Wärtsilä + EDL – A continuing and long-lasting partnership

The McArthur River Mine in Australia, is one of the world’s largest providers of zinc in bulk concentrate form. Global energy producer EDL is responsible for supplying power to the mine. Wärtsilä has been a trusted partner for EDL for many years now, delivering gas engines and providing lifecycle services for condition-based maintenance to the power plant. The end result is better fuel efficiency, a low levelised cost of electricity, lower OPEX and guaranteed availability.

This is what we achieved

MW of electrical output

High ambient temperature

Months fast-track delivery

EDL is committed to delivering on our customers' expectation for reliable, cost-effective and environmentally sustainable energy and Wärtsilä's approach should help us achieve this. We expect the new agreement will help us to increase efficiencies, which in turn benefits our customer with greater reliability and reduced downtime.

How we did it

Challenge

- To ensure reliable electricity supply in an environment with high ambient temperature (+45°C) and large load acceptance requirements of varying quality

- To ensure high power generation availability and optimised OPEX of varying quality

Solution

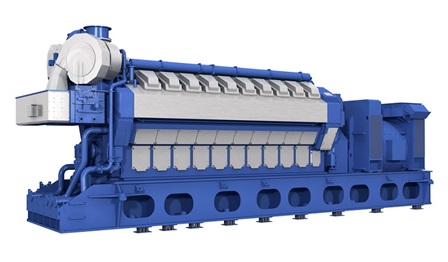

- Wärtsilä’s efficient and proven 20V34SG gas engines, and a multi-unit plant

- A 10-year service agreement for technical support, condition-based maintenance and maintenance planning, renewed as needed to meet the customer’s changing needs

Benefit

- High power output and efficiency resulting in the lowest levelised cost of electricity over the mine’s lifetime of varying quality

- Maximised availability, ensured reliable electricity supply and reduced operating costs of varying quality

The main details

| Customer | EDL (IPP) |

| Type | Wärtsilä 34 gas power plant |

| Operating mode | Baseload |

| Gensets | 6 x Wärtsilä 20V34SG |

| Total output | 53 MW |

| Fuel | Natural gas |

| Scope | EEQ (Engineering & Equipment) |

| Delivered | 2014 |

| Lifecycle solution | A 10-year maintenance agreement, renewed and extended in 2019 |

Would you like to know more?

Contact us

Fill in a contact form and our experts aim to be in contact within 1-2 business days. Contact us »

Read our brochure

Read our product brochure to get all the details.

Related solutions and services

Related materials

Trusted partner to the best companies in the world

Similar references

Related press releases

Wärtsilä’s long-term service agreement with EDL in Australia renewed and extended in response to developing needs of a zinc mine

Wärtsilä signs landmark long-term service agreement for Australian power plant

Wärtsilä to supply Australian mining site with 53 MW gas power plant expansion