Widest offer of fresh water making technologies in the marine industry

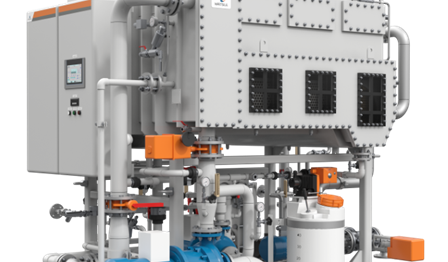

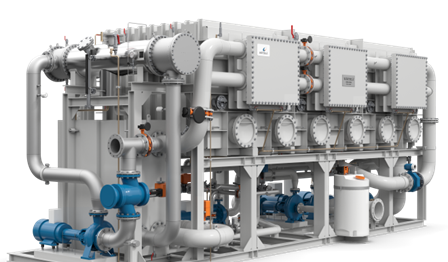

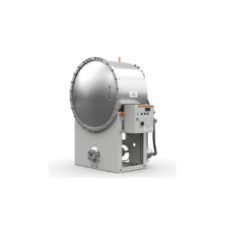

Within the marine world Wärtsilä’s Fresh Water Generators (FWG) are known as standard for on-board freshwater production. Ship owners, builders and operators can source from the widest range of freshwater making technologies available to the market today. This range includes Reverse Osmosis plants, Multi Flash Evaporators, Horizontal inner Tube Evaporators, Single Stage Desalination plants, or a combination of these. Also a growing number of land-based applications is fitted with our equipment. In choosing Wärtsilä as your freshwater production partner you secure a flexible, reliable and fully automated solution.

Product range

Specialist solutions require high customer focus

Our diverse and dedicated team of engineers is developing, manufacturing and distributing freshwater solutions for and to customers worldwide. Thanks to a creative out-of-the-box mindset, this team excels in innovative and specialist solutions, bespoke set-ups that require a high customer focus.

Every successful implementation of a fresh water generator starts with an accurate analysis of the vessel's status, identifying possibilities and needs. In each case our team will strive for a solution that is most energy and space efficient. A higher energy efficiency, for instance, can often be reached by looping to energy sources already available on a vessel. Greater flexibility in construction and sizing can be accomplished by making a combination of different FWG technologies. This approach especially comes in handy when retrofitting engine rooms.

Over 125 years of experience in designing & manufacturing fresh water generators for the marine industry

Building on more than 125 years of history

Our freshwater division in Geesthacht, Germany, is also known as Wärtsilä Serck Como GmbH and part of the bigger Wärtsilä Water & Waste business unit.

The company’s expertise in freshwater generation is unrivalled: in 1894 Serck Como started producing its first evaporator for sea-going vessels. Having survived two world wars, we know what it means to adapt to ever changing circumstances. We believe that it is important to both invest in own innovations and to adapt to new external trends. As water maker specialist our focus is on the future. We are confident to come up with new solutions for technical challenges that may come our way.

Total water & waste solution

Fresh water generators form a part of a much wider water & waste product range, offered by Wärtsilä’s eponymous “Water & Waste” business unit. Ship owners, builders and operators that are looking for a single provider for all their water, waste and wastewater challenges, will find the peace of mind they are looking for with us.

In addition to fresh water generators, our total solution offer includes ballast water treatment technologies, wastewater, wet and dry waste treatment systems. Thanks to Wärtsilä Water & Waste’s global agents and distributors network, our after-sales and spare parts services are reliable and well organised. We are able to help our customers from the design phase of their freshwater equipment to the delivery of spare parts.

For NEWBUILD, please contact +49 4152 805-0 or waw.sales@wartsila.com

For SPARE PARTS, please e-mail us with the Equipment Serial Number or the name of the vessel at wsc.aftersales@wartsila.com. For urgent support, contact +49 4152 805-130.

For TECHNICAL SUPPORT & SERVICE, please email us with the Equipment Serial Number or the name of the vessel at wsc.aftersales@wartsila.com. For urgent support, contact +49 4152 805-226.

Equipment Serial Number is taken from the equipment nameplate and includes all letters and numbers as given on the equipment nameplate.