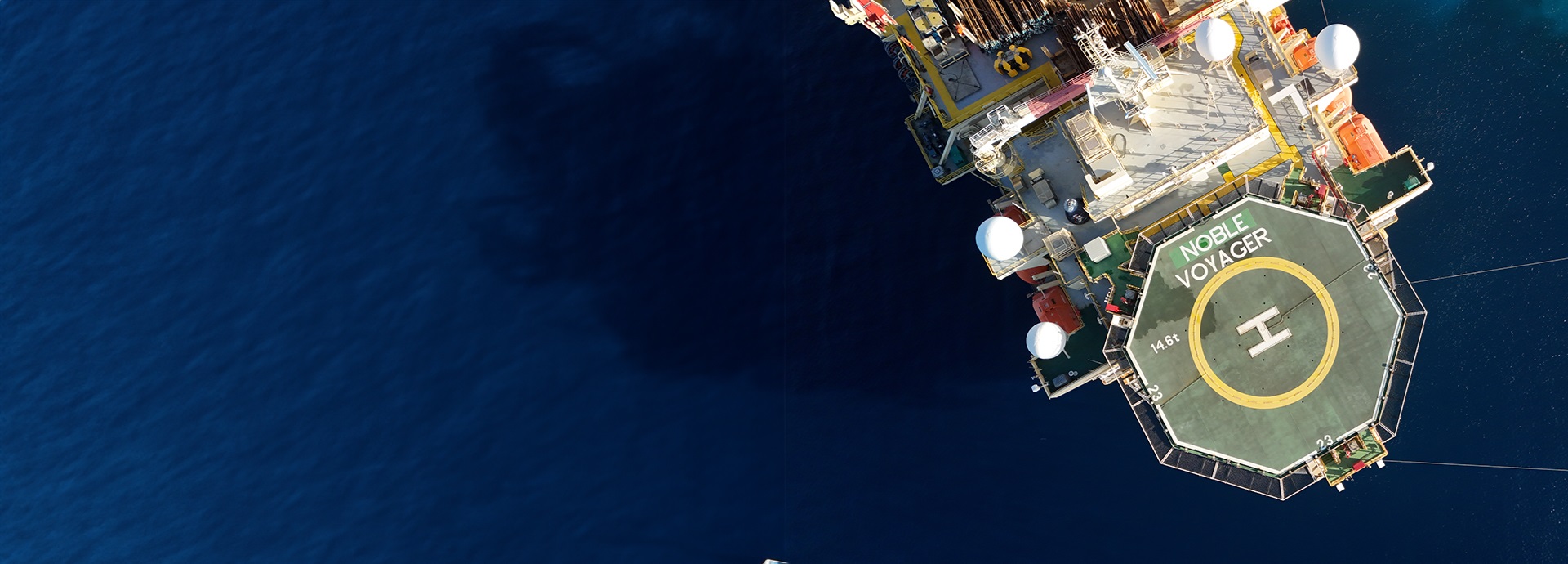

One of these rigs is the Noble Voyager, commissioned in 2015. This colossal Samsung 96-k design drillship, built in 2015, can operate in waters of up to 3,658 m (12,000 ft) and is capable of drilling to depths of up to 12,192 m (40,000 ft). After 12 months of meticulous planning and preparation, the Noble Voyager arrived at the Caribbean island of Curaçao for critical maintenance, including underwater inspections in place of drydocking.

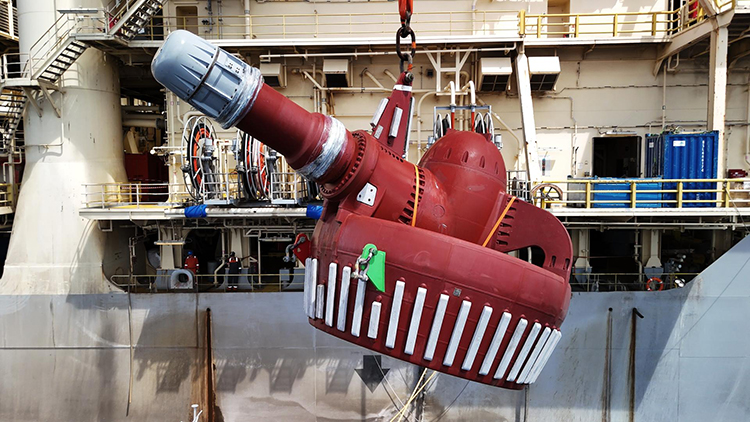

Waiting in Curaçao was a 30-strong team of thruster and underwater service experts from Wärtsilä. Three of the vessel’s six thrusters would be replaced with new units built at Wärtsilä’s workshop in the Netherlands, and three replaced with units upgraded at Wärtsilä’s workshop in Norway. With a huge amount of diving work involved in the thruster exchange, the warm, calm seas around Curaçao provided the perfect working environment for this challenging and complex project.

Project completed in just 28 days

A thruster exchange takes a drillship out of service, which means these expensive assets aren’t making money at any point during the exchange. World-class project management is therefore worth its weight in gold in this kind of programme. Once the Nobel Voyager’s six thrusters, each weighing around 60 tons, had made their way from the Netherlands and Norway to Curaçao, the team had just 28 days to perform both the thruster exchange and the Underwater Inspection in Lieu of Drydocking (UWILD).

With divers in the water, barges and tugboats moving around and vast weights being lifted with heavy rigging equipment, safety and precision coordination within the large team were top priorities. Experts from Wärtsilä Underwater Services played a critical role in executing the exchange.

Long-standing relationship the foundation for success

The relationship between Noble and Wärtsilä has been built and developed over many years of working together, and is based on trust and open, honest communication. These values, together with the vast expertise and experience of the Wärtsilä thruster services team, provide rock-solid foundations for success.

Once the new thrusters were successfully installed, the six thrusters removed from the Noble Voyager then began their journey back to the Netherlands and Norway for upgrading in Wärtsilä’s workshops.