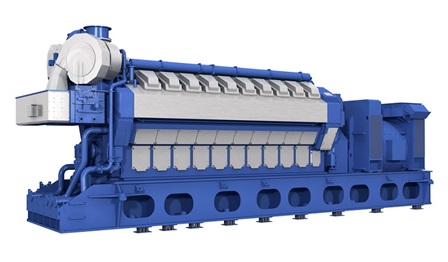

Ittehad Chemicals Limited (ICL), established in 1962, is a pioneer and one of the largest manufacturers of industrial chemicals in Pakistan. As a reliable energy source is essential for its chemical processes, the company has its own 30 MW power plant, comprising five Wärtsilä 18V34SG natural gas powered engines. The power plant is located at Ittehad Chemicals Ltd, near Lahore in Pakistan.

In Pakistan, the Ittehad Chemicals’ power plant and the national grid were operating at different frequencies. This meant that the company was forced to shut down the chemical process whenever it had to shift between the two sources of power. The result of these interruptions was a serious shortfall in production. Fortunately, the problem was solved by Wärtsilä, who successfully implemented a frequency conversion and control system upgrade. “We wanted to be able to run our power plant on 50 Hz, so that we could easily synchronise with the grid supply and switch smoothly between the sources of electricity,” says Sajjad Ahmad Khan, Head of Engineering at Ittehad Chemicals Ltd.

Fast forward to 2024, Wärtsilä successfully completed another upgrade to the five engines. This Power & Efficiency upgrade improved the power plant’s output by 20%, resulting in savings in operational costs and reduced derating of engine output.

A reliable power plant is Ittehad’s lifeline

Pakistan faces regular power outages and load shedding due to imbalances in supply and demand. According to Sajjad Ahmad Khan, this justifies having a power plant. As steam is also important for the process, waste heat recovery steam generators produce steam at a very low cost. The national grid in Pakistan runs at 50 Hz, whereas ICL’s power plant operated at 60 Hz, making synchronisation impossible. Eventually, ICL decided to go ahead with a frequency conversion after their natural gas supplier started curtailing supplies every week.

– We had to shut down the pro-cess plant twice a week to shift to grid supply and back upon gas restoration. These interruptions resulted in severe plant outages and a shortfall in production. We needed to be able to smoothly change over from one supply to the other, says Sajjad Ahmad Khan.

In addition, the upgrade of the old WECS 3000 control system was necessary because it had become obsolete. The upgrade to the Wärtsilä UNIC engine control system for gas and dual-fuel engines provided better features and more reliability.

ICL is active in a continuous process industry, where electricity is a necessity 24/7. Electricity is also the major cost contributor. In addition, power interruptions have severe negative effects on the main equipment used in the electrolysis process for sodium hydroxide.

– For Ittehad it is neither cost effective nor reliable to use the grid supply. Electricity makes up 65 – 69% of the production costs, and generated by our power plant it costs 25% less than the grid supply. Therefore, it is considered to be our lifeline, says Sajjad Ahmad Khan.

During the most recent upgrade, the 34SG engines got new camshafts, allowing the engines to cope better at high temperatures. The camshafts increased the compression ratio to 12:1, further raising engine efficiency. Additionally, new pre-chambers were added to the engines to improve both efficiency and running stability. Also the turbochargers were upgraded to a latest model, saving costs over time. The upgrade overall broadened the generator output from 5100 kW to 6600 kW and lowered the heat rate of the generator.

Projects delivered according to schedule

It was ICL’s prerequisite that the project would be done in the winter, since there is no gas supply during that season. Consequently, the delivery and execution schedule for the upgrade project was very tight in order to ensure that the power plant would be back online with the restoration of a natural gas supply.

Wärtsilä replaced the 60 Hz alternators with new 50 Hz alternators. In addition, the cooling fans were changed as per new requirements and the control system was upgraded to the new Wärtsilä UNIC engine control system – with improved communication between the generating sets and operator interface. Wärtsilä also provided a tailor-made load management system for switching between the grid and the power plant according to the connected load.

– Thanks to this upgrade, it is now possible to synchronise between the grid and the power plant, enabling both sources of power to run simultaneously; and it is easy to make a smooth changeover from one source to the other. From our point of view, it was a successful project, and despite a tight delivery and execution schedule, the project was delivered in time, says Sajjad Ahmad Khan.

According to Mr. Khan, the biggest benefits for ICL with this conversion are the availability and utilization of power, which both increased to more than 95% depending on the natural gas availability.

– Furthermore, the cold cylinder operation feature with this control system gives us time to plan maintenance instead of immediately shutting down the engines as we did before.

Shutdowns because of cylinder knocking or variations in exhaust temperatures are eliminated in this version, which gives the operator time to plan and react. This feature has highly increased reliability.

Wärtsilä understands our needs

Ittehad Chemicals has signed a Parts predict agreement with Wärtsilä, lasting until 2028. Sajjad Ahmad Khan says that the professional approach and understanding of customer needs is the best part of Wärtsilä Services. The service engineers are well versed with their products and trained to deliver.

Currently Ittehad Chemicals is under Parts and Predicts agreement with Wärtsilä. When asked to describe the cooperation with Wärtsilä, Mr. Khan says:

- I have interacted with Wärtsilä’s people for nine years and they have been very cooperative and real solution providers. The best part is that they are always willingly responding whenever we have issues.

– Pakistan is a country where electricity is scarce and therefore we need a reliable partner such as Wärtsilä to supply equipment for electricity generation. Wärtsilä is one of the best in aftersales services and they understand our needs better than anyone else, concludes Sajjad Ahmad Khan.